Introduced in 1978, the revolutionary Intel 8086 microprocessor led to the x86 processors used in most desktop and server computing today. This chip is built from digital circuits, as you would expect. However, it also has analog circuits: charge pumps that turn the 8086's 5-volt supply into a negative voltage to improve performance.1 I've been reverse-engineering the 8086 from die photos, and in this post I discuss the construction of these charge pumps and how they work.

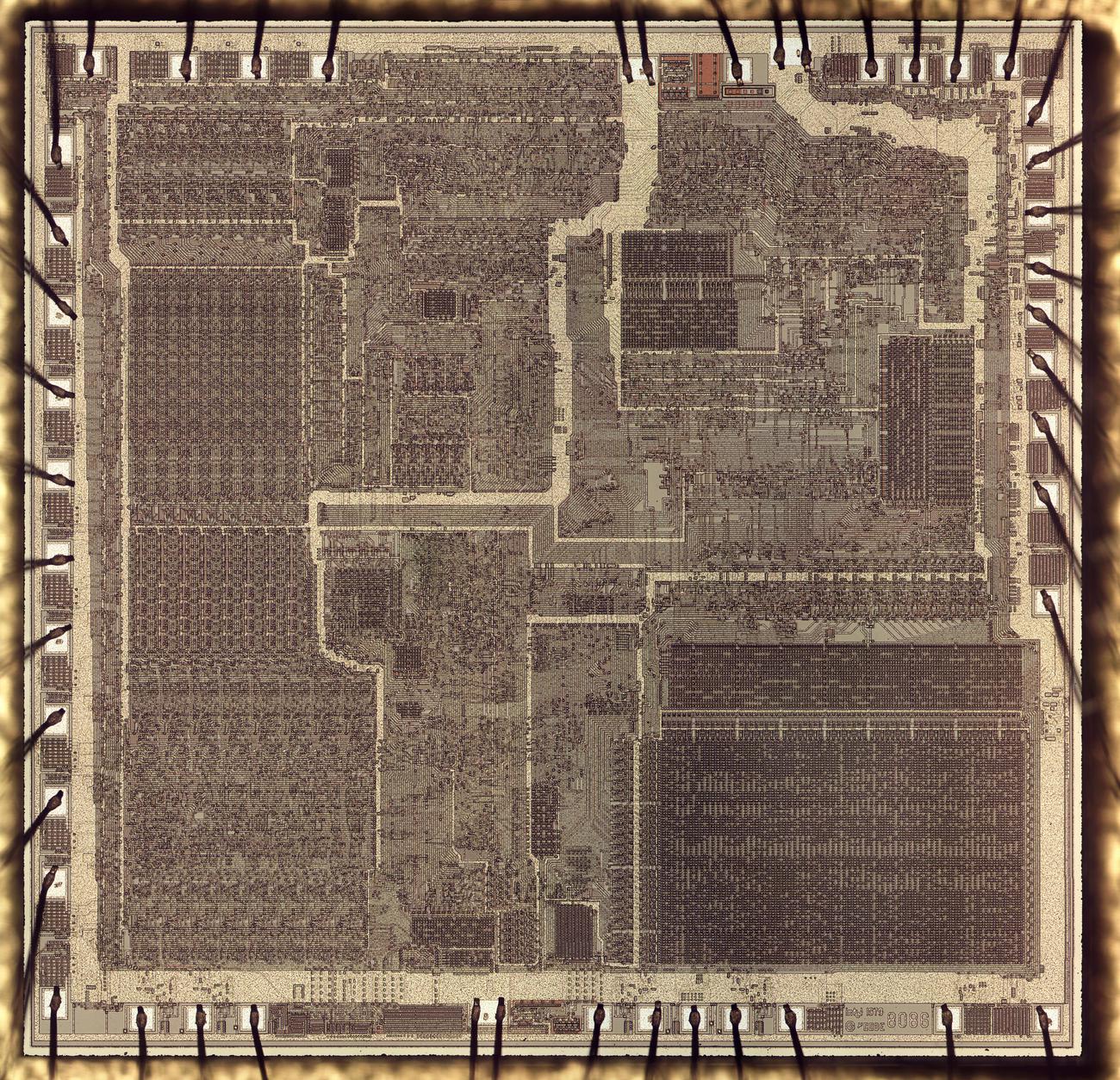

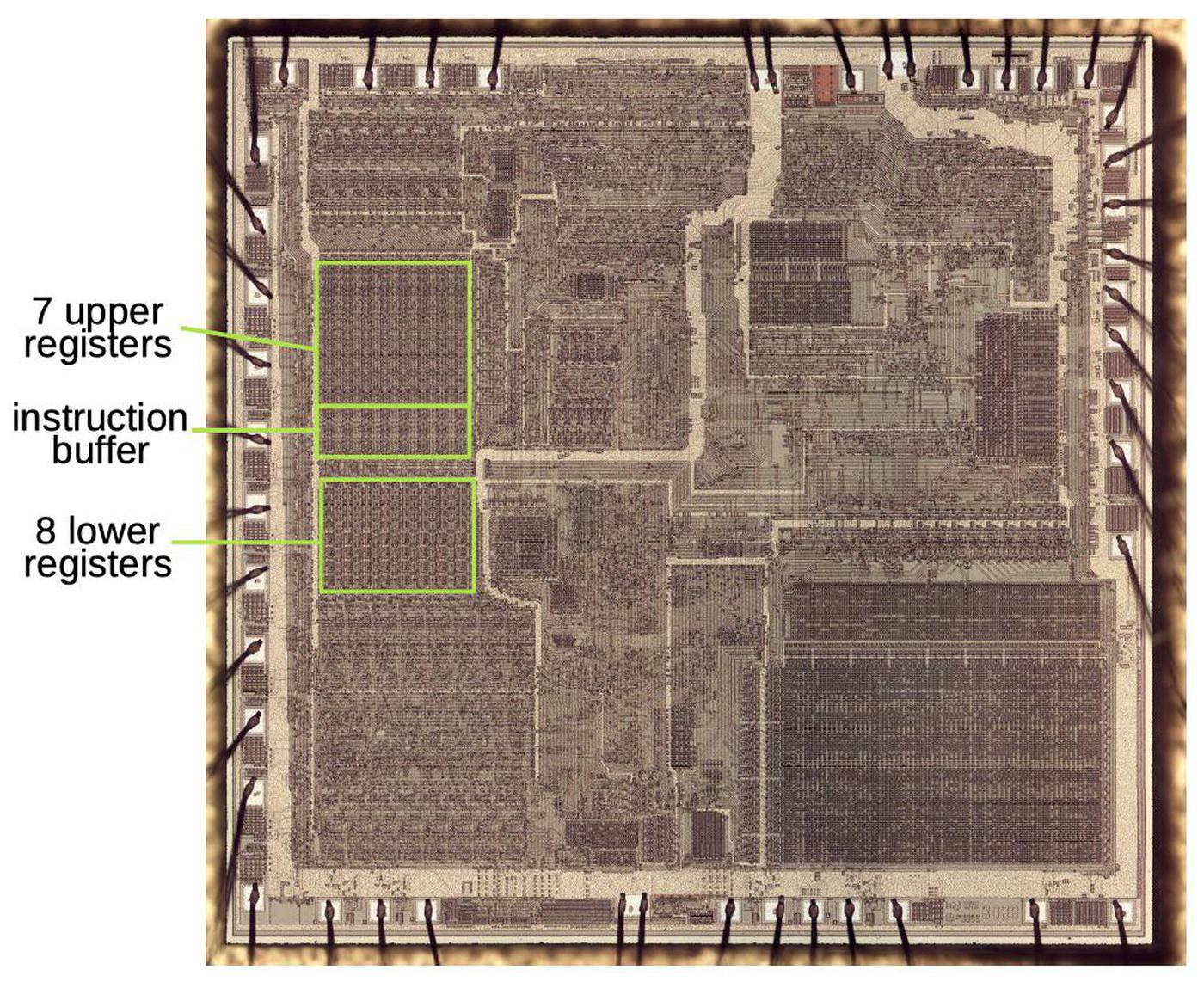

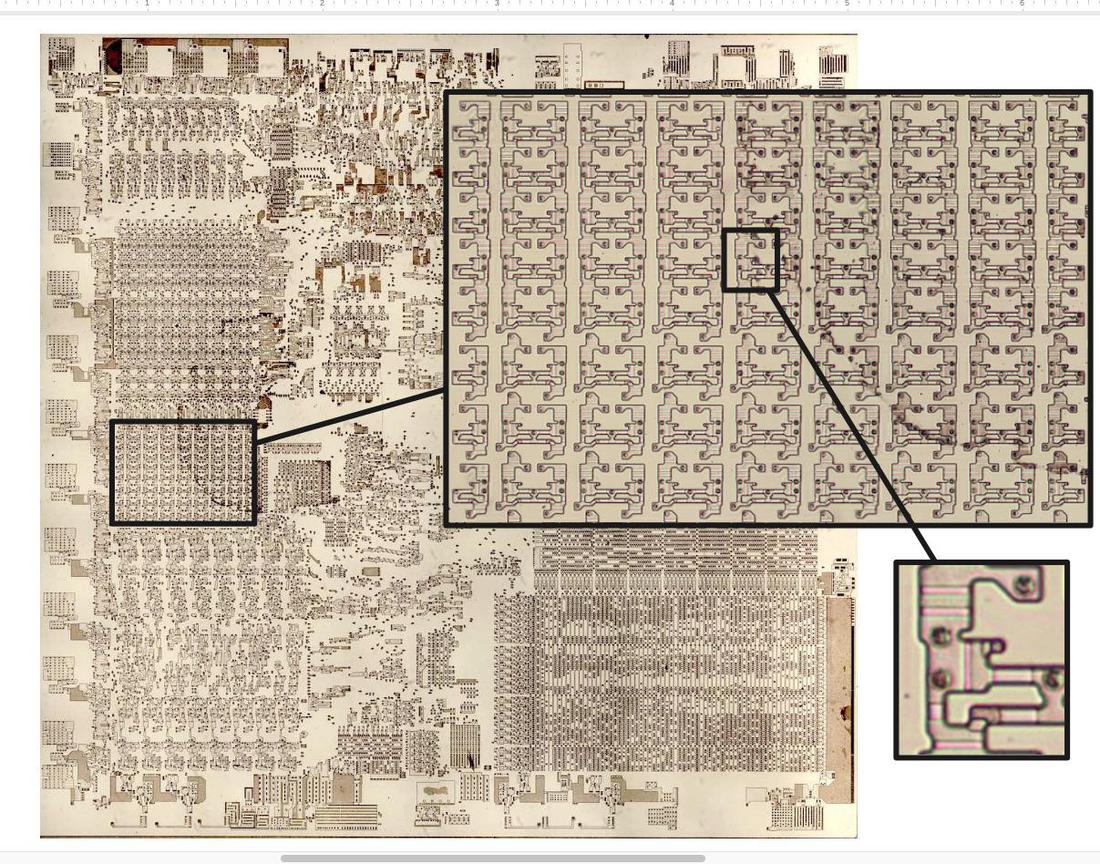

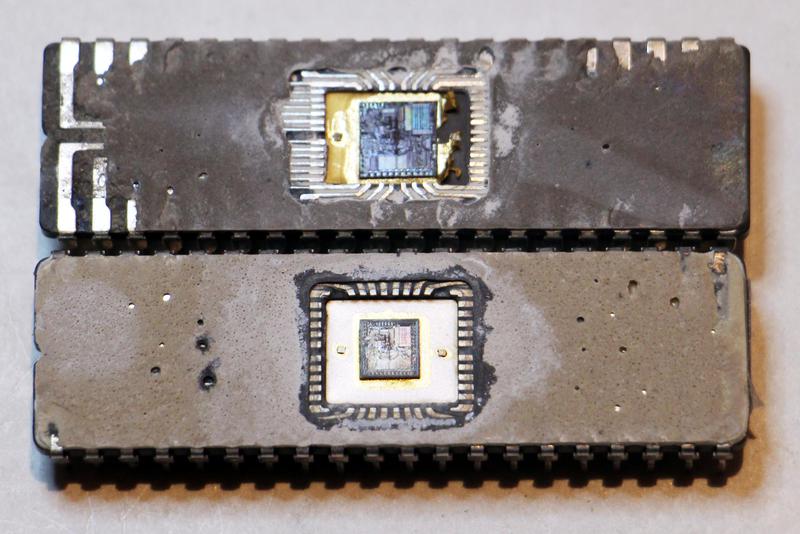

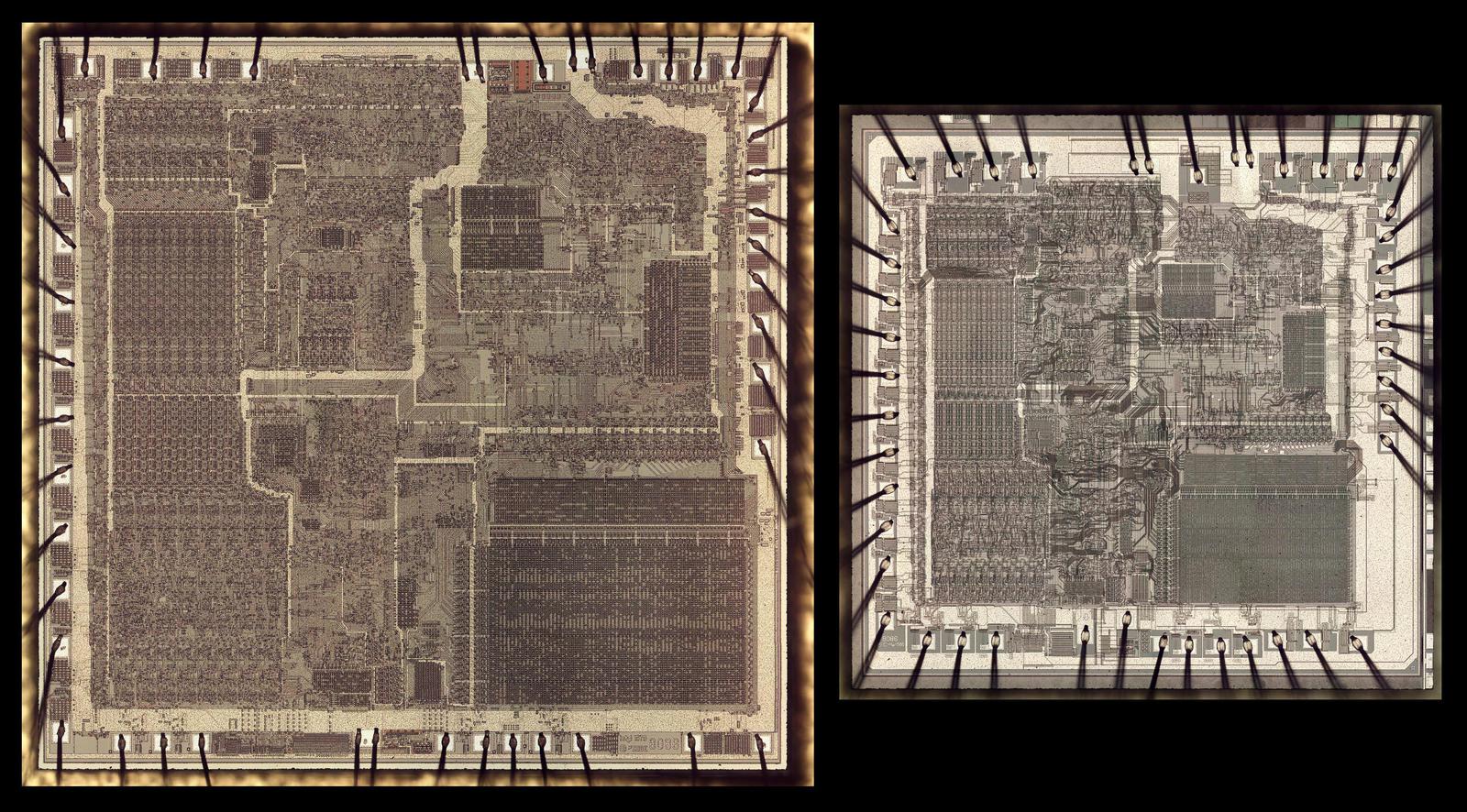

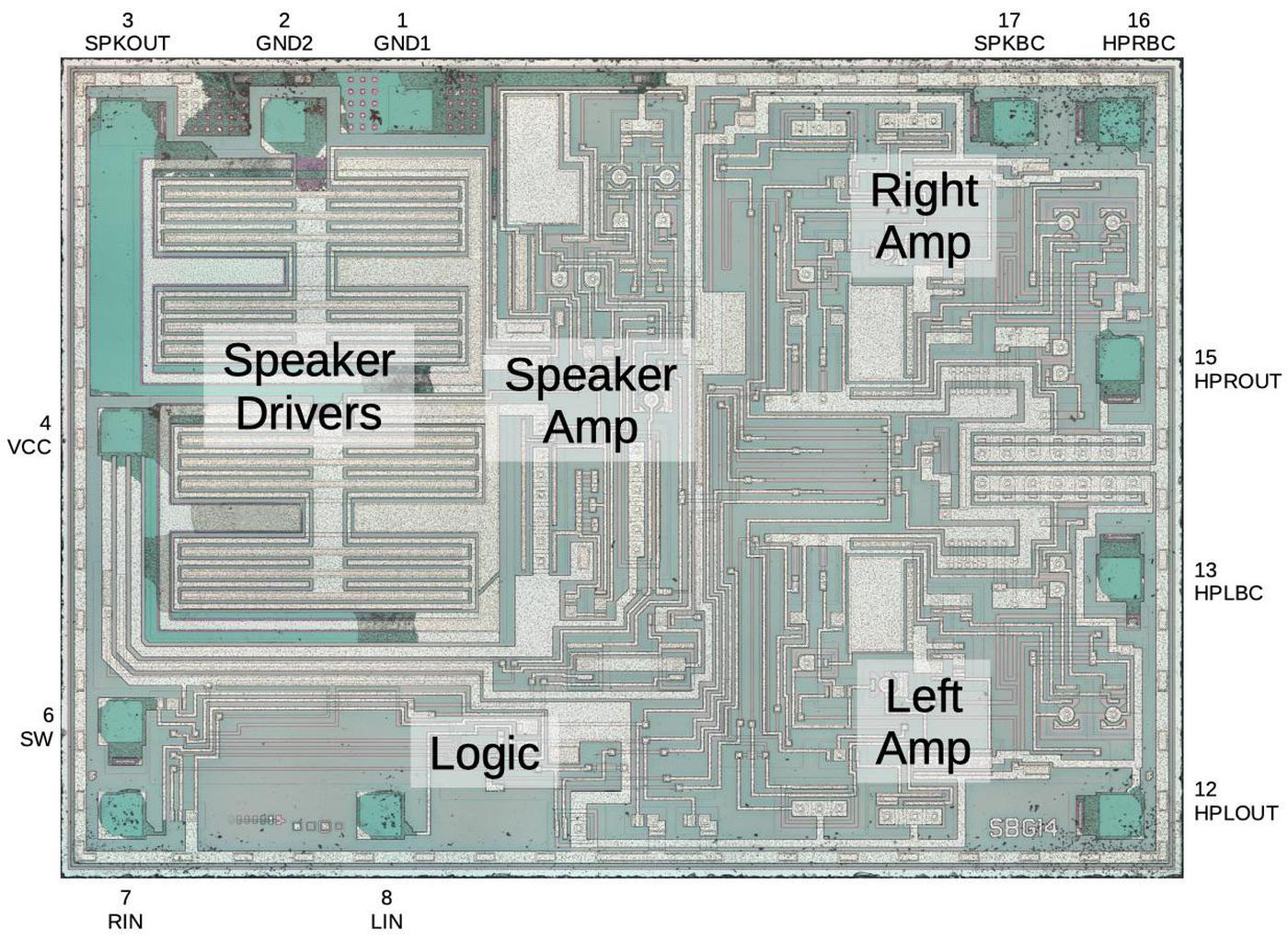

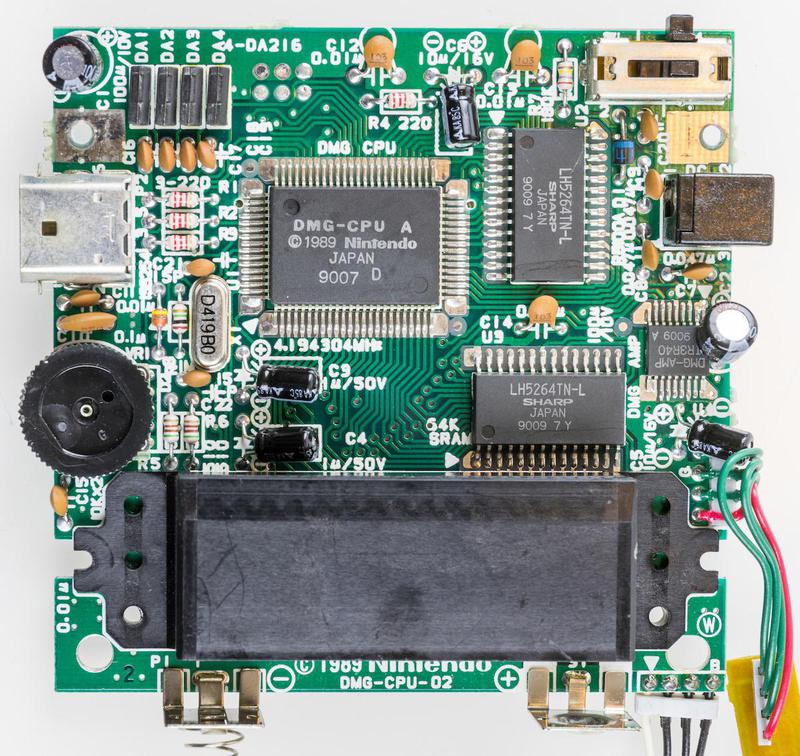

The photo above shows the tiny silicon die of the 8086 processor under a microscope. The metal layer on top of the chip is visible, with the silicon hidden underneath. Around the outside edge, bond wires connect pads on the die to the chip's 40 external pins. However, careful examination shows that the die has 42 bond pads, not 40. Why are there two extra ones?

An integrated circuit starts with a silicon substrate, and transistors are built on this. For high-performance integrated circuits, it is beneficial to apply a negative "bias" voltage to the substrate. 2 To obtain this substrate bias voltage, many chips in the 1970s had an external pin that was connected to -5V,3 but this additional power supply was inconvenient for the engineers using these chips. By the end of the 1970s, however, on-chip "charge pump" circuits were designed that generated the negative voltage internally. These chips used a single convenient +5V supply, making engineers happier.

