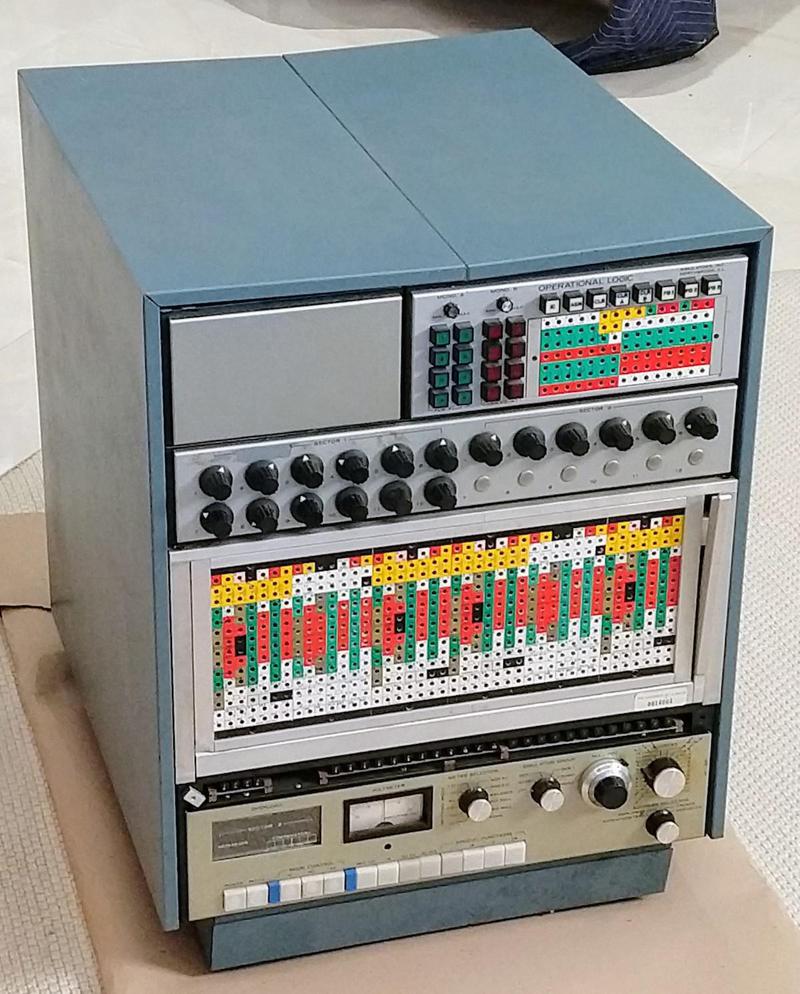

We are restoring a vintage1 computer that CuriousMarc recently obtained. Analog computers were formerly popular for fast scientific computation, but pretty much died out in the 1970s. They are interesting, though, as a completely different computing paradigm from digital computers. In this blog post, I'm going to focus on the op amps used in Marc's analog computer, a Simulators Inc. model 240.

What's an analog computer?

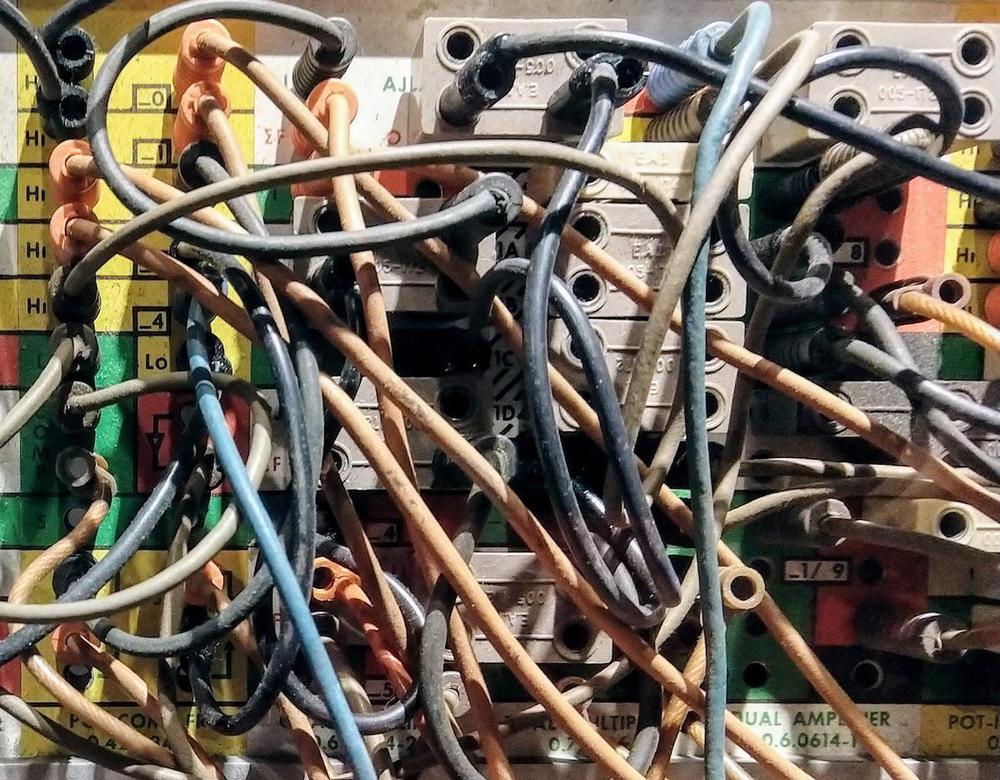

An analog computer performs computations using physical, continuously changeable values such as voltages. This is in contrast to a digital computer that uses discrete binary values. Analog computers have a long history including gear mechanisms, slide rules, wheel-and-disk integrators, tide computers, and mechanical gun targeting systems. The "classic" analog computers of the 1950s and 1960s, however, used op amps and integrators to solve differential equations. They were typically programmed by plugging cables into a patch panel, yielding a spaghetti-like tangle of wires.

The big advantage of analog computers was their speed. They computed results almost instantaneously with their components operating in parallel, while digital computers needed to chug away performing calculations, often for a long time. This made analog computers especially useful for real-time simulations. A disadvantage of analog computers is they were only as accurate as their components; if you wanted 4 digits of accuracy, you needed expensive 0.01% accurate resistors. (In contrast, digital computers can be made as accurate as desired simply by using more bits of precision.) Unfortunately for analog computers, digital computers became exponentially faster and more powerful, so by the 1970s there was little reason to use analog computers.

Inside the analog computer

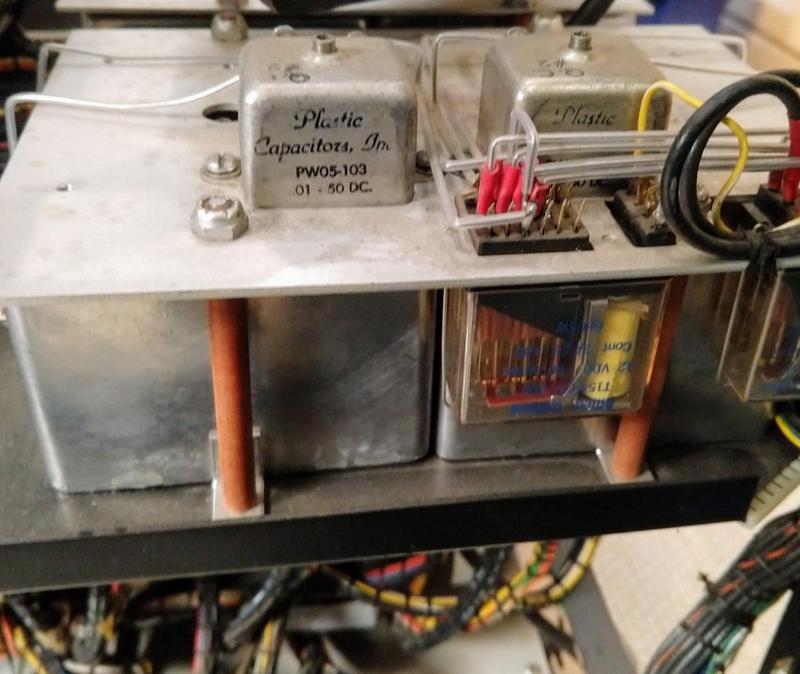

The heart of the analog computer was its operational amplifiers or op amps. Op amps could sum and scale their inputs, providing basic mathematics. But more importantly, integrators were constructed by combining an op amp with a precision capacitor (below). An integrator computed the integral of its input over time by charging the capacitor. This allowed analog computers to solve differential equations. (It may seem strange that integration, a mathematically sophisticated operation, was a basic building block of analog computers, but that's the way the hardware worked out.)

Analog computers used multiple potentiometers (below) to set input values and scaling constants. These potentiometers rotated through 10 turns to provide high accuracy. A voltmeter was used to check the potentiometer values. The voltmeter could also be used to display output values, but more often, outputs were displayed on an oscilloscope, strip chart, or X-Y plotter.

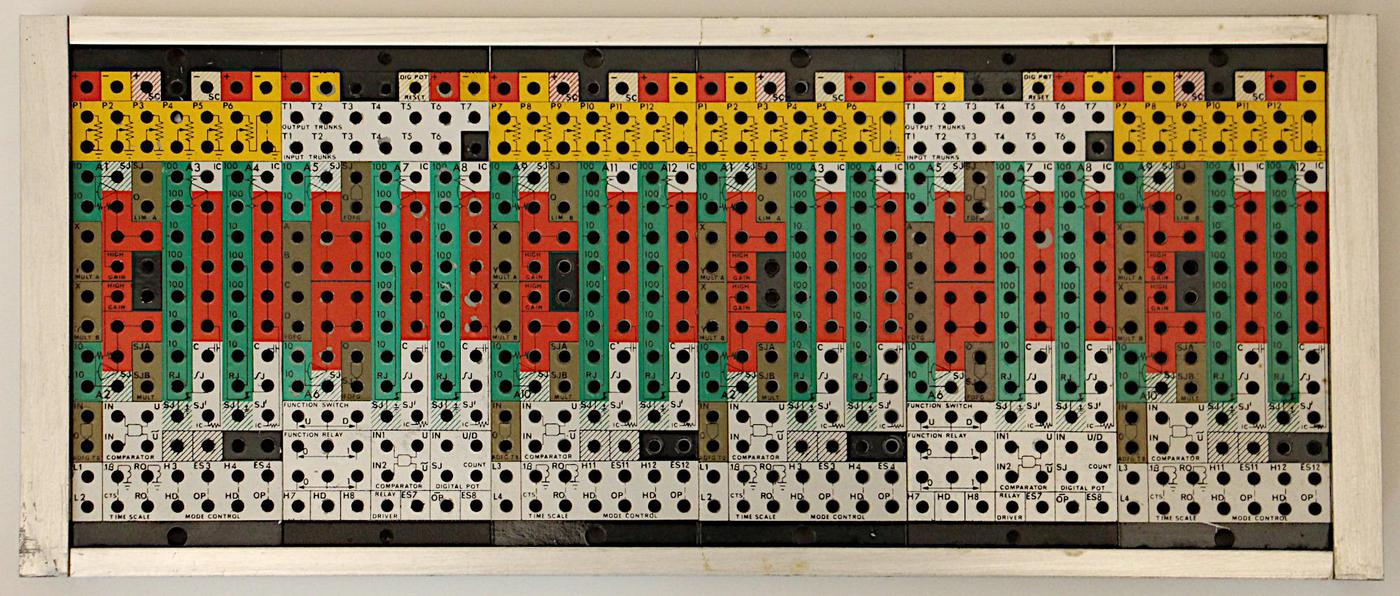

Some analog computers included digital components such as gates, flip flops, one-shots, and counters. This functionality supported more complex techniques, such as iterating through a solution space. Marc's computer has some digital logic, accessed through the colorful patch panel shown above.

