The animation below shows how the hammers (green) interact with the chain (blue) as the chain slowly moves to the left. When a hammer is aligned with a chain element and can print the character, the elements turn red. The numbers above the hammers show the hammer number from 1 to 132. The numbers below the chain show the chain element number. Below that is the character printed by each chain element.

Each step of the animation corresponds to 11.1 microseconds of real time during which the chain moves 0.001 inches. The slow setting is a million times slower than real life, while the fast setting is 3000 times slower than real life. Printing a line requires 48 scans in total.

(Click Slow to slow down the animation.)

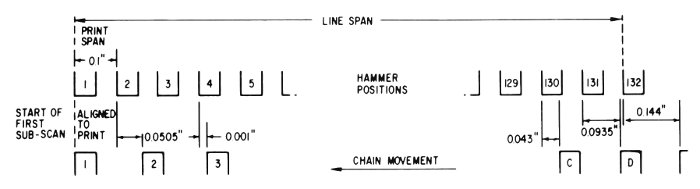

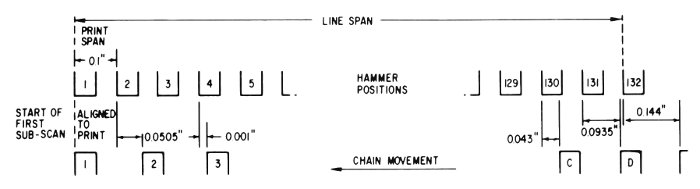

The timing between the hammers and the rotating chain is tricky to understand. The spacing between the chain and the hammers is very slightly (0.001 inches) more than a 3:2 ratio, so a tiny movement of the chain changes the aligned elements. One hammer at a time is aligned with a type element, giving it the option to fire and print a character. As the chain moves, a new hammer and type element are aligned. Due to the spacing, every third hammer will line up with every second type element in sequence. After 44 (one third) of the hammers have lined up, one print subscan is completed. Three print subscans give each hammer a chance to print a character, forming a print scan. Since there are 48 characters, 48 print scans are required to print a full line. The chain moves very fast (90.3 inches per second) and a full line requires just 80 milliseconds to print.

The following diagram from IBM's Early Computers (figure 12.4) shows the dimensions and alignment of the hammer and chain.

To see the same simulation for the faster IBM 1403 N1 printer, click here.