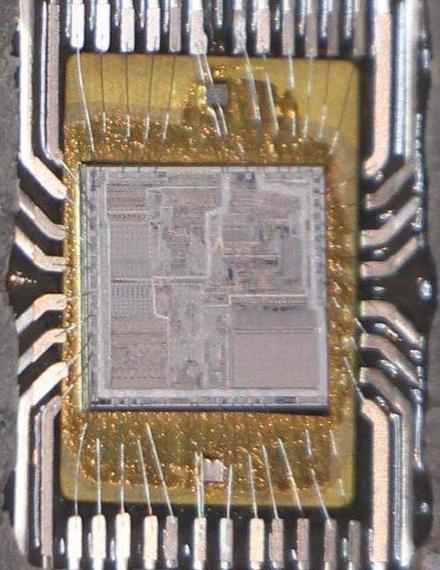

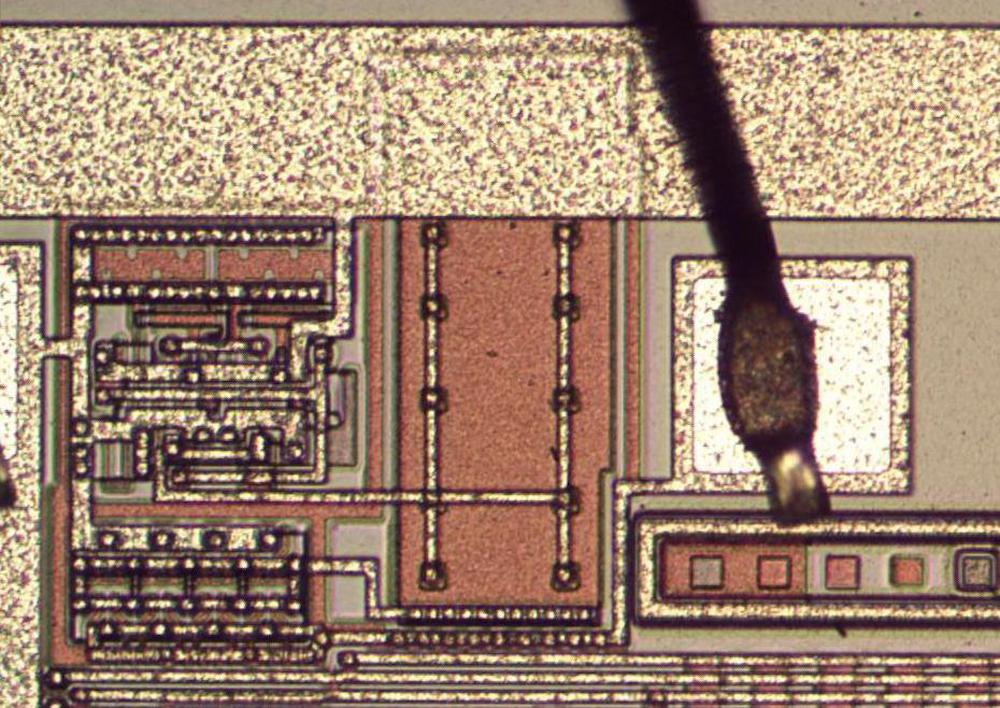

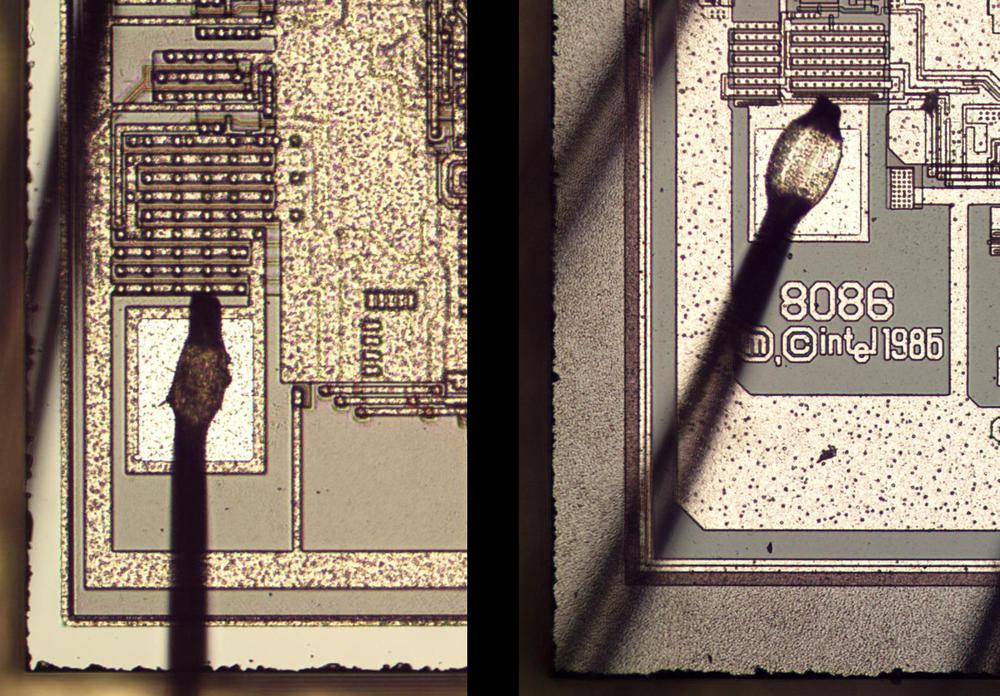

On the 8086 die, the two extra pads feed this negative bias voltage to the substrate. The photo above shows the silicon die as mounted in the chip, with bond wires connected to the lead frame that forms the pins. Looking carefully, there are two small gray squares above and below the die; each connected to one of the "extra" bond pads. The charge pumps on the 8086 die generate a negative voltage, which passes through the bond wires to these squares, and then through the metal plate underneath to the 8086's substrate.

How the charge pumps work

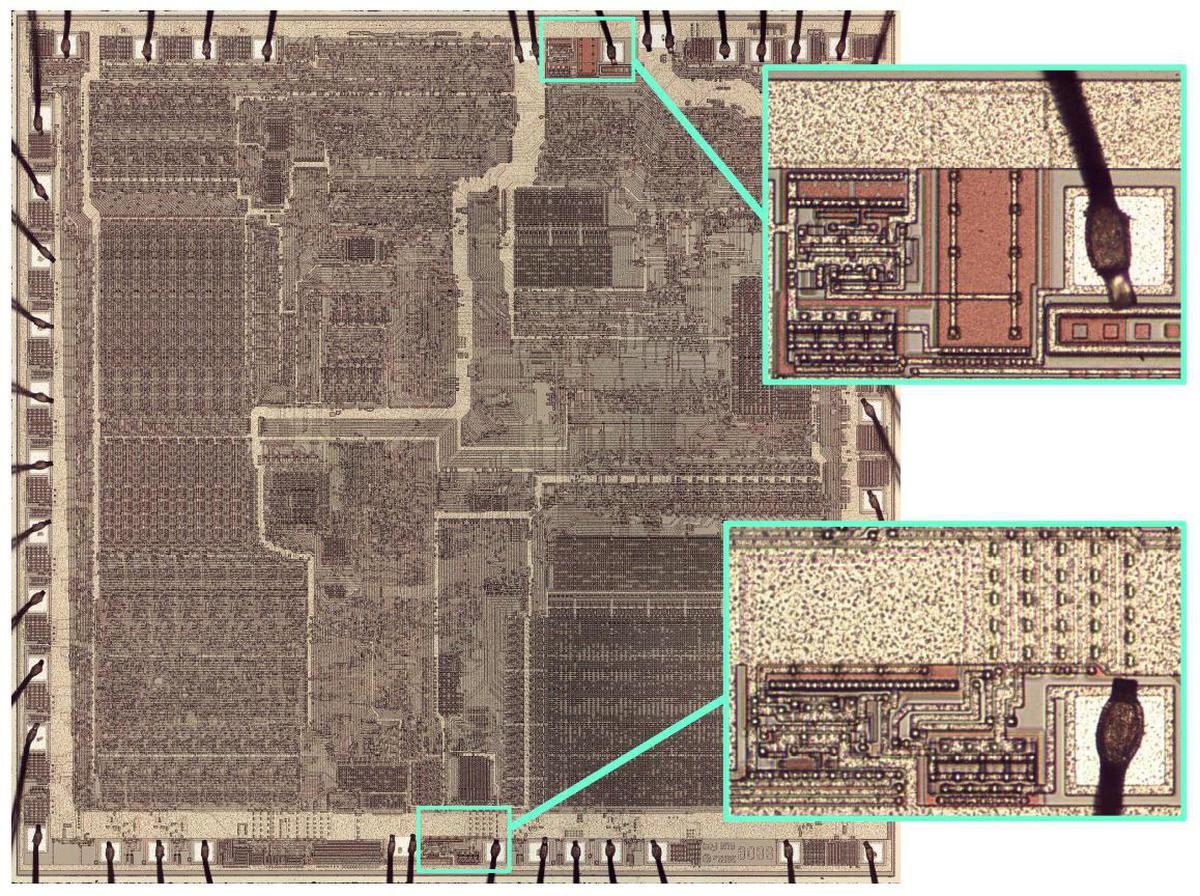

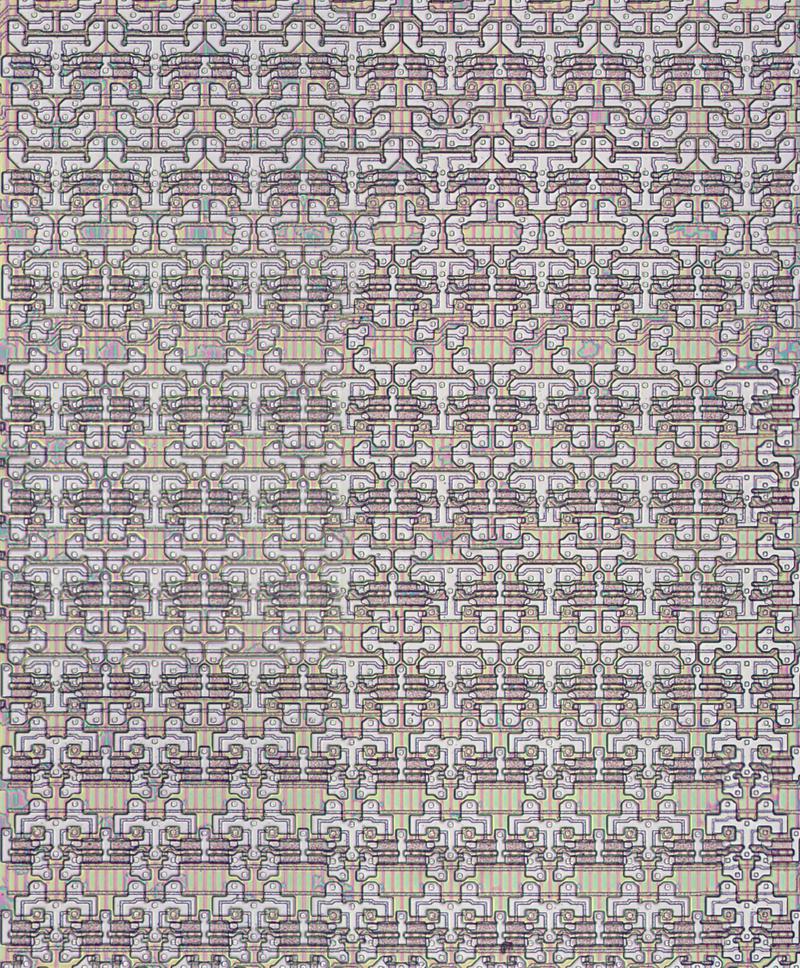

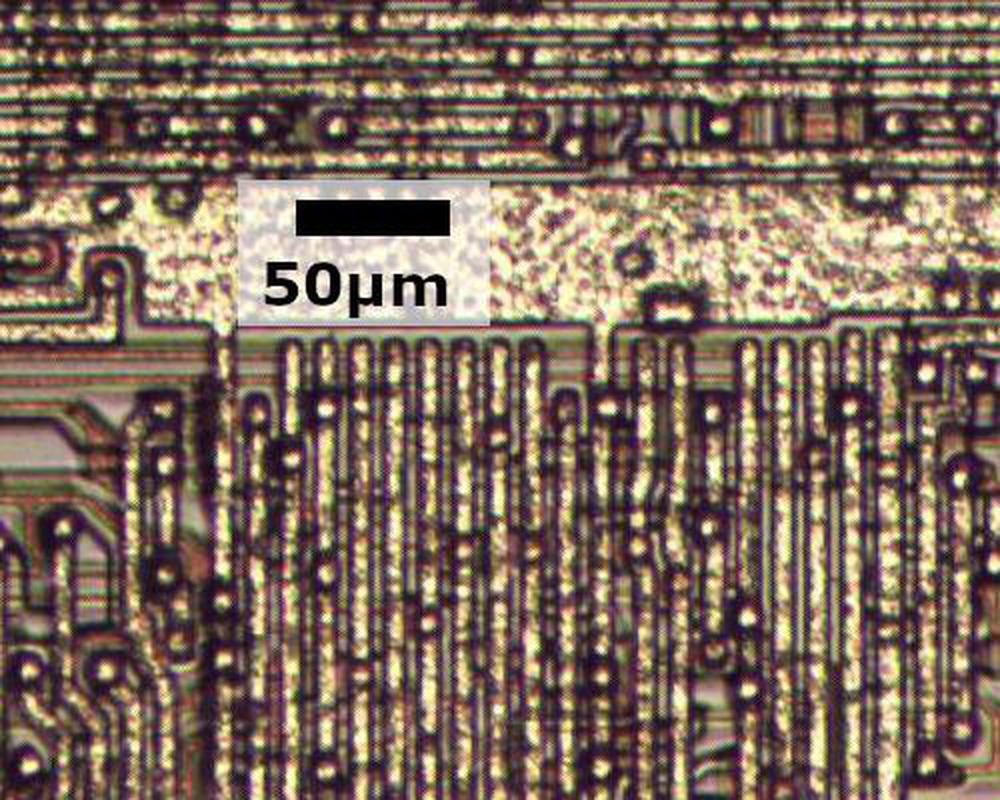

The photo below highlights the two charge pumps in the 8086. I'll discuss the top one; the bottom one has the same circuitry but a different layout to fit in the available space. Each pump has driver circuitry, a large capacitor, and a pad with the bond wire to the substrate. Each pump is located next to one of the 8086's two ground pads, presumably to minimize electrical noise.