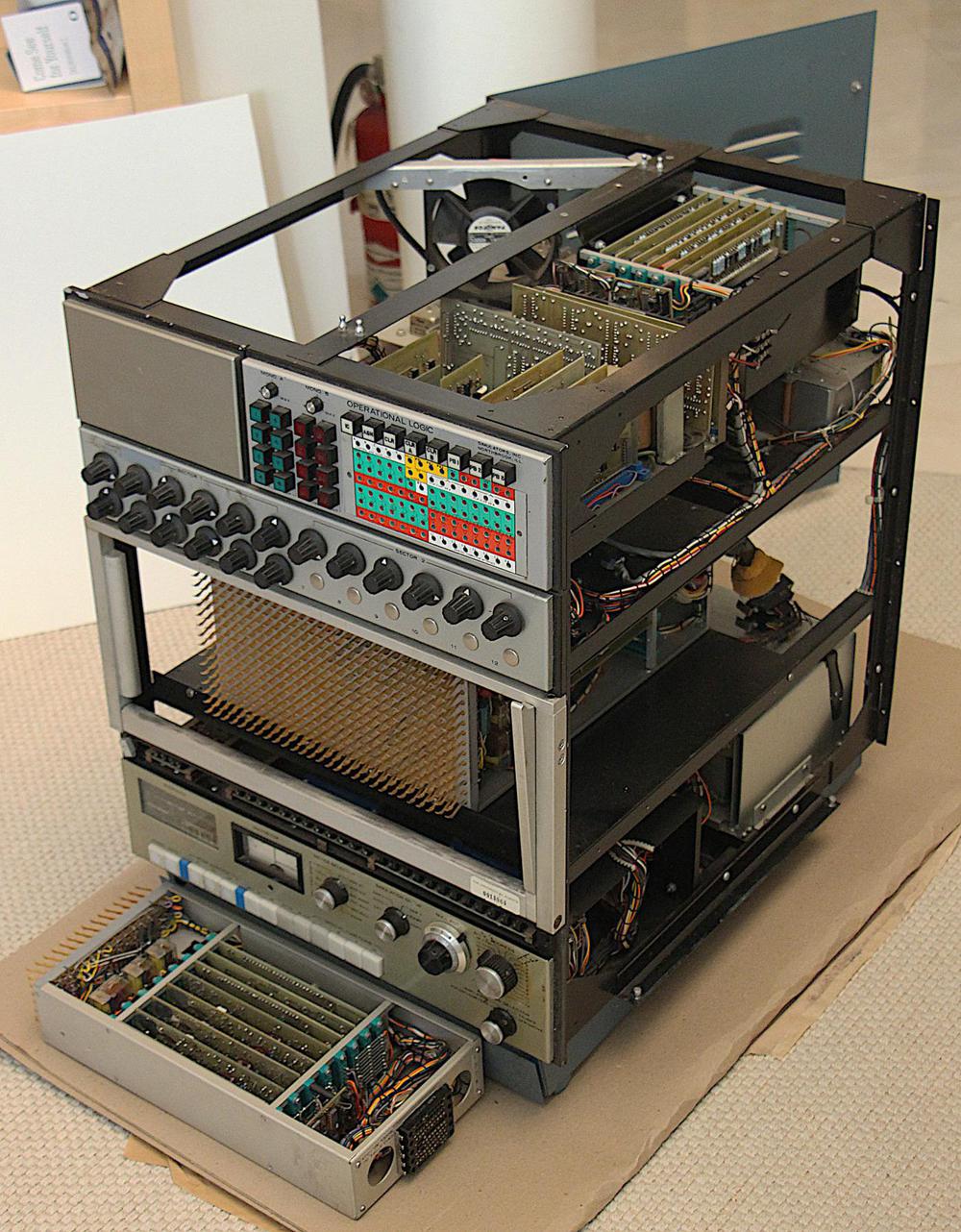

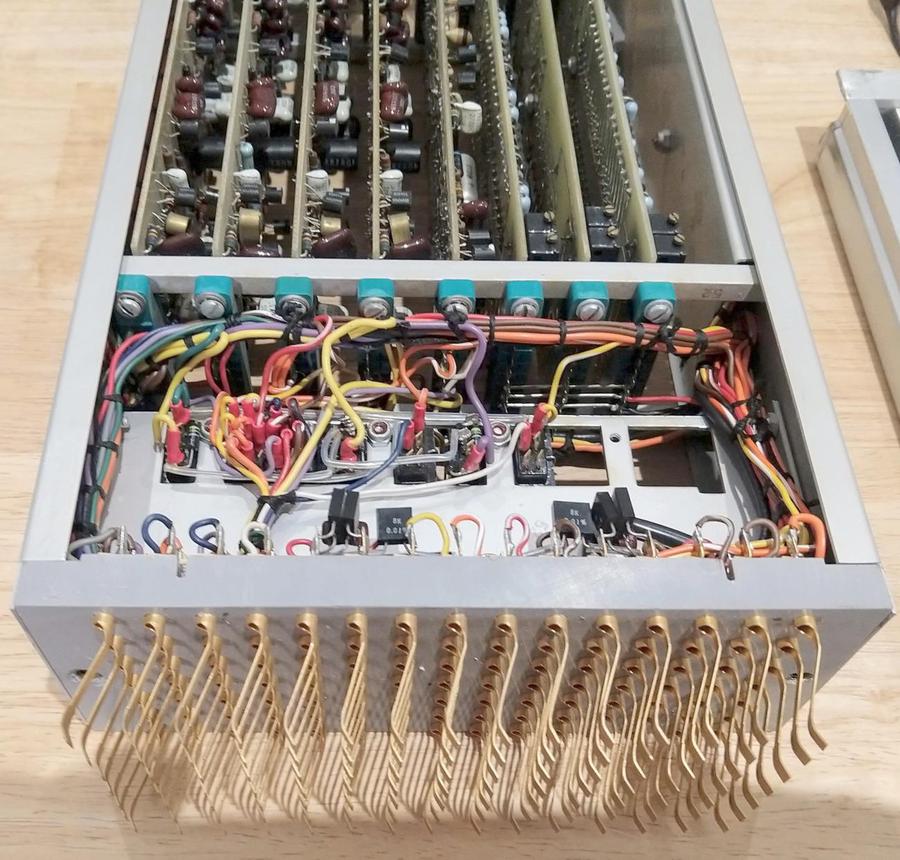

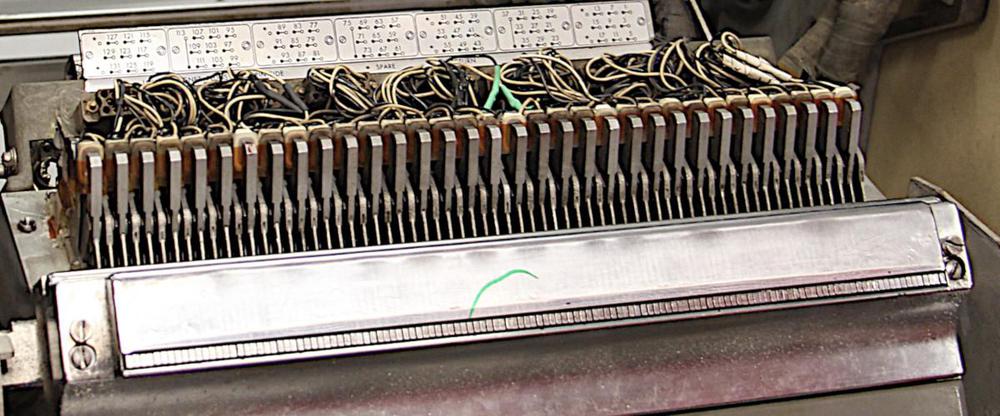

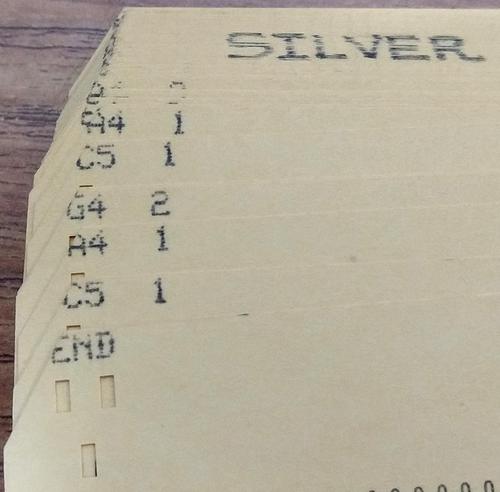

The photo below shows the computer partially disassembled. The computer is more complex inside than I expected, with many circuit boards. The patch panel has been removed, revealing the grid of contacts behind it. When a cable is plugged into the patch panel, the cable connects to these contacts, wiring up the program. The computer has five modules behind the patch panel; the leftmost module has been removed and is sitting in front of the computer.2 The boards visible at the top of the computer support the digital logic and two analog multipliers. The power supply and circuitry for the front panel are at the bottom.

