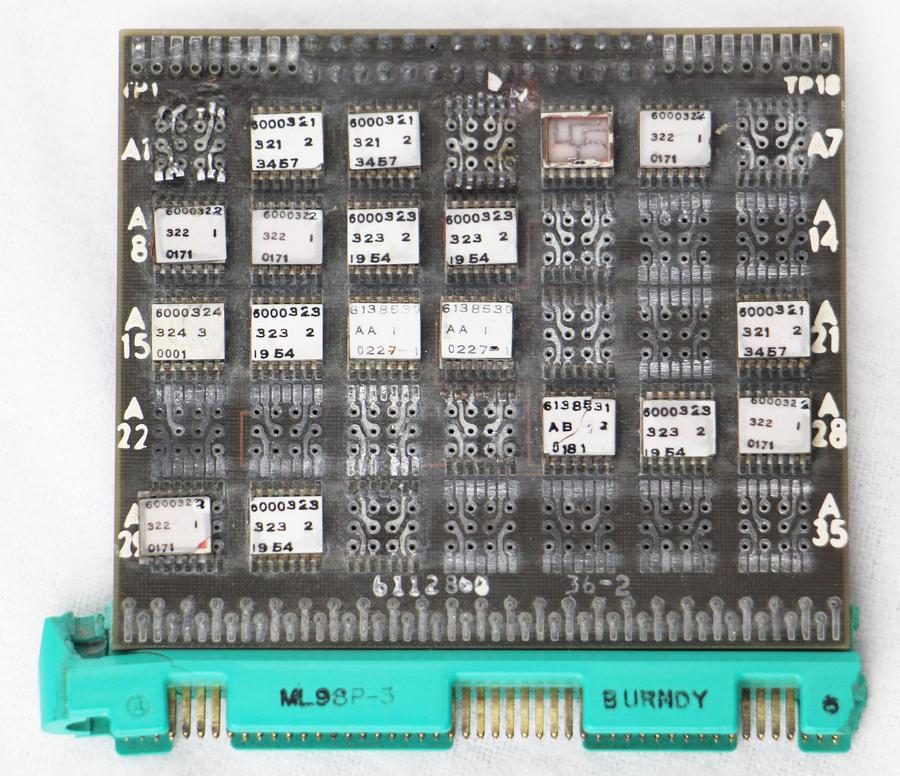

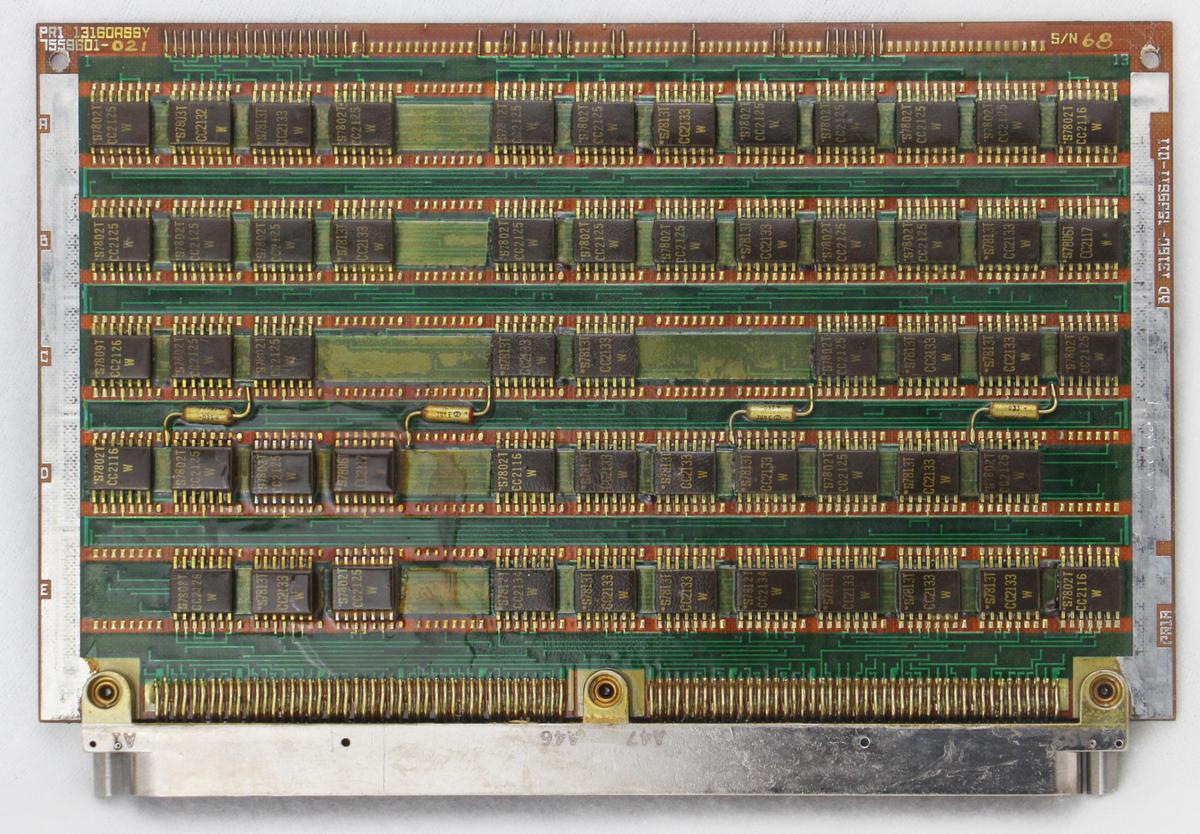

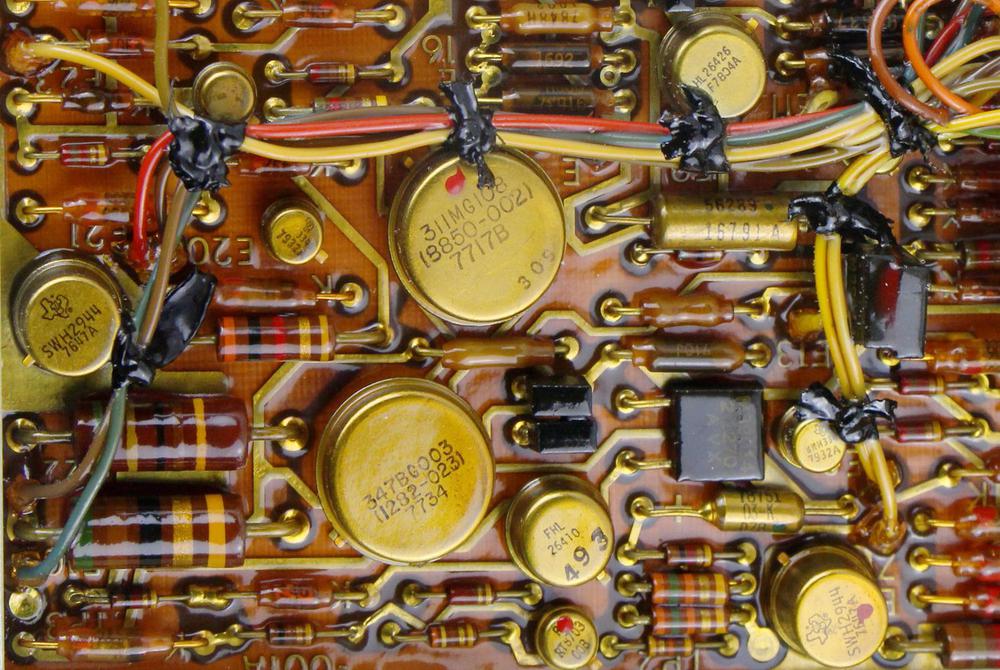

In the Apollo Moon missions, the Saturn V rocket was guided by an advanced onboard computer system built by IBM. This system was built from hybrid modules, similar to integrated circuits but containing individual components. I reverse-engineered a circuit board from this system and determined its function: Inside the computer's I/O unit, the board selected different data sources for the computer.

This post explains how the board worked, from the tiny silicon dies inside its hybrid modules to the board's circuitry and its wiring in the rocket. This board was first studied by Fran Blanch in The Apollo Saturn V LVDC Project. Then EEVblog made a video about it. Now it's my turn to analyze the board.