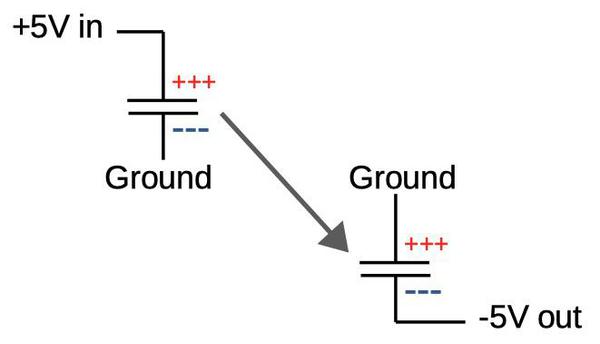

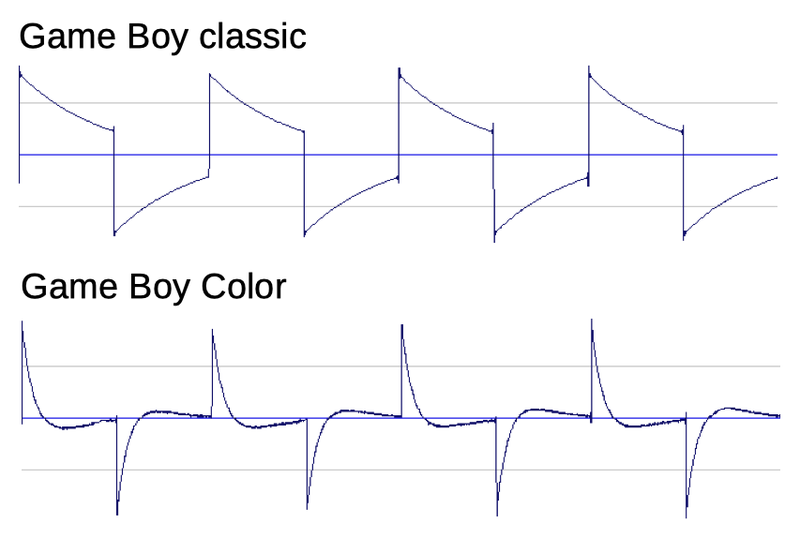

You might wonder how a charge pump can turn a positive voltage into a negative voltage. The trick is a "flying" capacitor, as shown below. On the left, the capacitor is charged to 5 volts. Now, disconnect the capacitor and connect the positive side to ground. The capacitor still has its 5-volt charge, so now the low side must be at -5 volts. By rapidly switching the capacitor between the two states, the charge pump produces a negative voltage.