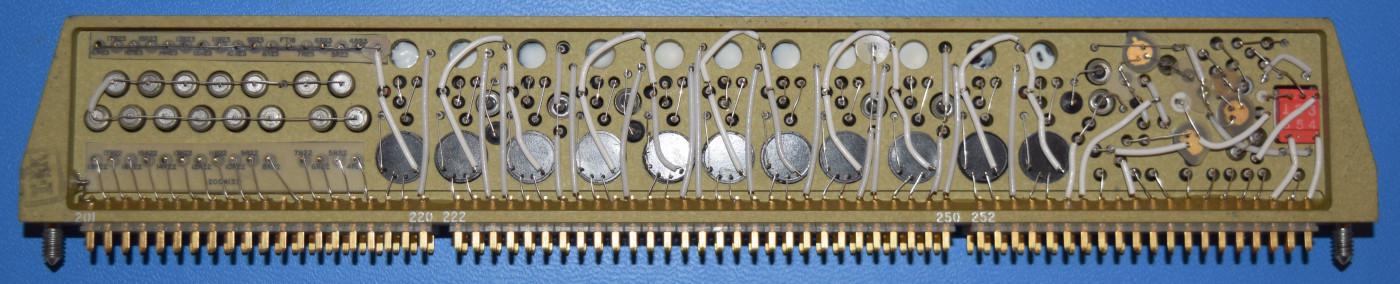

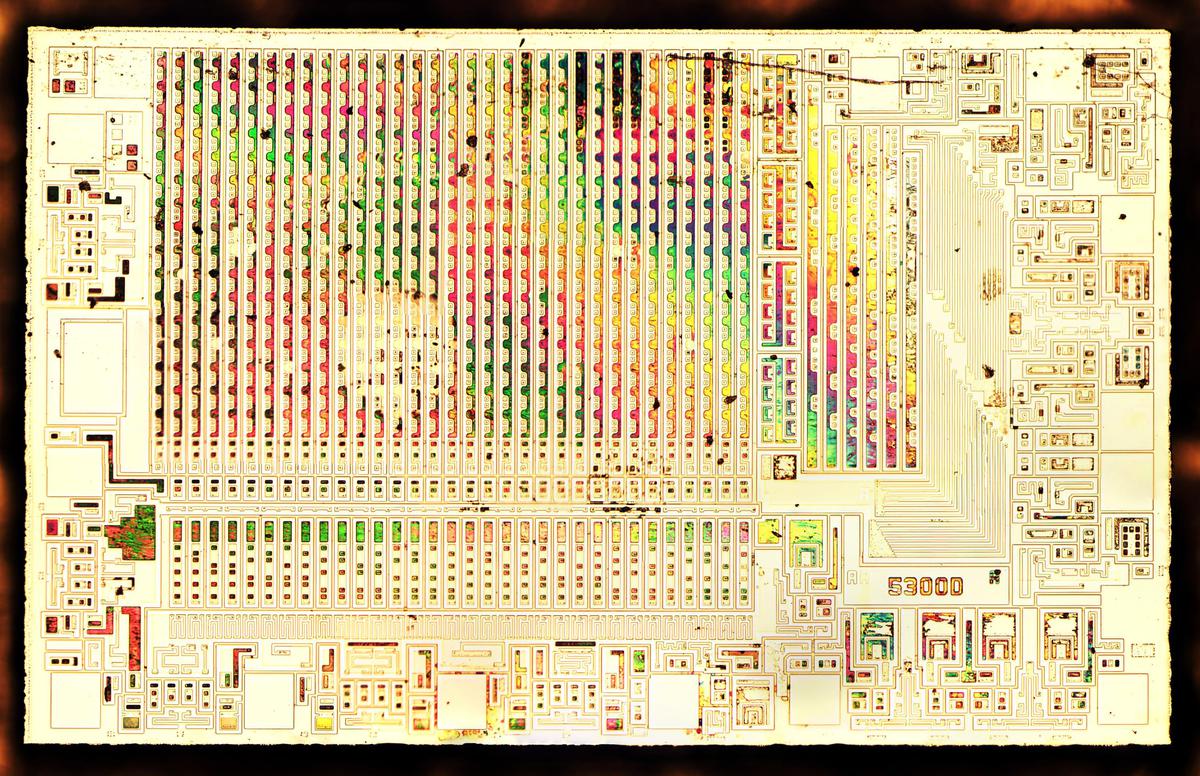

A closeup of a module is shown below, with the patch panel contacts in front. The module's eight circuit boards can be seen at the back. From left to right, the boards are four op amps (4 boards), miscellaneous circuitry (1 board), and a multiplier (3 boards). Multiplication was surprisingly difficult to implement in an analog computer; the three boards implement a single circuit to multiply two values.3

The op amps

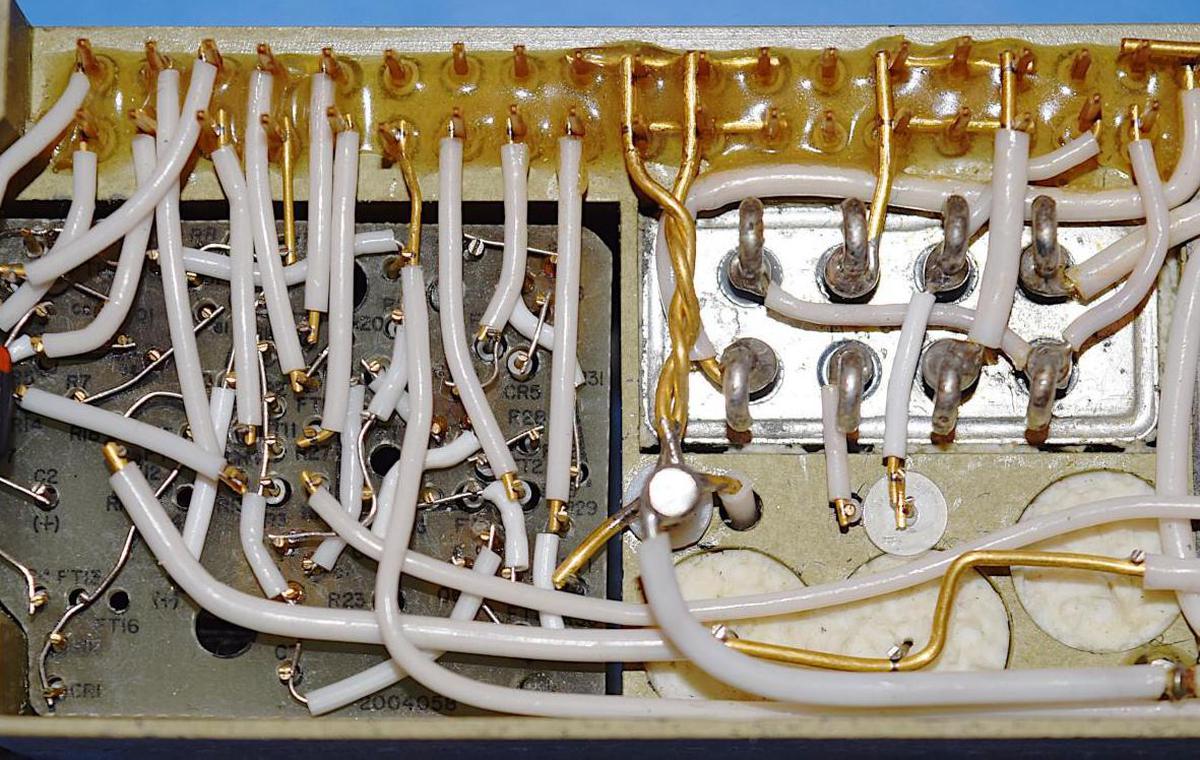

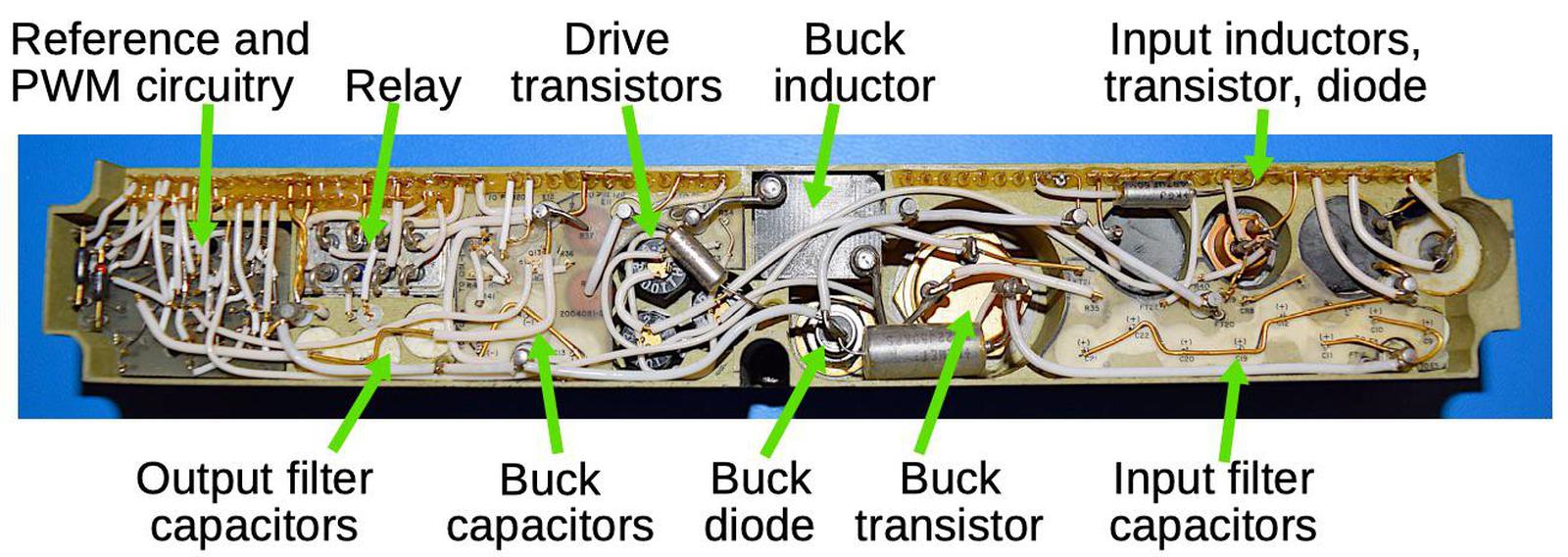

In the above photo, each op amp took up a full board of components. Each board includes an op amp integrated circuit, which raises the question of why so many other components are required. The reason is that analog computers placed heavy demands on op amp performance. In particular, the op amps need to work with signals at DC and at low frequencies, and op amps inconveniently perform poorly in this range, operating better at higher frequencies.