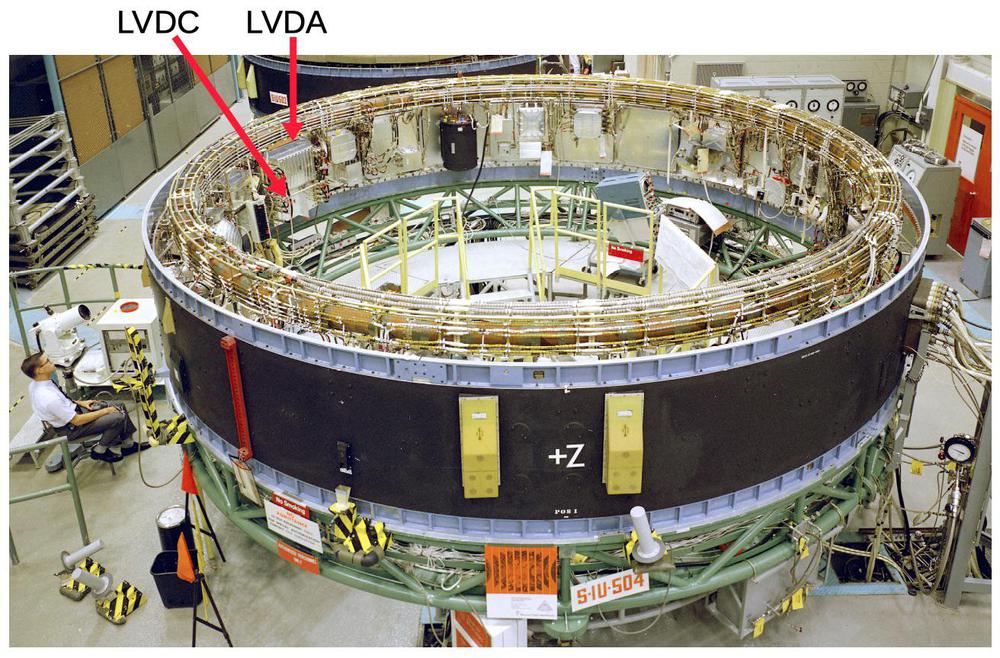

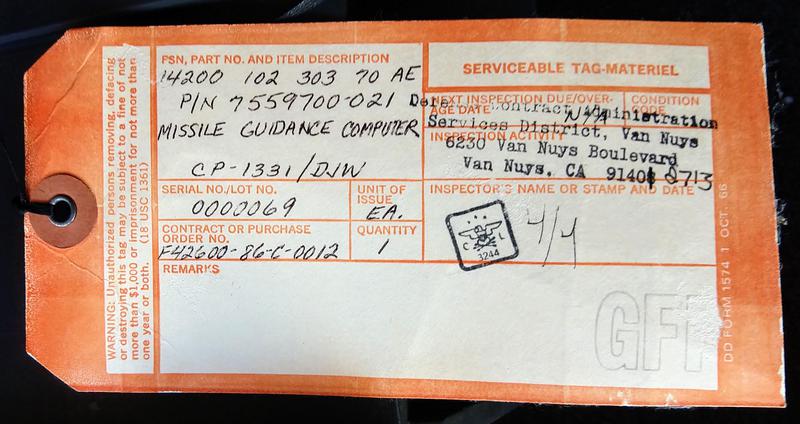

The Launch Vehicle Digital Computer (LVDC) and Launch Vehicle Data Adapter (LVDA)