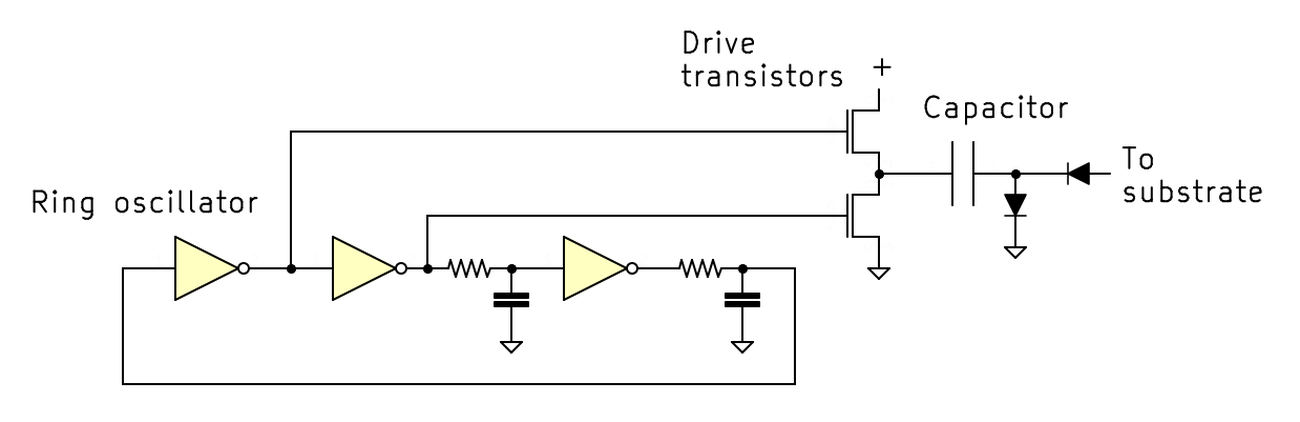

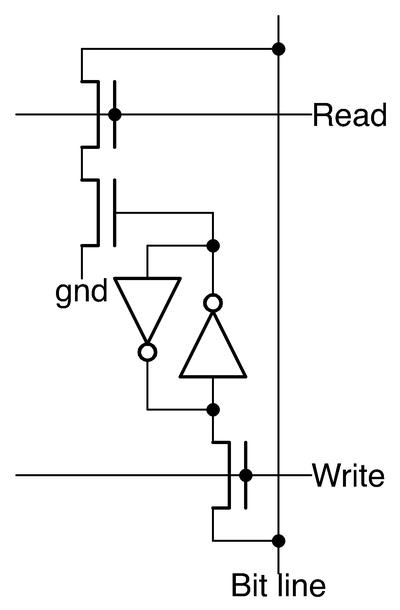

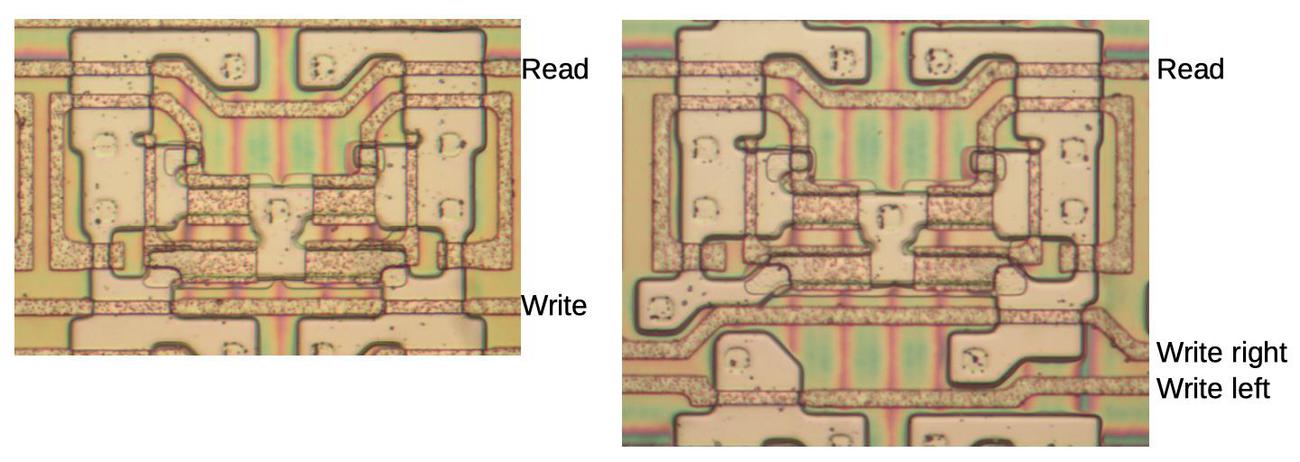

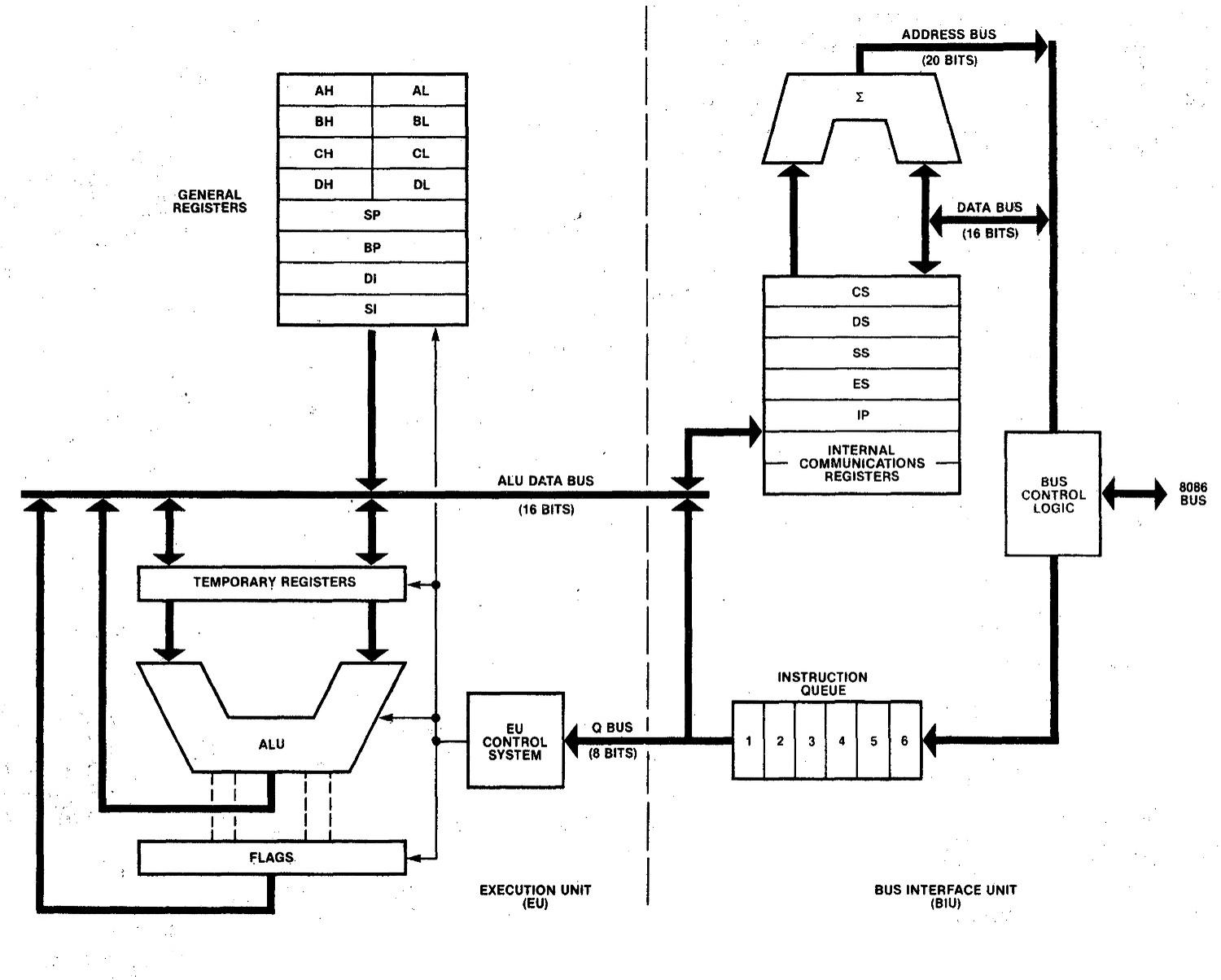

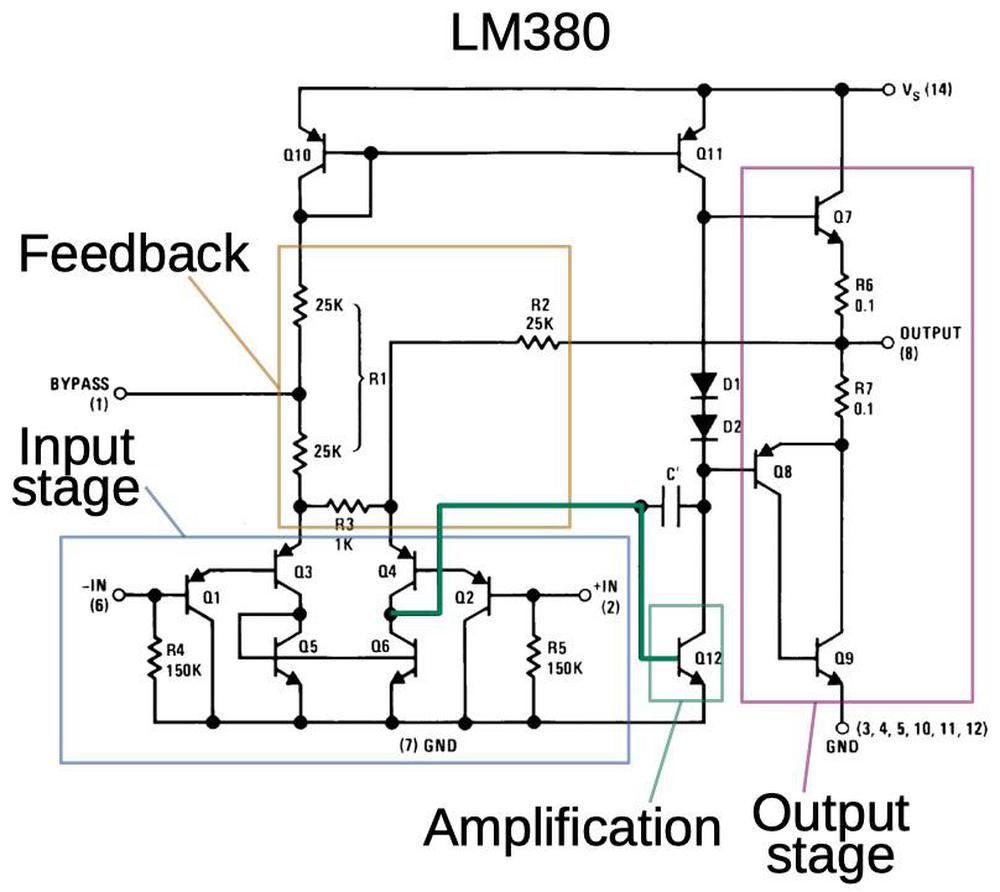

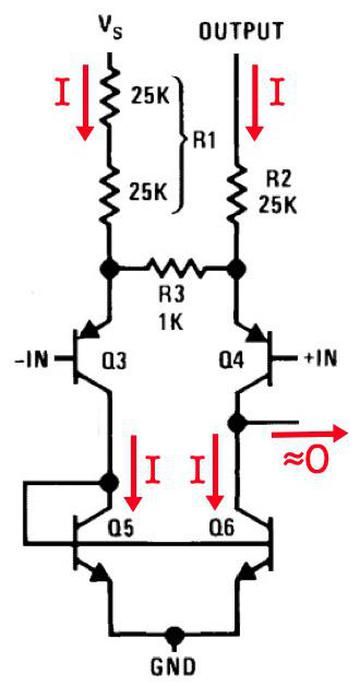

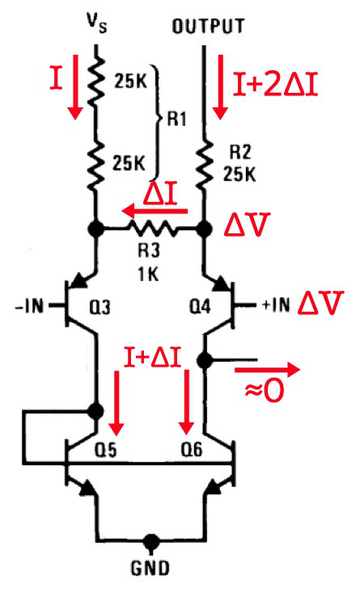

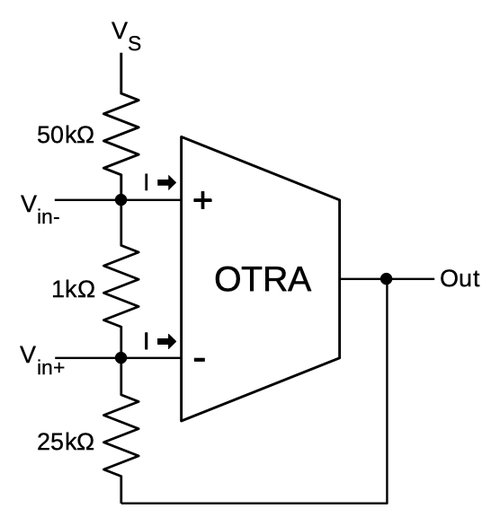

The 8086's charge pump circuit uses MOSFET transistors and diodes to switch the capacitor between the two states, with an oscillator to control the transistors, as shown in the schematic below. The ring oscillator consists of three inverters connected in a loop (or ring). Because the number of inverters is odd, the system is unstable and will oscillate.5 For instance, if the input to the first inverter is 0, its output will be 1, the second output will be 0, and the third output will be 1. This will flip the first inverter, and the "flip" will travel through the loop causing oscillation. To slow down the oscillation rate, two resistor-capacitor networks are inserted into the ring. Since the capacitors will take some time to charge and discharge, the oscillations will be slowed, giving the charge pump time to operate.4

The outputs from the ring oscillator are fed to the transistors that drive the capacitor. In the first step, the upper transistor is switched on, causing the capacitor to charge through the first diode to 5 volts with respect to ground. The second step is where the magic happens. The lower transistor turns on, connecting the high side of the capacitor to ground. Since the capacitor is still charged to 5 volts, the low side of the capacitor must now be at -5 volts, producing the desired negative voltage. This goes through the second diode and the bond wire to the substrate. When the oscillator flips again, the upper transistor turns on and the cycle repeats. The charge pump gets its name because it pumps charge from the output to ground.6 The diodes are similar to check valves in a water pump, making sure charge moves in the right direction.