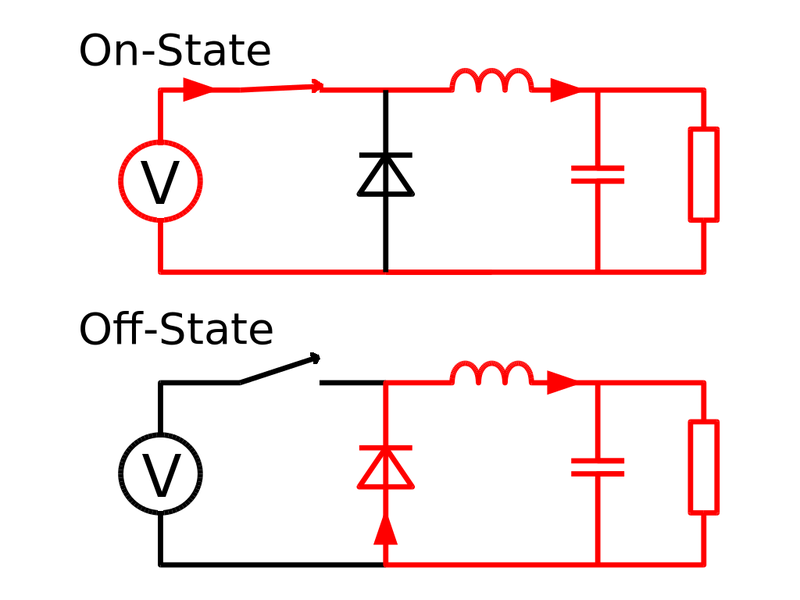

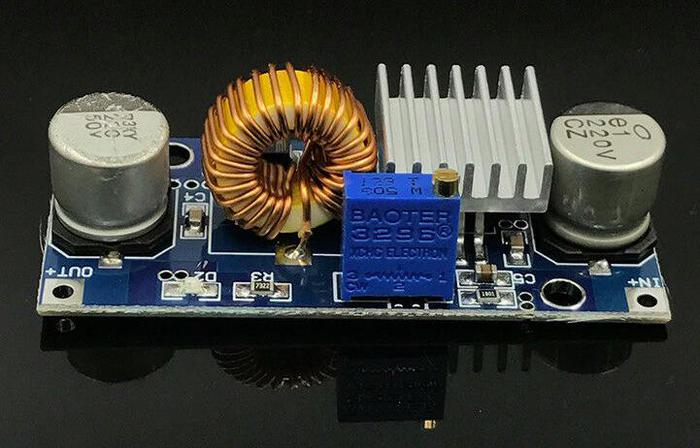

In 1949, a solution to op amp problems at low frequencies was developed: the chopper op amp.4 The idea is that a chopper modulates the input at, say 400 Hz. The op amp happily amplifies this 400-Hz AC signal. A second chopper demodulates the AC output back to DC5, providing much better performance than directly amplifying the DC signal.4 The op amp boards in the analog computer add a chopper circuit to the IC op amp to improve its performance.6