The implementation in silicon

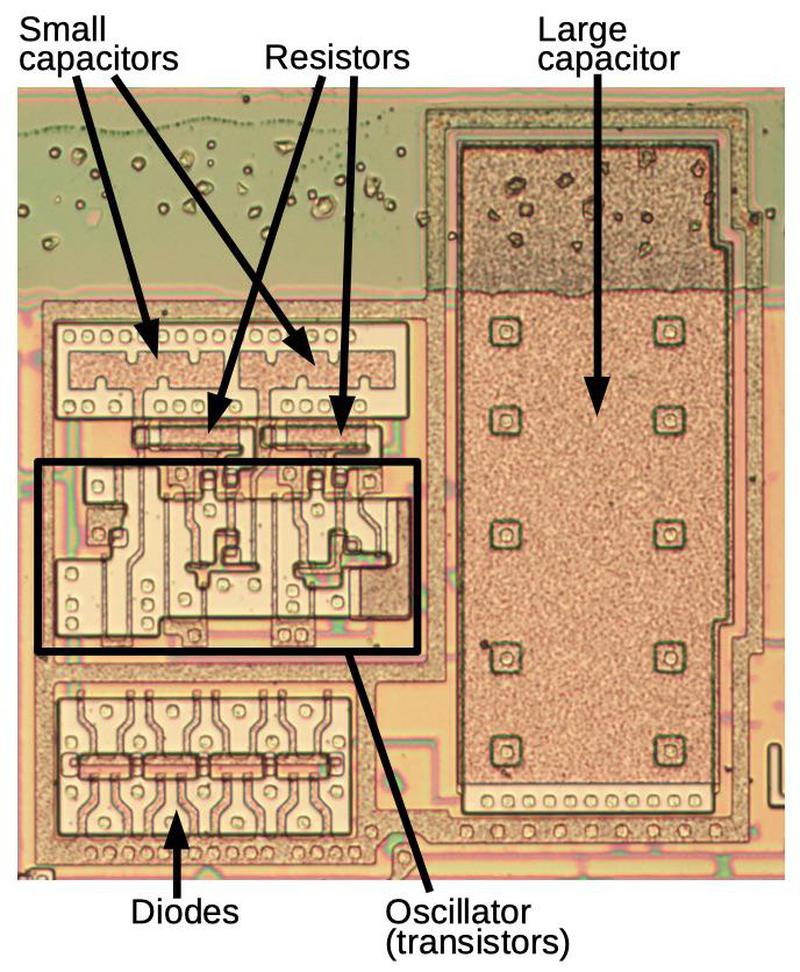

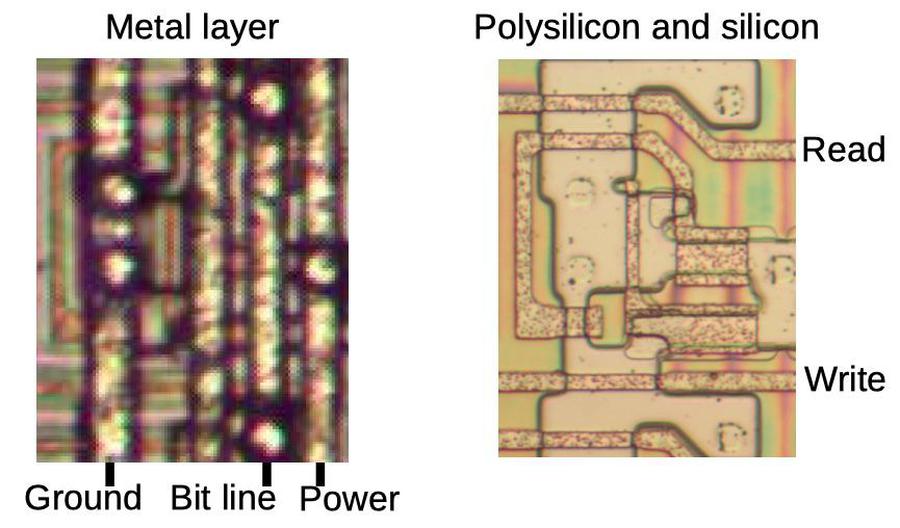

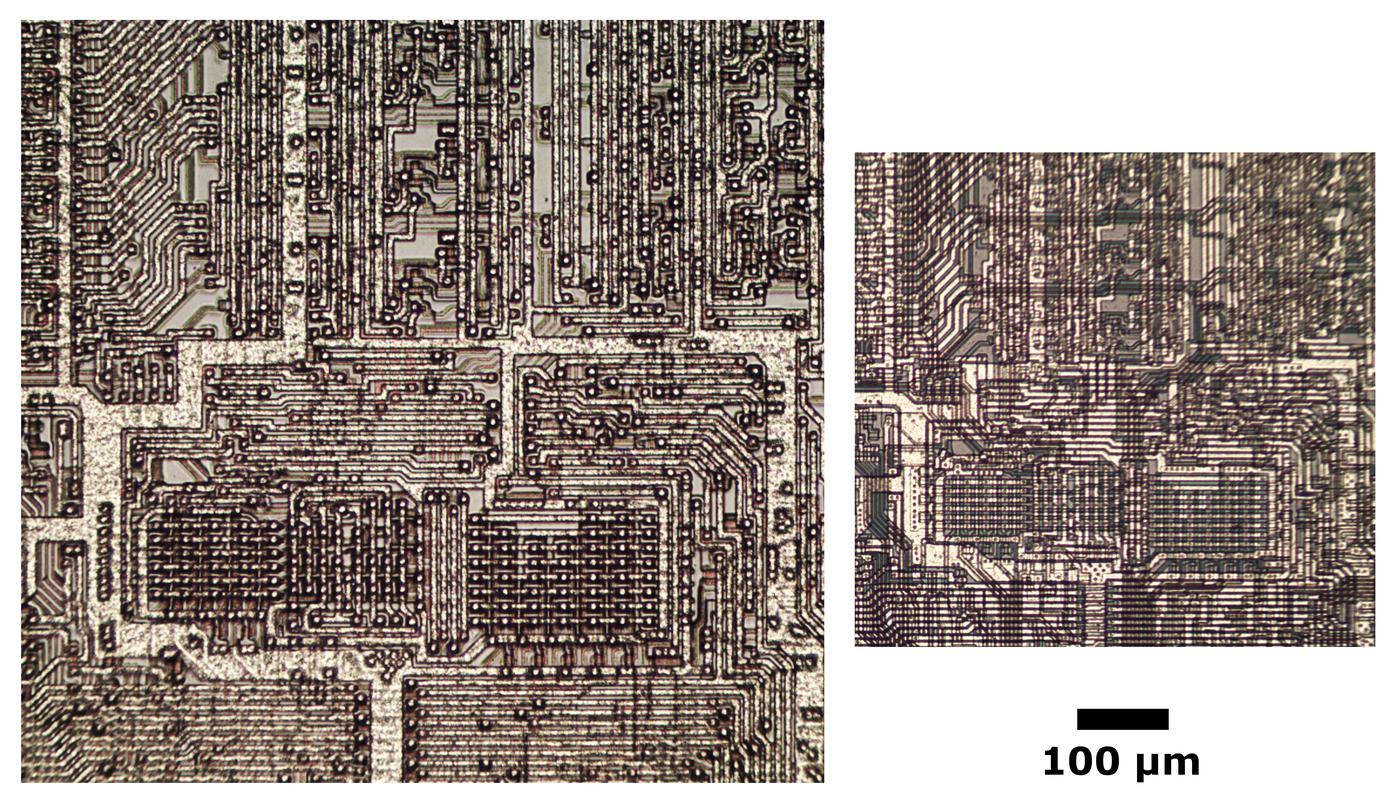

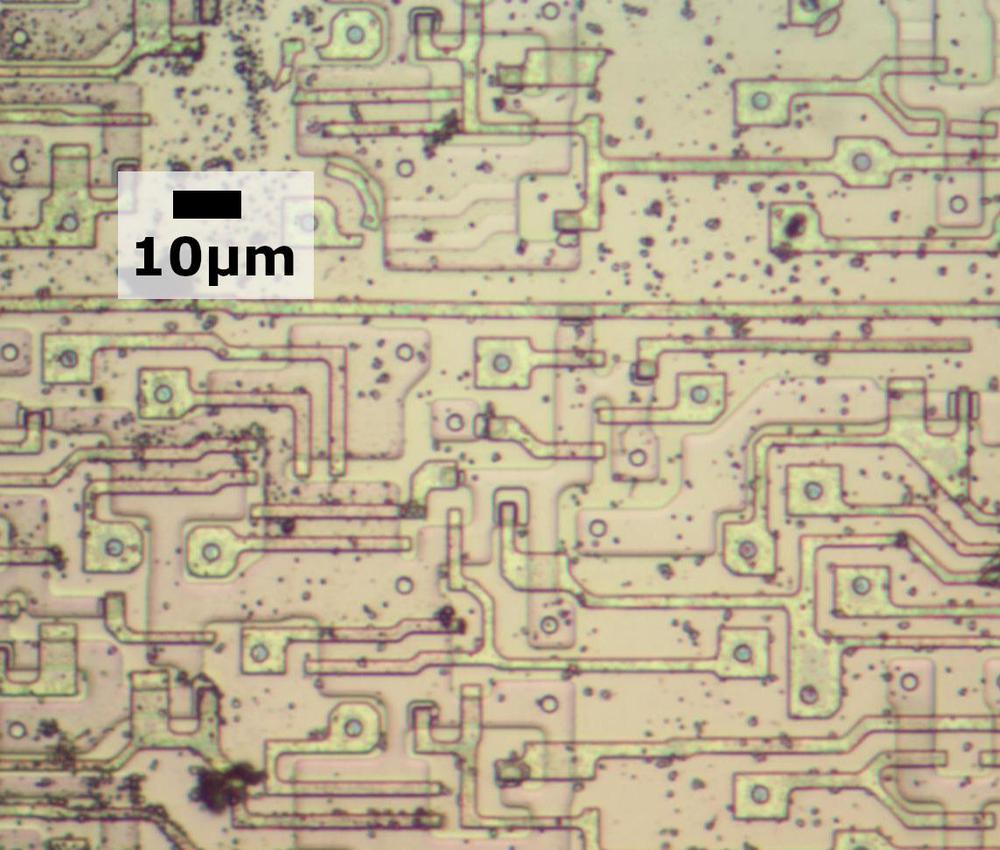

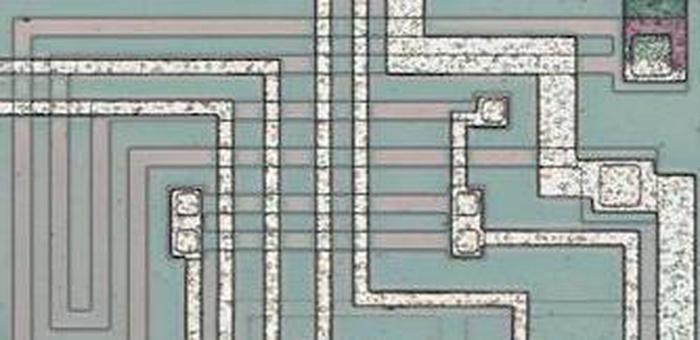

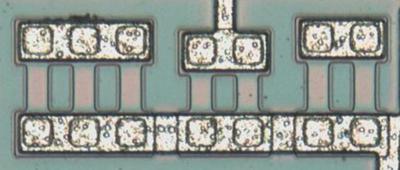

The photo below shows the charge pump as it is implemented on the chip. In this photo, the metal wiring is visible on top, with reddish polysilicon underneath and beige silicon at the bottom. The main capacitor is visible in the center, with H-shaped wiring connecting it to the circuitry on the left. (Part of the capacitor is hidden under the wide metal power trace at the top.) On the right, the substrate bond wire is attached to the pad. A test pattern is below the pad; it has a square for each mask used to produce a layer of the chip.

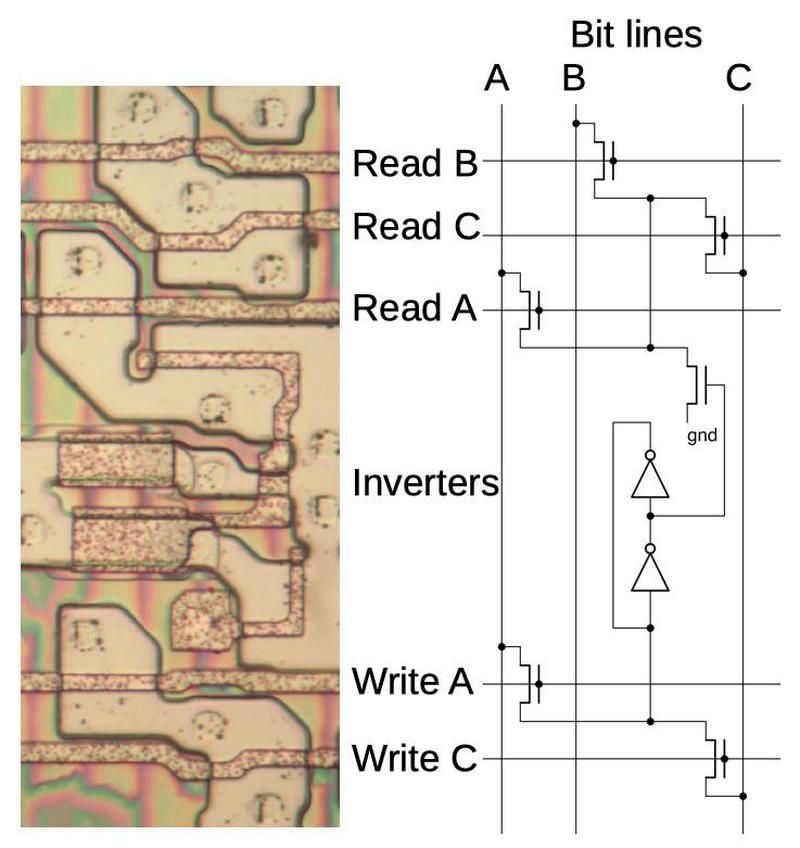

Removing the metal layer shows the circuitry more clearly, below. The large charge pump capacitor takes up the right half of the photo. Although microscopic, this capacitor is huge by chip standards, about the size of a 16-bit register. The capacitor consists of polysilicon over a silicon region, separated by insulating oxide; the polysilicon and silicon form the plates of the capacitor. On the left side are the smaller capacitors and the resistors that provide the R-C delay for the oscillator. Below them is the oscillator circuitry and the drive transistors.7