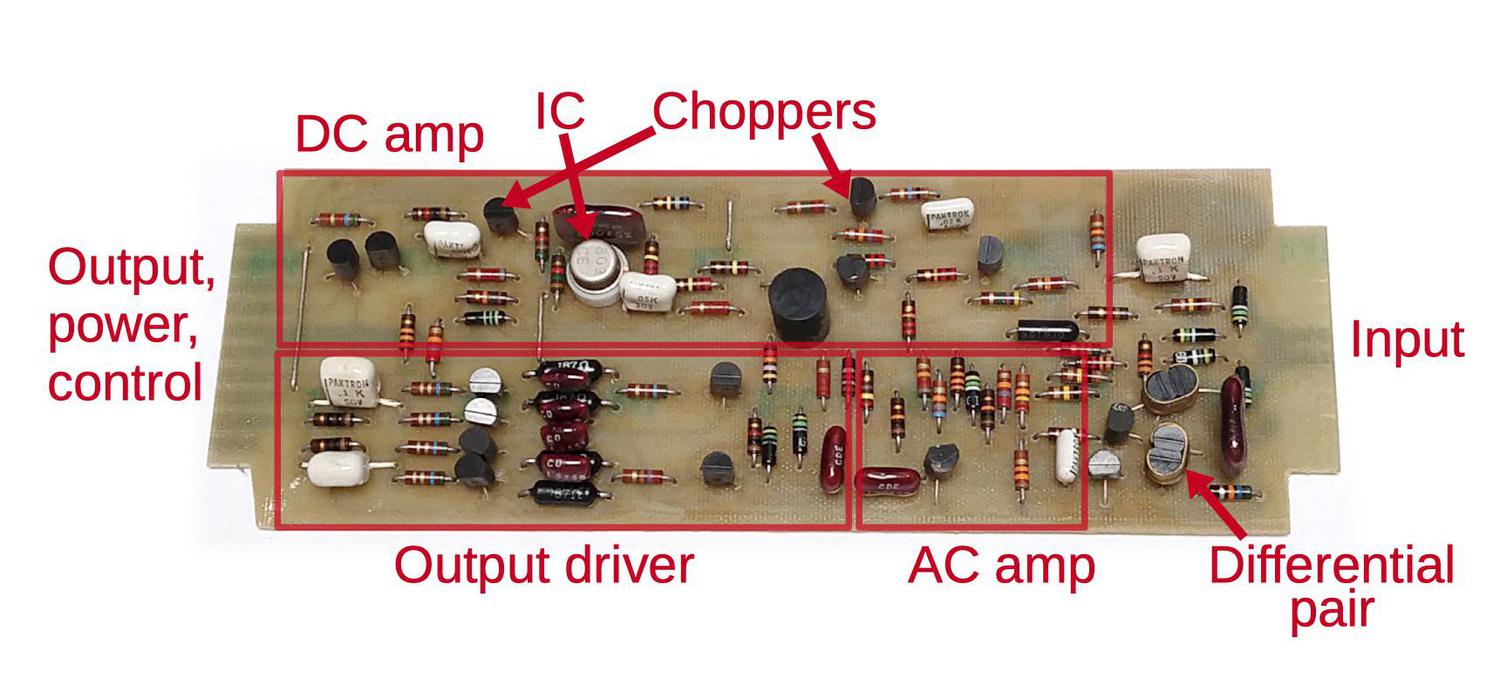

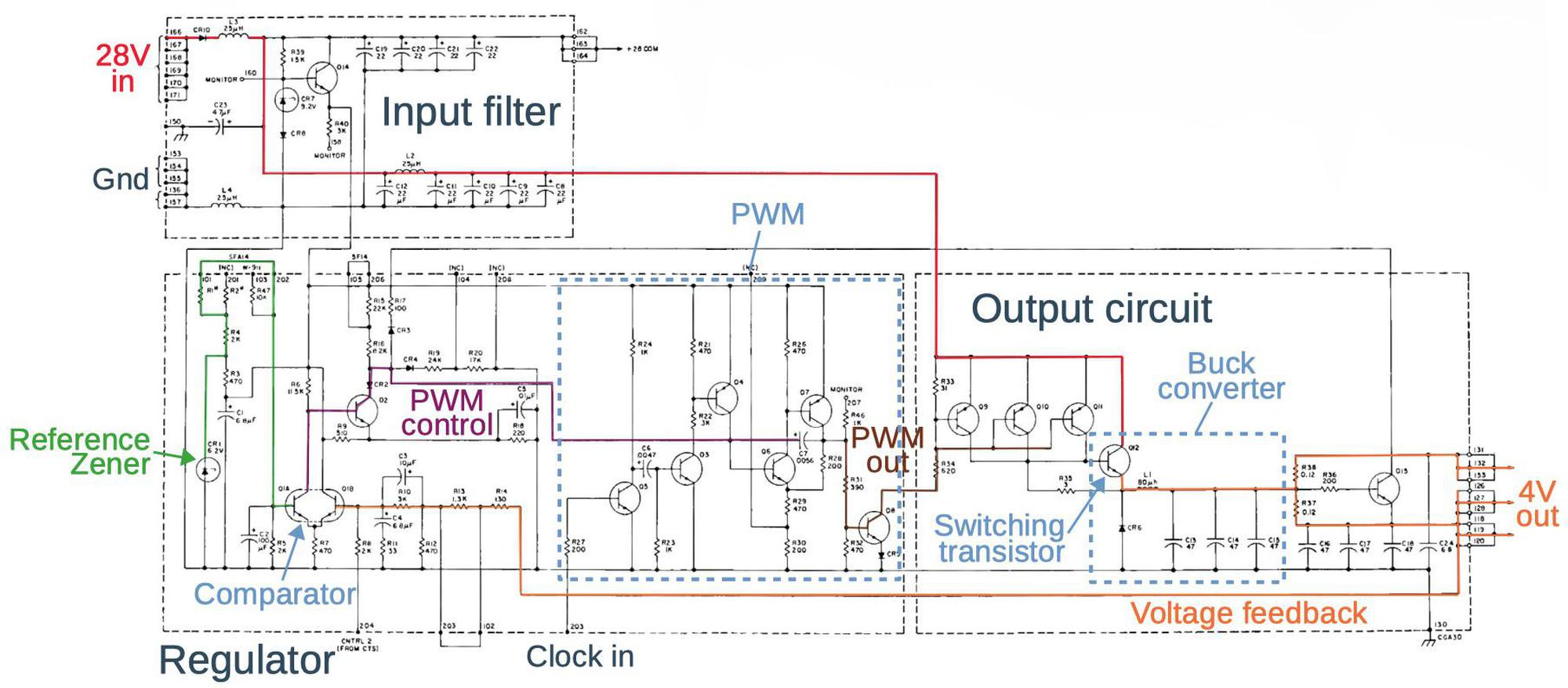

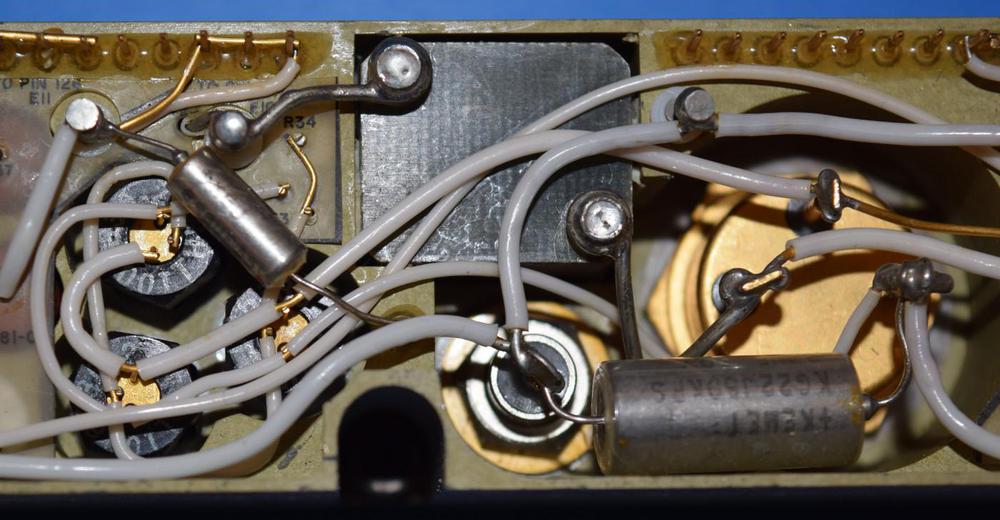

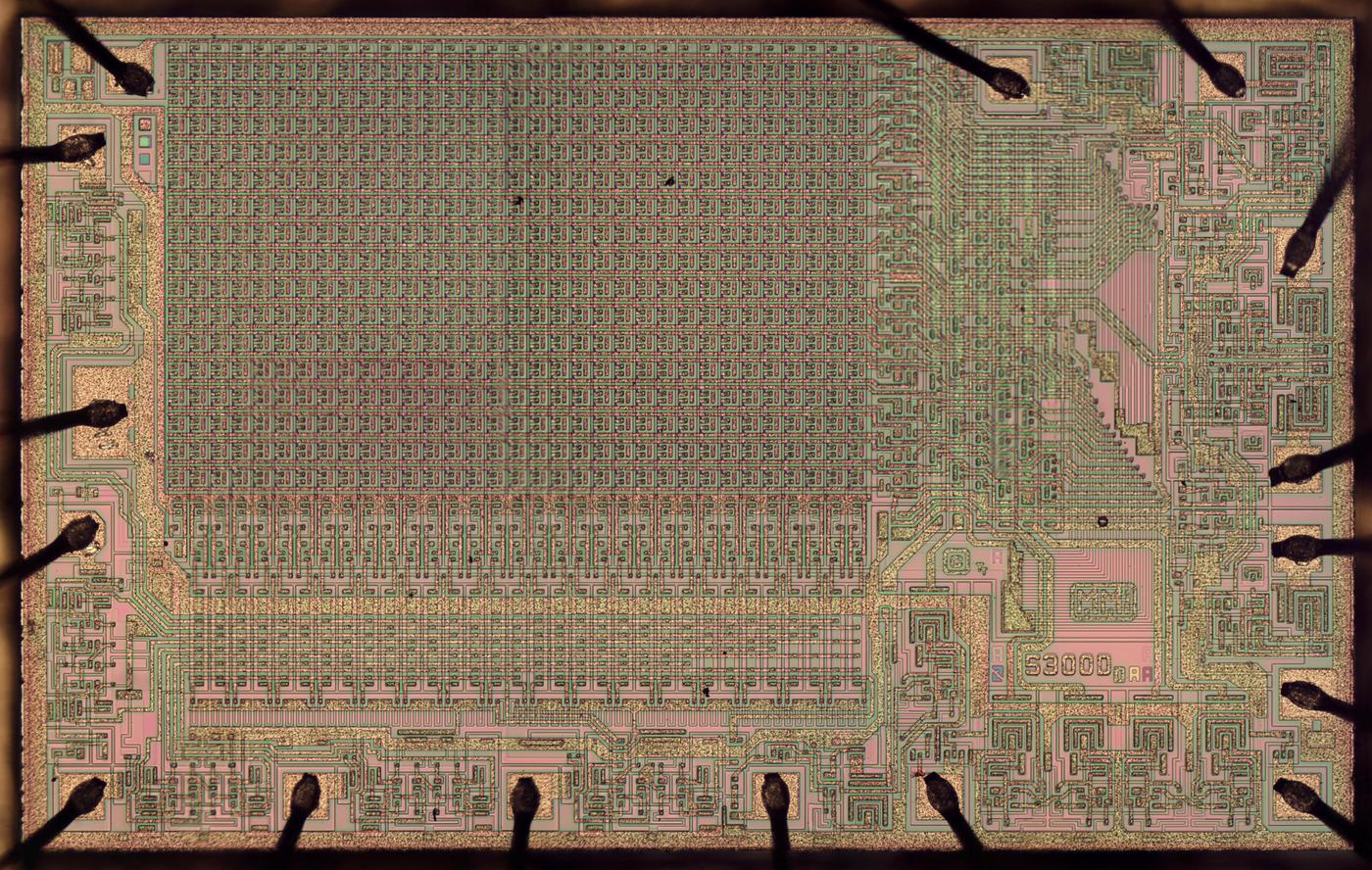

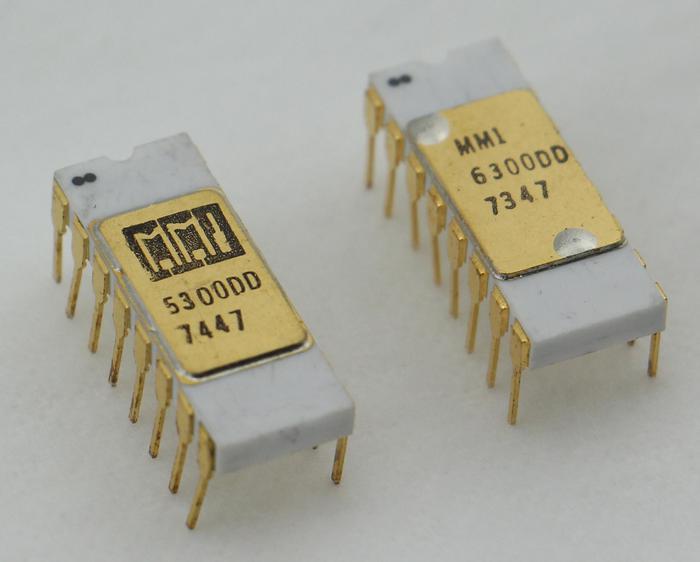

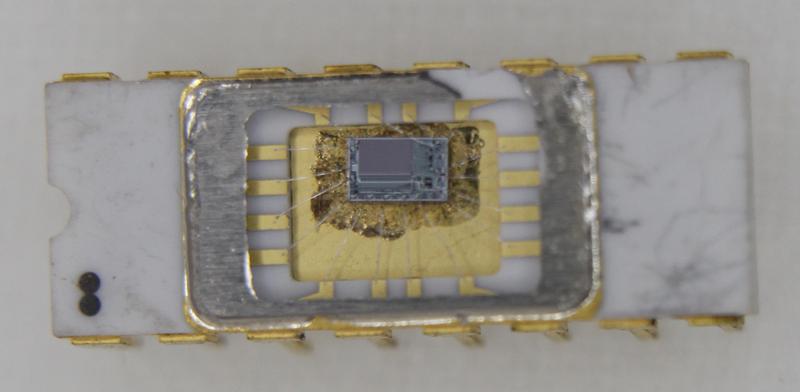

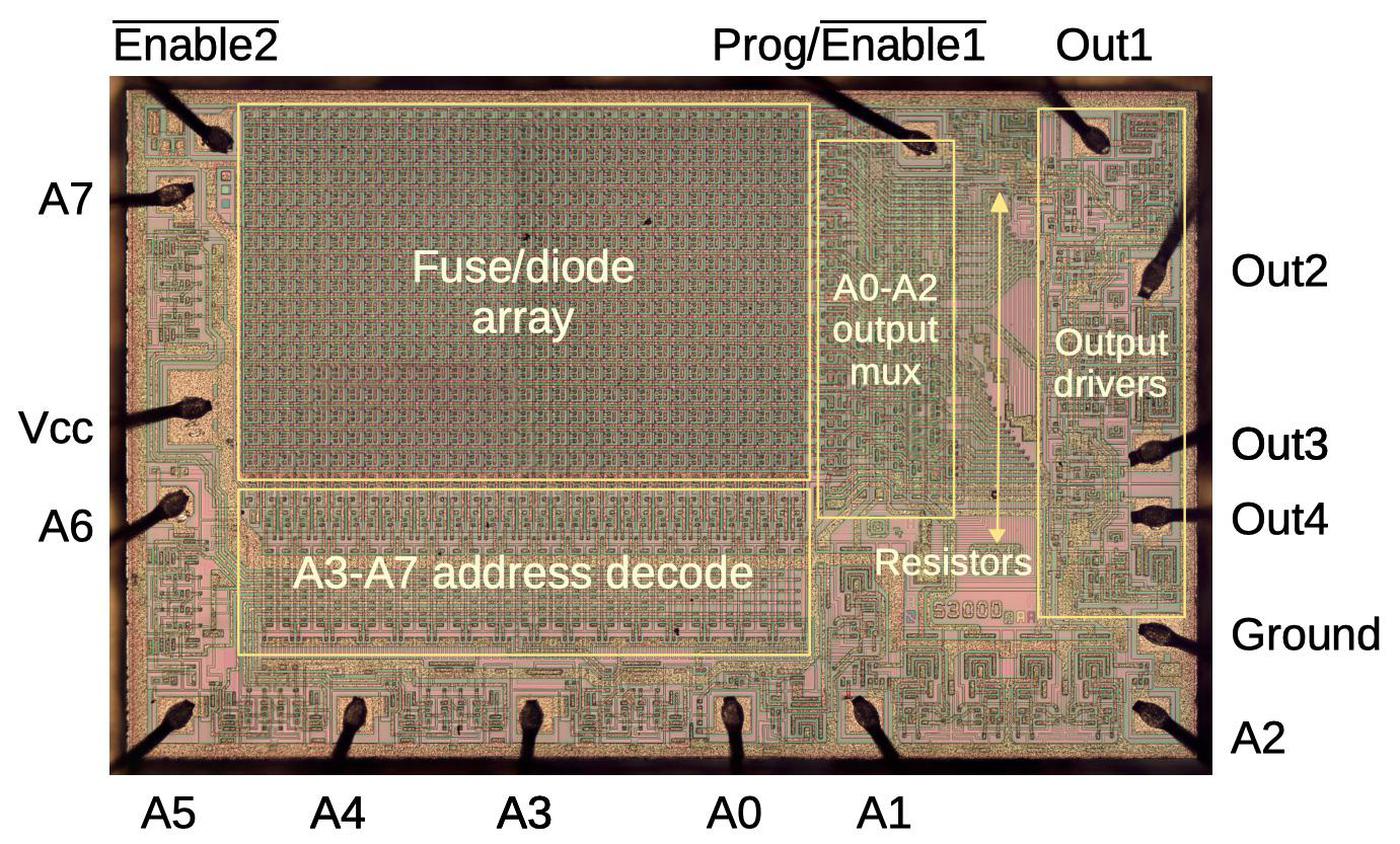

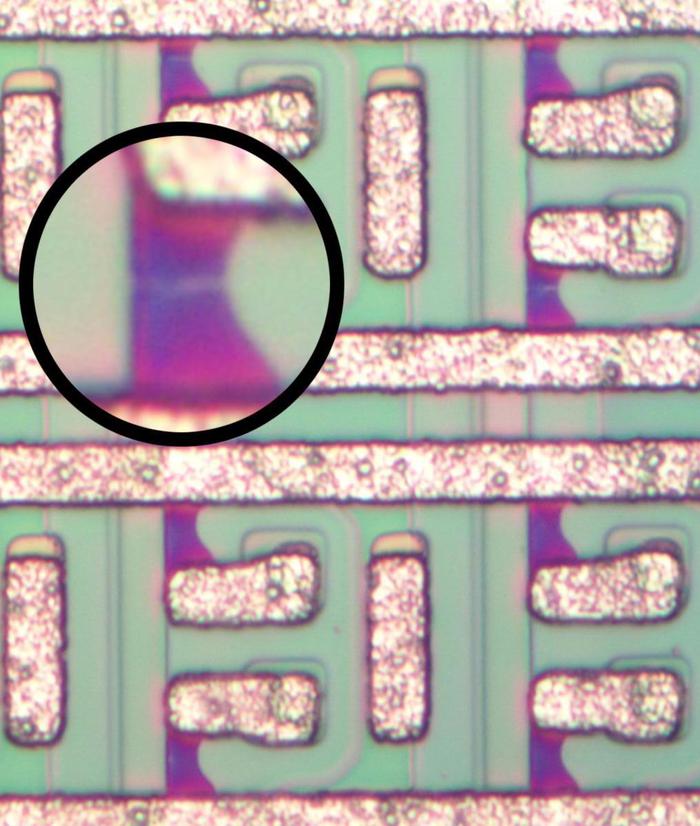

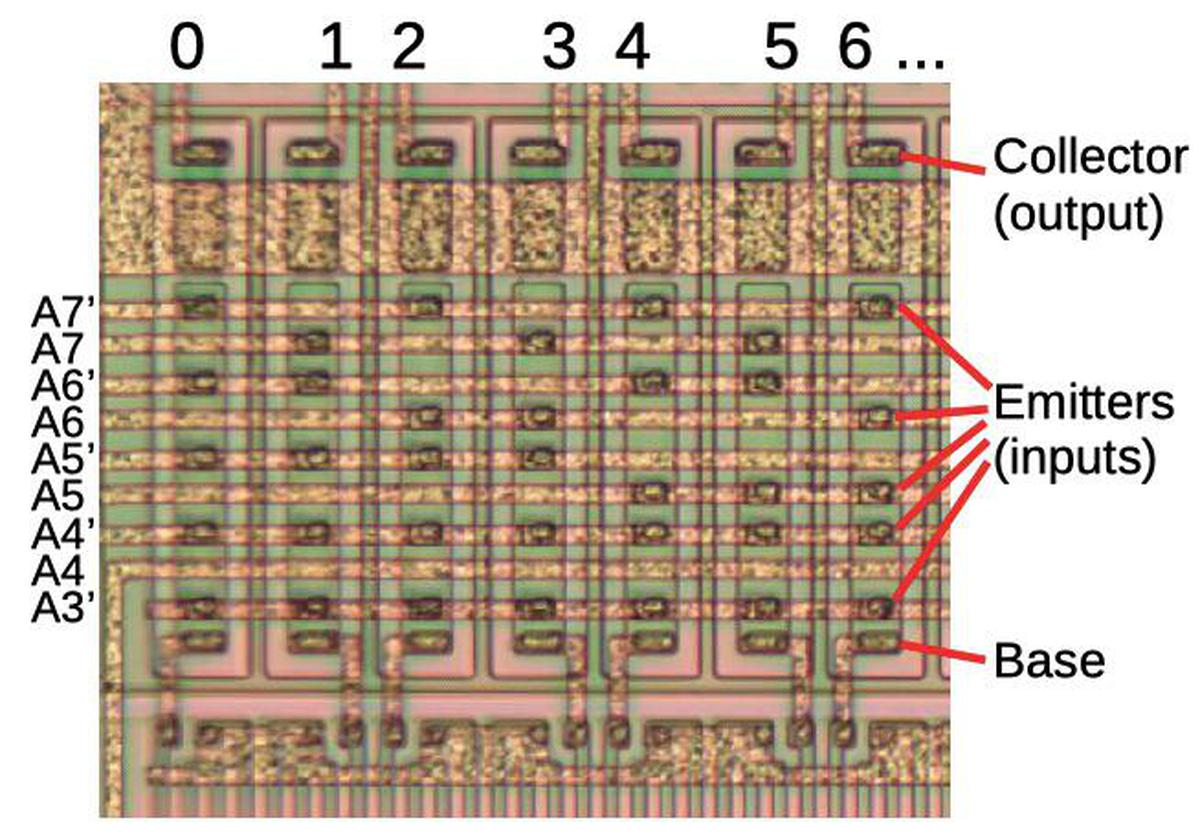

The diagram below shows one of the op amp boards.8 The op amp's single input7 is on the right (separated from all the other connections on the left, to avoid noise). The input is split into three paths. The first path is to the DC chopper amplifier. The signal goes through a low-pass filter (i.e. resistor and capacitor) to extract the DC and low-frequency signal. The chopper itself is pretty simple: a JFET transistor alternately grounds the signal as driven by an external 400 Hz oscillator. This modulated 400 Hz signal is fed to the op amp IC, an Amelco 809 high-performance op amp, introduced in 1967.9 The IC is in a round metal can; this packaging was common back then and helped shield the op amp from noise. Finally, the IC's output goes through a second chopper and filter to demodulate it.

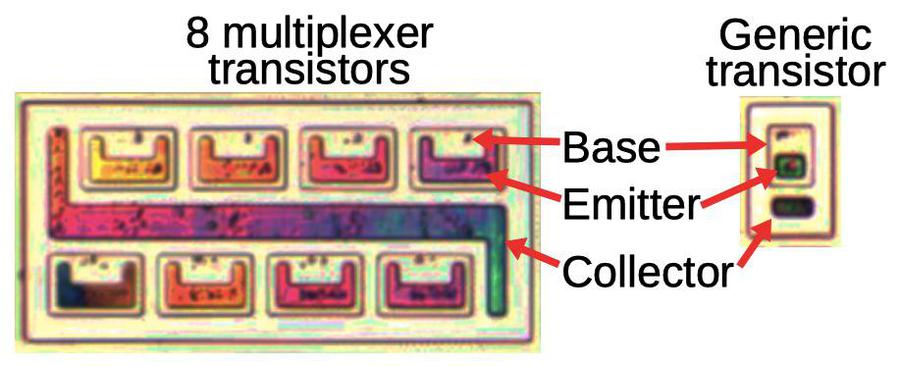

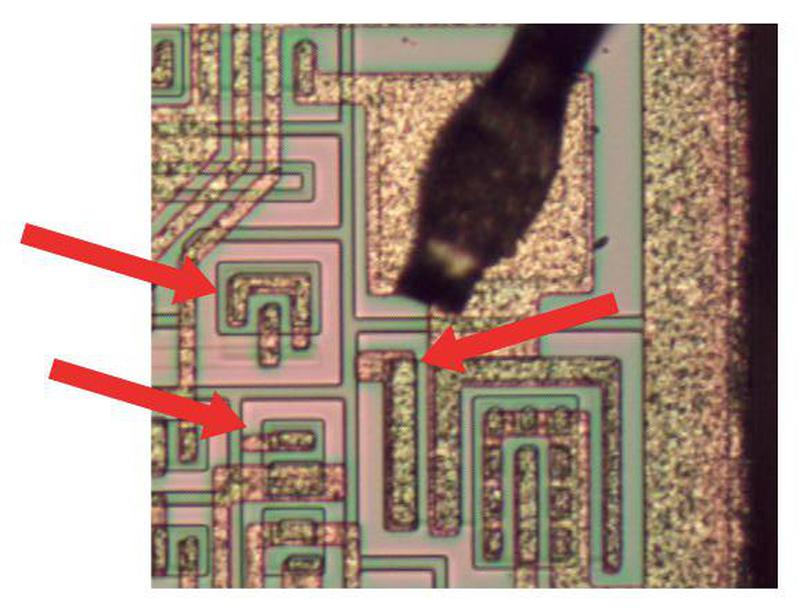

Next, the second input path is combined with the DC amplifier's output. Most op amps are based around a differential pair, and this board is no exception. In a differential pair, two transistors provide high-gain amplification of the difference between two input signals. This differential pair's inputs are the board's input and the signal from the DC chopper amp so it amplifies both the original input and the DC signal. The two transistors in the differential pair need to be exactly balanced for the op amp to function accurately. In particular, the two transistors need to be kept at the same temperature, so they are fastened together with a metal clip (below).

The third input path goes to the AC amplifier. The input goes through a high-pass filter (resistor and capacitor) and then a simple transistor buffer. This "feedforward" signal is combined with the output from the differential pair to improve the amplifier's frequency response. At this point, the input has been amplified three different ways to yield good low-frequency and high-frequency performance.

The final stage of the op amp board is an output amplifier to provide high-current output for use by the rest of the computer. This amplifier is implemented with a Class AB amplifier circuit. Individual transistors at the time weren't sufficiently powerful, so it uses two NPN transistors and two PNP transistors to drive the output.