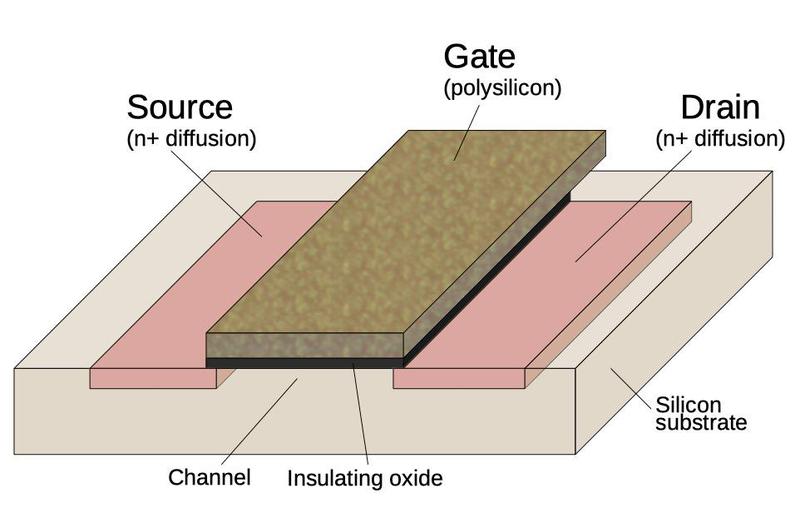

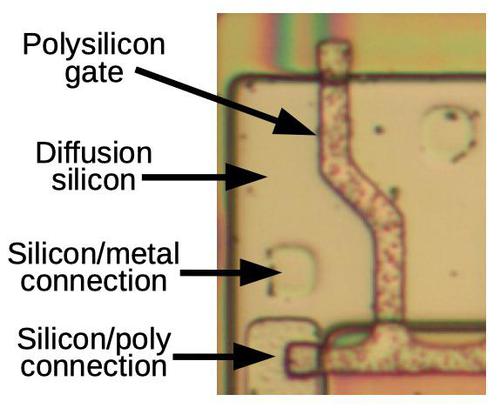

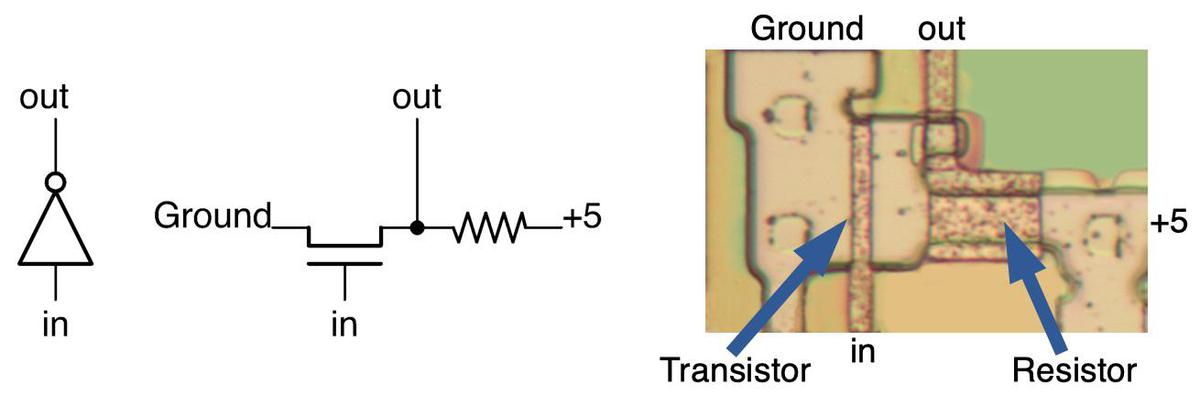

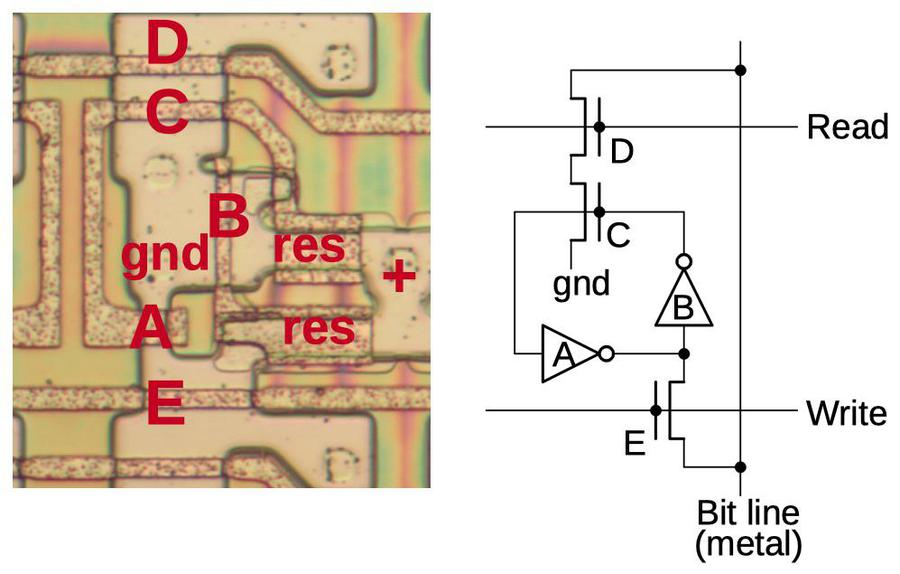

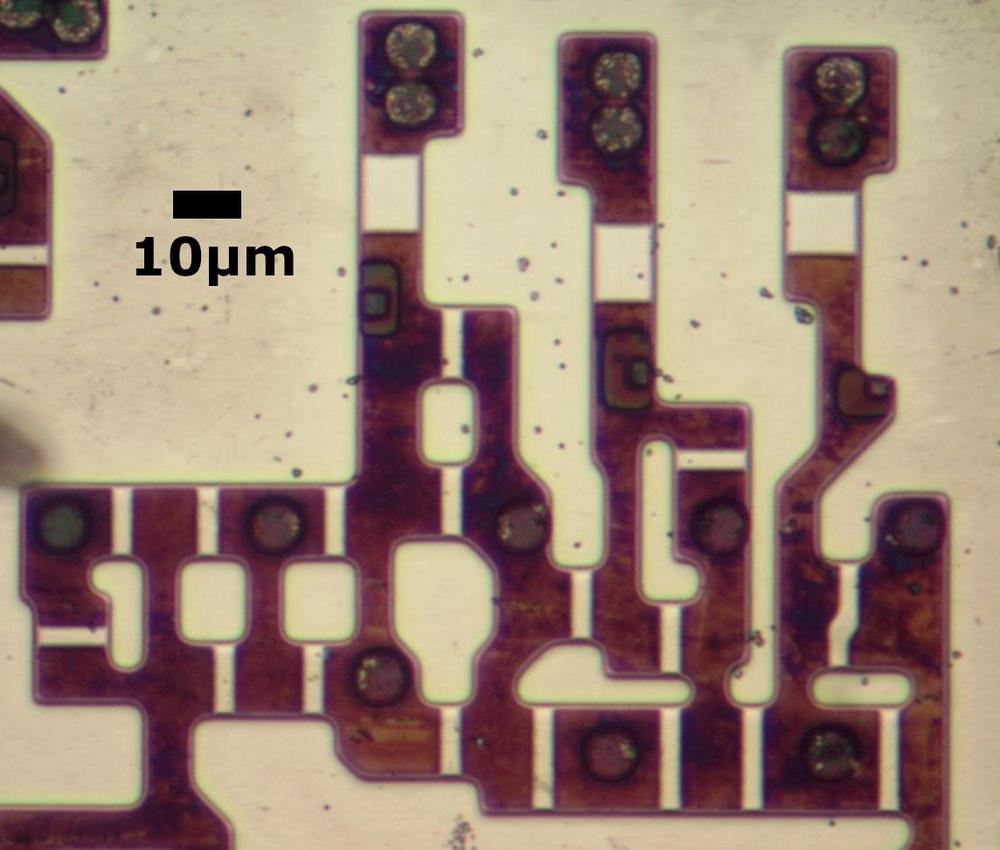

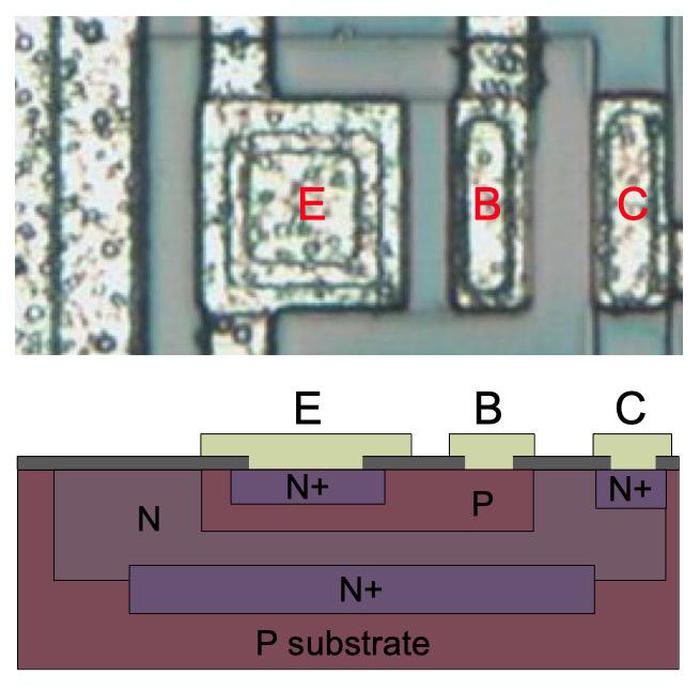

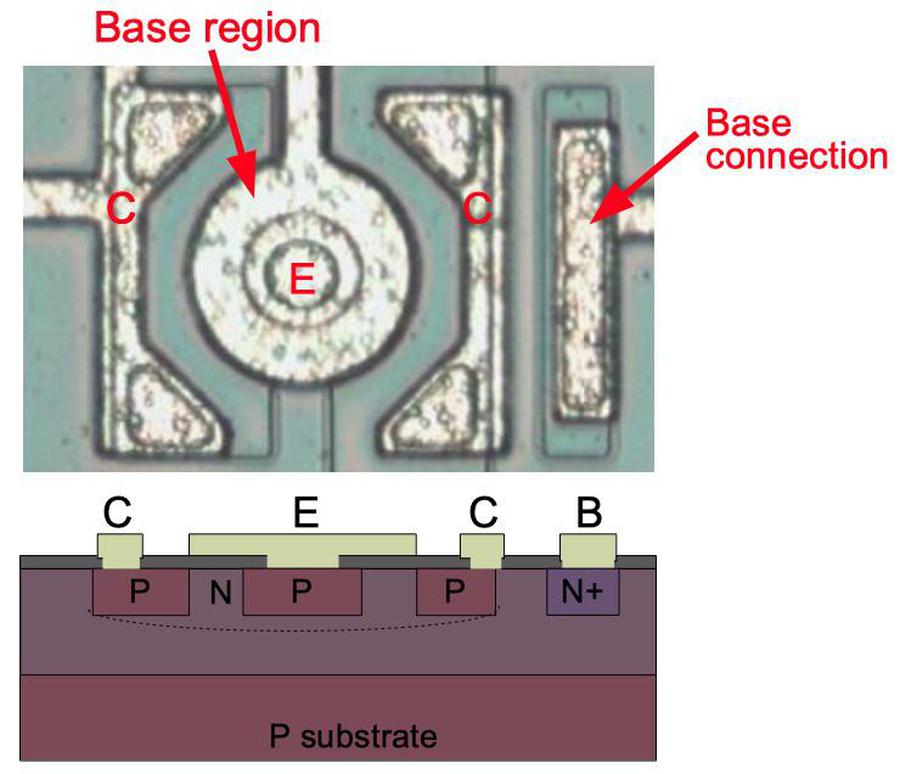

One interesting feature of the charge pump is the two diodes, each built from eight transistors in a regular pattern. The diagram below shows the structure of a transistor. Regions of the silicon are doped with impurities to create diffusion regions with desired properties. The transistor can be viewed as a switch, allowing current to flow between two diffusion regions called the source and drain. The transistor is controlled by the gate, made of a special type of silicon called polysilicon. A high voltage on the gate lets current flow between the source and drain, while a low voltage blocks current flow. These tiny transistors can be combined to form logic gates, the components of microprocessors and other digital chips. But in this case, the transistors are used as diodes.

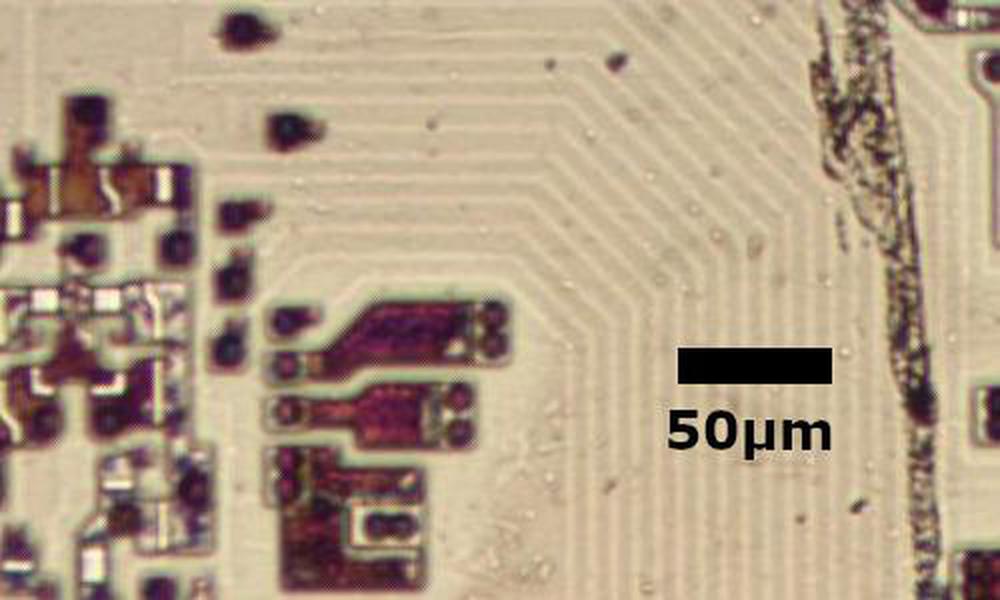

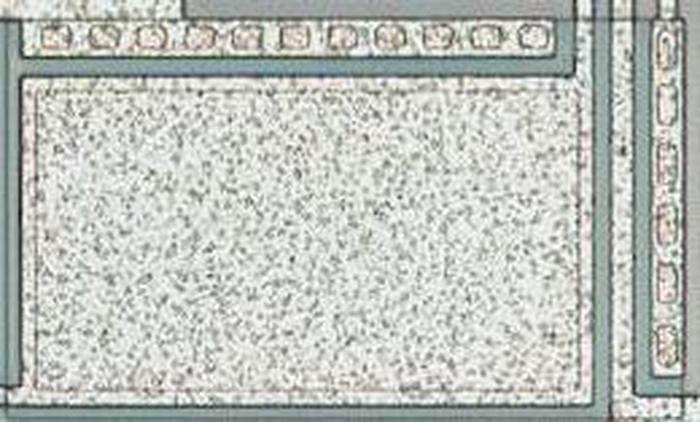

The photo below shows a transistor in the charge pump, viewed from above. As in the diagram, polysilicon forms the gate between the silicon diffusion regions on either side. A diode can be formed from a MOSFET by connecting the gate and drain together (details) through the silicon/polysilicon connection at the bottom of the photo. The silicon can also be connected to the metal layer through a "via". The metal layer was removed for this photo, but faint circles indicate the position of silicon/metal vias.

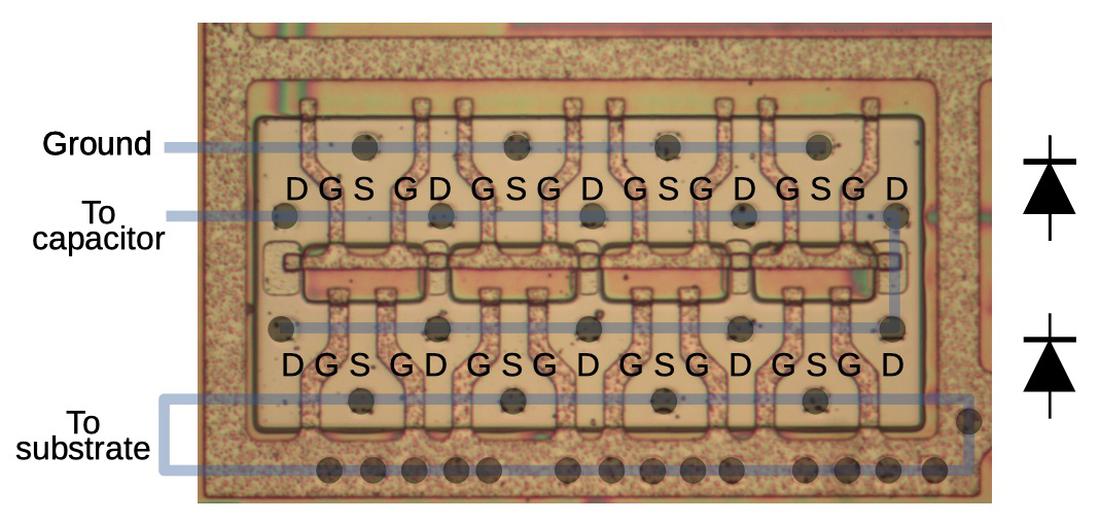

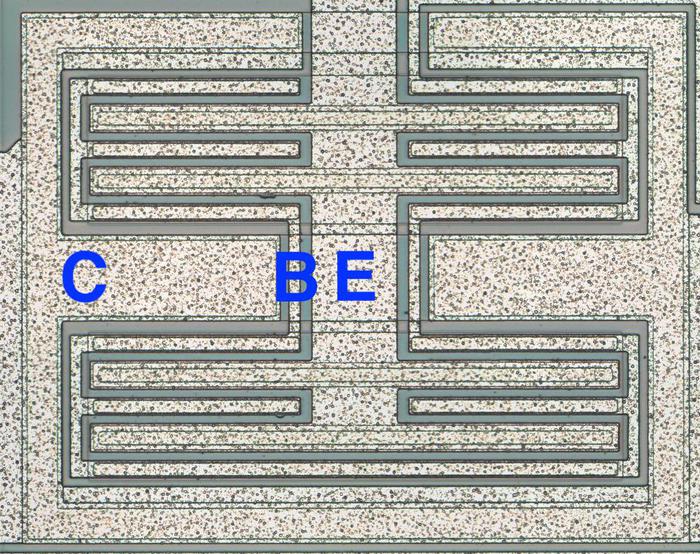

The diagram below shows how the two diodes are implemented from 16 transistors. To support the relatively high current of the charge pump, eight transistors are used in parallel for each diode. Note that neighboring transistors share source or drain regions, allowing transistors to be packed densely. The blue lines indicate the metal wires; the metal was removed for this photo. The dark circles indicate connections (vias) between the metal and silicon.

Putting this all together, the upper eight transistors have their sources connected to ground by a metal wire. Their gates and drains connected together by the polysilicon below the transistors, making them into diodes, and they are connected to the capacitor by a metal wire. The lower eight transistors form a second diode; their gates and drains are wired together by the lower metal wire loop. Note how the layout has been optimized; for example, the gates have bent shapes to avoid the vias (black dots).

Conclusions

The substrate bias generator on the 8086 chip9 is an interesting combination of digital circuitry (a ring oscillator formed from inverters) and an analog charge pump. While the bias generator may seem like an obscure part of 1970s computer history, bias generation is still part of modern integrated circuits. It is much more complex in modern chips which have multiple carefully regulated biases in multiple power domains. 8 In a sense it is analogous to the x86 architecture, something that started in the 1970s and is even more popular today, but has become unimaginably more complex in the quest for higher performance.

If you're interested in the 8086, I wrote about the 8086 die, its die shrink process and the 8086 registers earlier. I plan to analyze the 8086 in more detail in future blog posts so follow me on Twitter @kenshirriff or RSS for updates.

Notes and references

-

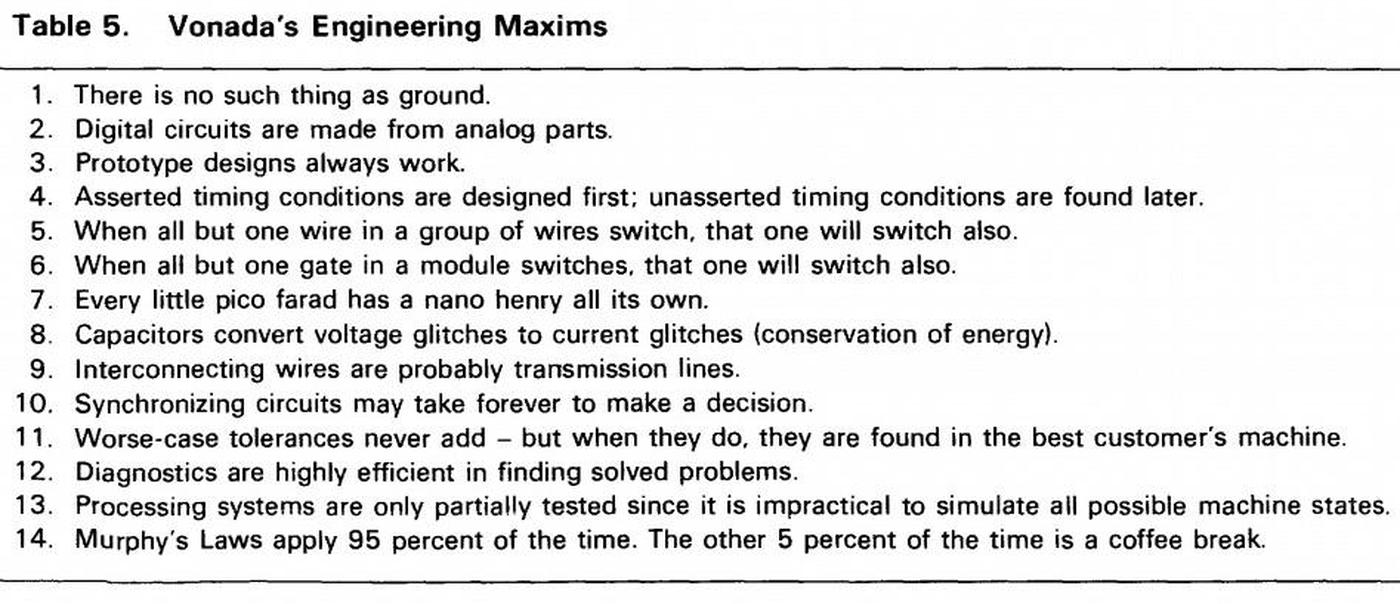

Strictly speaking, the entire chip is analog: there's an old saying that "Digital computers are made from analog parts". This saying came from DEC engineer Don Vonada and was published in DEC's Computer Engineering in 1978.

Vonada's Engineering Maxims (text). -

Putting a negative bias voltage on the substrate had several benefits. It decreased parasitic capacitance making the chip faster, made the transistor threshold voltage more predictable, and reduced leakage current. ↩

-

Early DRAM memory chips and microprocessor chips often required three supplies: +5V (Vcc), +12V (Vdd) and -5V (Vbb) bias voltage. In the late 1970s, improvements in chip technology allowed a single supply to be used instead. For example, Mostek's MK4116 (a 16 kilobit DRAM from 1977) required three voltages while the improved MK4516 (1981) operated on a single +5V supply, simplifying hardware designs. (Amusingly, some of these chips still kept the Vbb and Vcc pins for backward compatibility but left them unconnected.) Intel's memory chips followed a similar path, with the 2116 DRAM (16K, 1977) using three voltages and the improved 2118 (1979) using a single voltage. Similarly, the famous Intel 8080 microprocessor (1974) used enhancement-mode transistors and required three voltages. An improved version, the 8085 (1976), used depletion-mode transistors and was powered by a single +5V supply. The Motorola 6800 microprocessor (1974) used a different approach for a single supply; although the 6800 was built from the older enhancement-load transistors it avoided the +12 supply by implementing an on-chip voltage doubler, a charge pump that increased the voltage. ↩

-

I tried to measure the frequency of the charge pump by looking at the chip's current to see fluctuations due to the charge pump. I measured 90 MHz fluctuations, but I suspect I was measuring noise and not the charge pump's oscillations. ↩

-

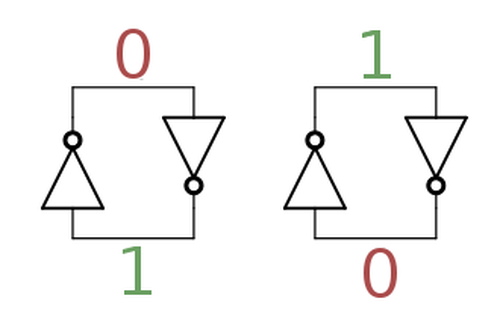

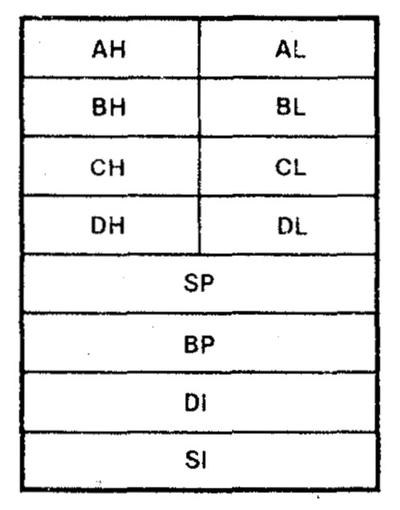

Because the circuit has an odd number of inverters, it oscillates. If, on the other hand, it had an even number of inverters, it would be stable in two different states. This technique is used in the 8086's registers: a pair of inverters stores each bit (details). ↩

-

I've simplified the charge pump discussion slightly. Due to voltage drops in the transistors, the substrate voltage will probably be around -3V, not -5V. (If a chip requires a larger voltage drop, charge pump stages can be cascaded.) For the pump direction, I'm referring to current flow. If you think of it as pumping electrons, the negative electrons are being pumped the opposite direction, into the substrate. ↩

-

The oscillator is built from 13 transistors. Seven transistors form the 3 inverters (one inverter has an extra transistor to provide extra output current. The six drive transistors consist of two transistors pulling the output high and four transistors pulling the output low. The layout is strangely different from normal inverter circuitry, probably because the current requirements are different from normal digital logic. ↩

-

Bias generators are now available as IP blocks that can be licensed and be plugged into a chip design. For more information on bias in modern chips, see Body bias, Multi bias domain implementation, or this presentation. There is even a standard IEEE 1801 power format that allows IC design tools to generate the necessary circuitry. ↩

-

The Intel 8087, the math coprocessor chip that goes along with the 8086, also has a substrate bias generator. It uses the same principles, but unexpectedly has a different circuit, using 5 inverters. I wrote about it in detail here. ↩