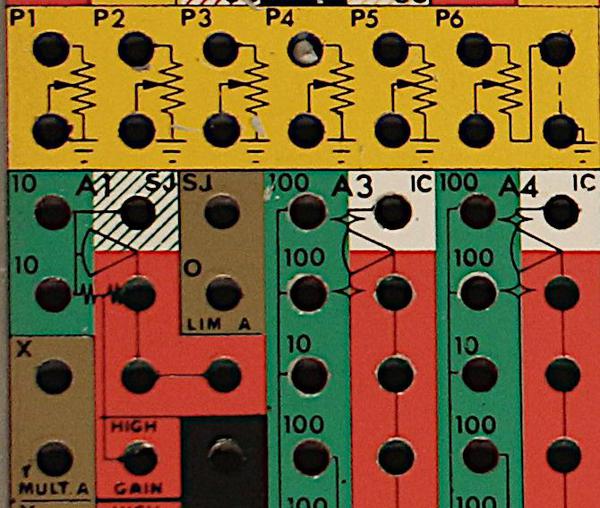

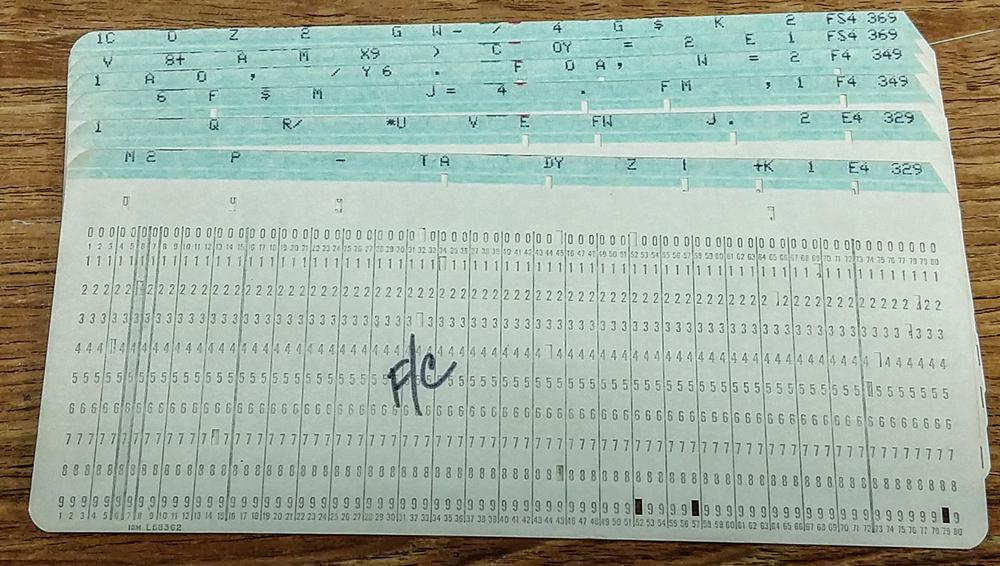

Each op amp board has its input and output wired to the patch panel. On the patch panel below, the op amps (A1 through A4) are shaped like pieces of pie; their inputs are green and outputs are red. The op amps used for integrators are also wired to the integration capacitors.

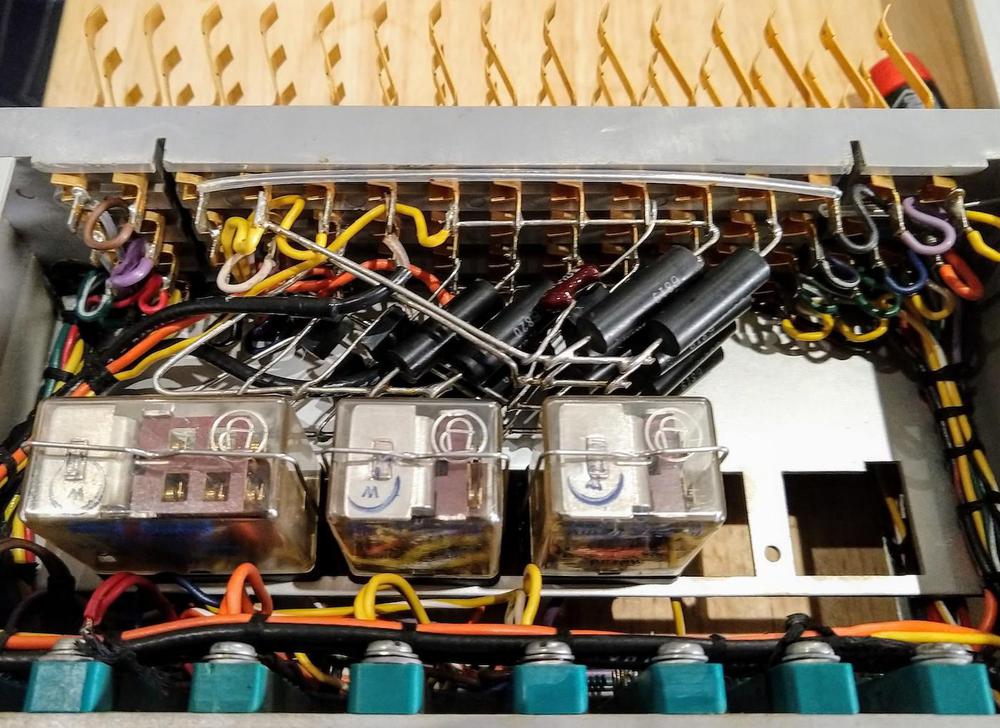

On the patch panel, each op amp has multiple input plugs with different resistor values for scaling; these are the "10" and "100" numbers above. The photo below shows these high-precision resistors (black cylinders) attached directly to the patch panel contacts. Integrator inputs are controlled by relays (below) and electronic switches so the analog computer can initialize the integration capacitors, run the computation, and then hold the result for analysis.

Conclusion

Even though op amp integrated circuits existed in the late 1960s, their performance wasn't good enough for analog computers. Instead, a whole board of components was used for a single op amp, combining the IC op amp with a chopper and other circuitry to yield a high-precision op amp. Although improvements in integrated circuits led to exponential increases in digital computer performance, analog computers received much smaller benefits from ICs. As a result, digital computers almost entirely took over and analog computers are now historical artifacts.

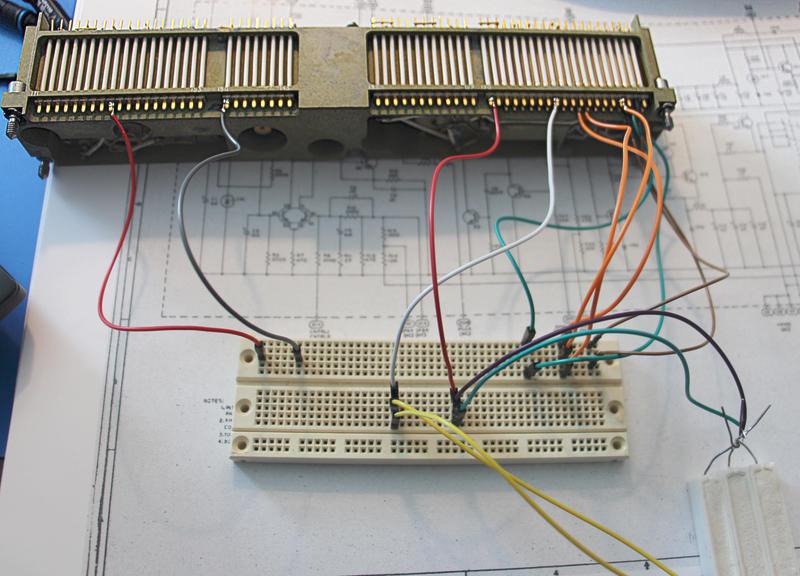

You might wonder why I'm studying the circuitry of this analog computer in such detail. The reason is that we're trying to restore the computer, but we don't have documentation.1011 Thus, I'm reverse-engineering it to determine how to restore it to operating condition and how to program it. While the circuit boards are not too complex, the computer contains many different boards to analyze. The hardest part is figuring out the connectivity of the many tightly-bundled wiring harnesses, mostly by brute-force beeping out connections with a multimeter.

You can expect more analog computer posts as we continue the restoration. Follow me on Twitter @kenshirriff to stay informed of future articles. I also have an RSS feed.

Notes and references

-

The computer's integrated circuits have 1968 and 1969 date codes on them, so I think the computer was manufactured in 1969. ↩

-

When fully populated, the computer has 6 modules behind the patch panel, but the one on the right is missing. At first, we thought the module had been lost at some point, but it appears that this computer was a lower-cost model and was never fully populated. Evidence of this is that 1/4 of the potentiometers above the patch panel are not installed; these potentiometers would be handled by the missing module. ↩

-

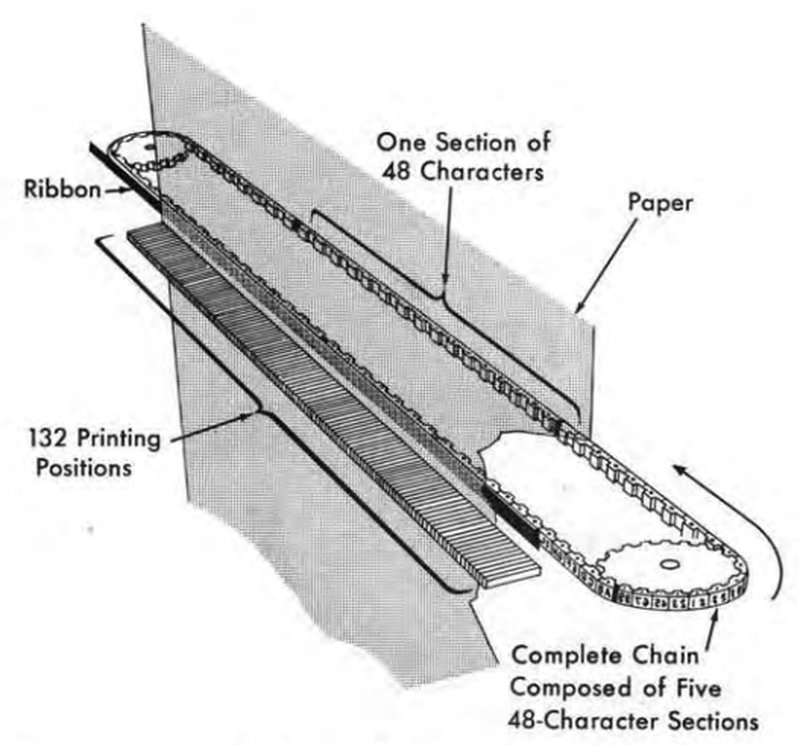

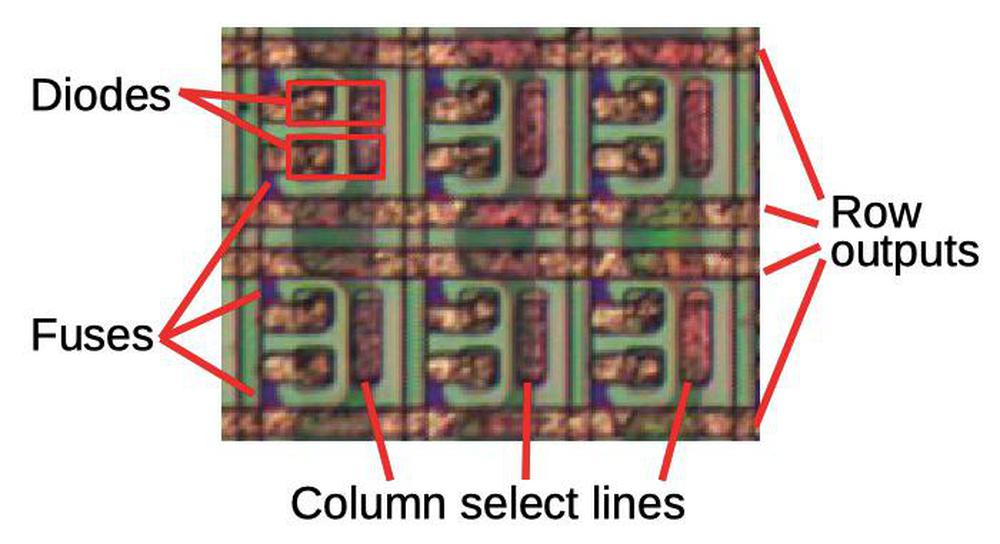

Analog computers could implement arbitrary functions using diode-resistor networks. (Each diode turned on at a particular input voltage level, and contributed a ramp to the output.) For multiplication, diode-resistor networks were configured to implement a parabolic function (i.e. squaring). Multiplication was implemented through the identity X×Y = ((X+Y)2 - (X-Y)2)/4. The sum and difference were computed using op amps, while squaring was done with the parabolic function generator. ↩

-

Modern chopper op amps use a more complex chopper-stabilizing mechanism, with two op amps. A secondary op amp uses the chopped signal to null out the main op amp. This tutorial discusses the difference between the classic and modern chopper op amps; there's also a discussion here. The point of this footnote is to avoid confusion between the design of chopper op amps used in the analog computer and modern chopper designs. ↩

-

You can sort of think of the chopper as performing amplitude modulation on the signal, like an AM radio signal. However, the demodulation needs to be "phase-sensitive" so it can tell the difference between a positive input and a negative input. This is in contrast to AM-radio demodulation, which can be done with a diode since phase doesn't matter. ↩

-

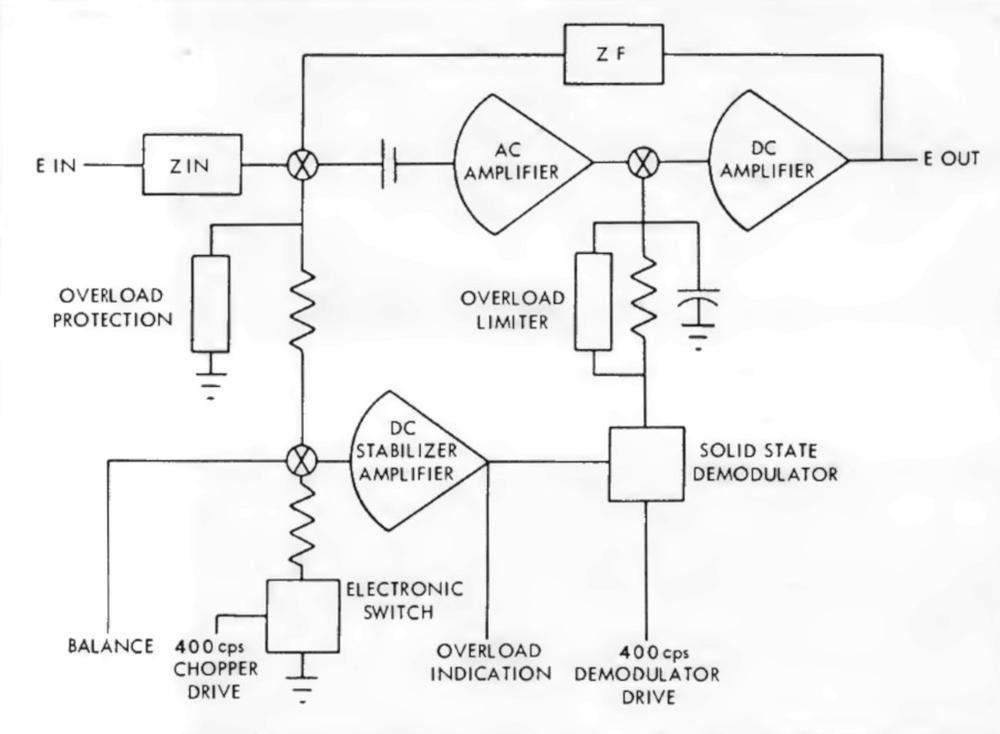

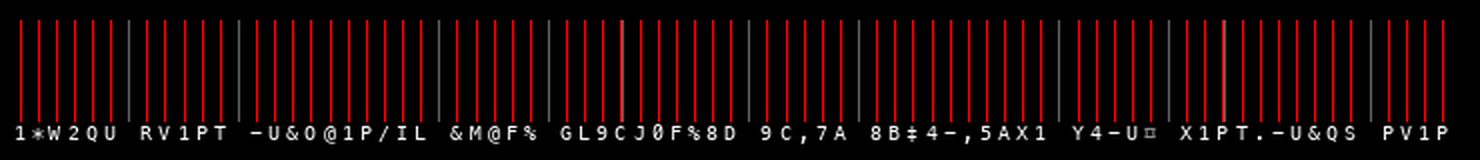

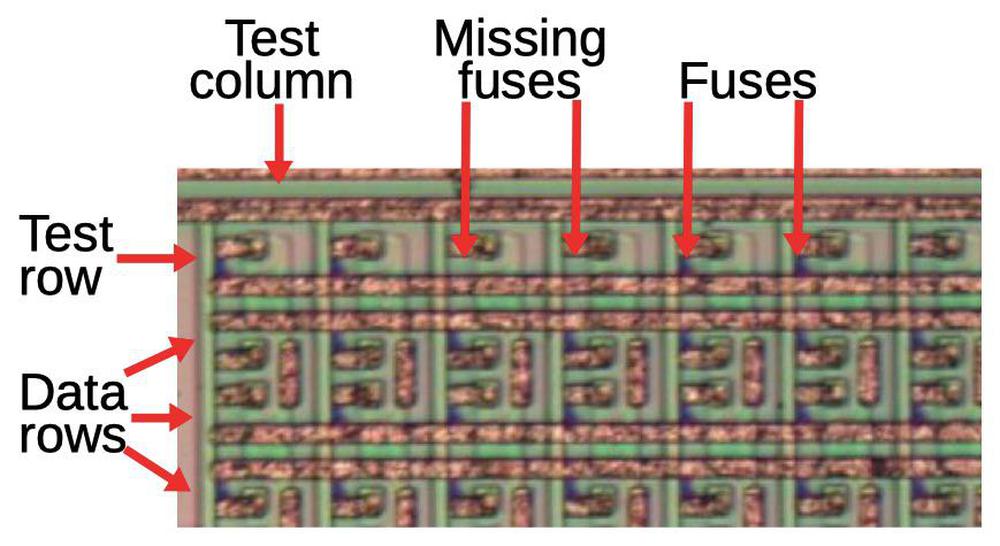

The diagram below (from the brochure) shows the structure of the op amp board. The basic idea is that part of the input goes through a capacitor (i.e. high-pass filter) into the AC amplifier. The input also goes into the "DC stabilizer amplifier", which has a chopper on its input. The output is demodulated and put through a low-pass filter (resistor/capacitor). The two amplifier outputs are combined and fed into the "DC amplifier", the output amplifier.

Simplified schematic of the op amp.Note the circuitry for overload detection and protection. In an analog computer, overload can easily happen if any of the values get higher than expected and exceed the op amp limits (+/- 10 volts). This is bad because it will cause the results to be wrong. The op amp detects overload and illuminates a panel light so the user knows there is a problem. An important part of analog computer programming is how to scale everything so the mathematical values fit within the physical limits of the system. ↩

-

Nowadays, op amps have a positive and negative input. In analog computers, however, op amps usually had just the negative input. Thus, they summed and inverted their inputs. ↩

-

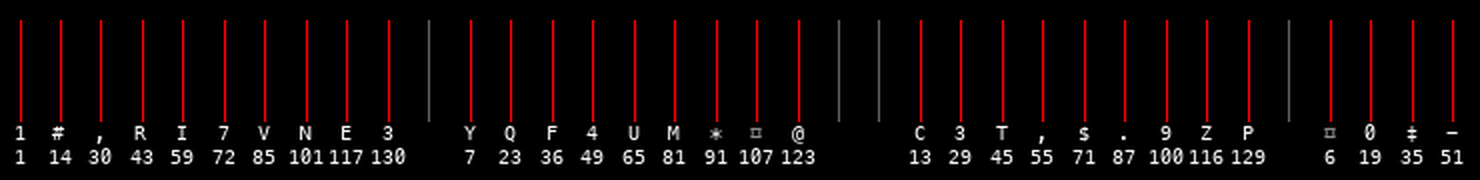

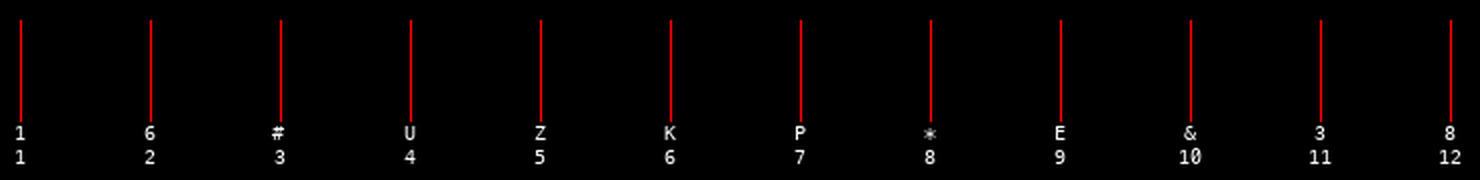

For reference, I've reverse-engineered the pinout of the op amp board. The input is two shorted pins on the right. The pins along the left of the board (with their connector label) are:

L: balance in

K: chopper ground

J: overload signal out

H: chopper drive in

F: ground

E: ground

D: -15V

C: +15V

B: op amp output

A: unused ↩ -

Although now almost forgotten, Amelco was an important semiconductor company producing high-performance op amps. Among other things, Amelco made the first JFET op amp. It was founded by Hoerni (who invented the "planar process" for ICs at Fairchild). I reverse-engineered a hybrid Amelco op amp and discuss the history of Amelco in this article. The Amelco 809C op amp datasheet can be found here. ↩

-

As far as documentation on this computer, archive.org has a Simulators Inc 240 brochure scanned from "Ted Nelson's Junk Mail". The Analog Computer Museum has a brochure in German for the Dornier 240, an almost identical computer. (I haven't been able to find out the relationship between Simulators Inc and Dornier, but presumably one company licensed it from the other.) ↩

-

If you're looking for books on analog computers, here are my comments on ones I've read recently:

Analog computer programming is a modern book on analog computers, and a good place to start.

Introduction to analog computer programming is a reasonable introduction; the PDF is online.

Analog and analog/hybrid computer programming comprehensively explains how to solve many different types of problems.

Electronic analog and hybrid computers has a detailed discussion of the hardware implementations of analog computers of this era.

Analog and hybrid computing provides a basic description of analog computers and their programming.

Analog computer techniques is hard to follow and from the vacuum tube era, so I don't recommend it. ↩