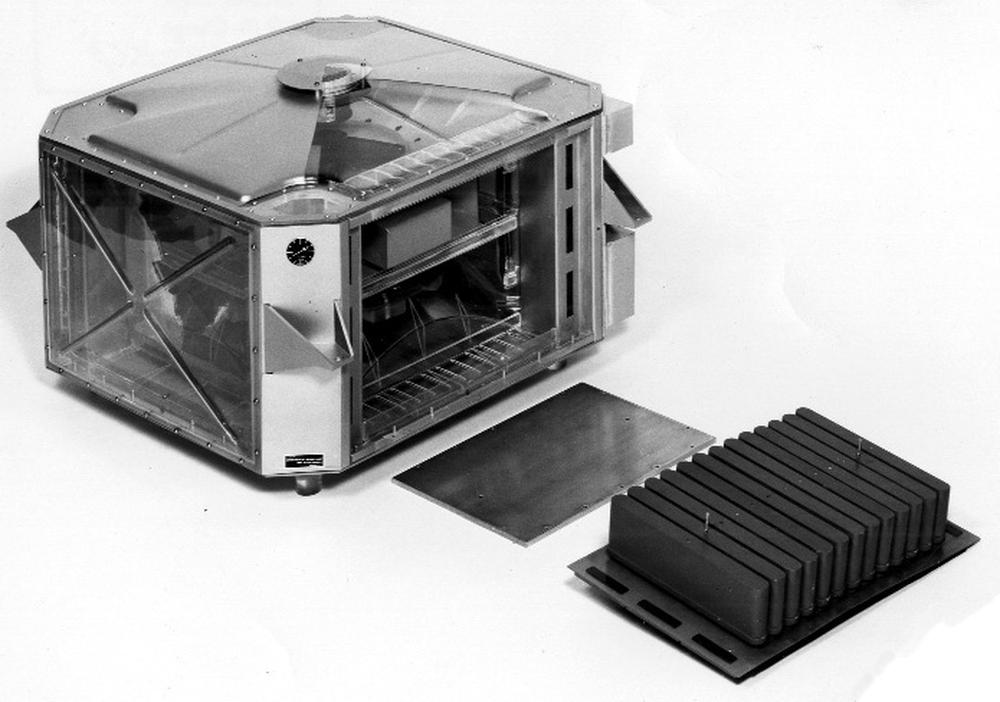

The race to the Moon started on May 25, 1961, when President Kennedy stated that America would land a man on the Moon before the end of the decade. This mission required the three-stage Saturn V rocket, the most powerful rocket ever built. The Saturn V was guided and controlled by the Launch Vehicle Digital Computer (below), from liftoff into Earth orbit, and then on a trajectory towards the Moon.1 In an era when most computers ranged from refrigerator-sized to room-filling, the LVDC was very compact and weighed just 80 pounds since it was mounted inside the rocket. The downside was that it was very slow, performing 12,000 instructions a second.

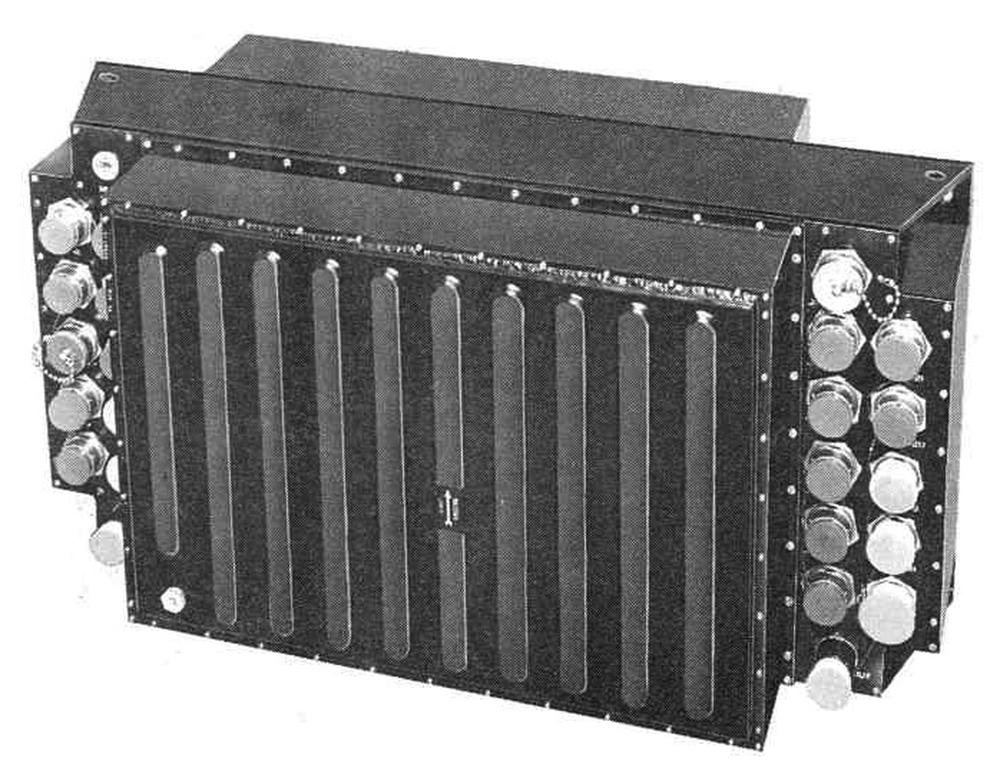

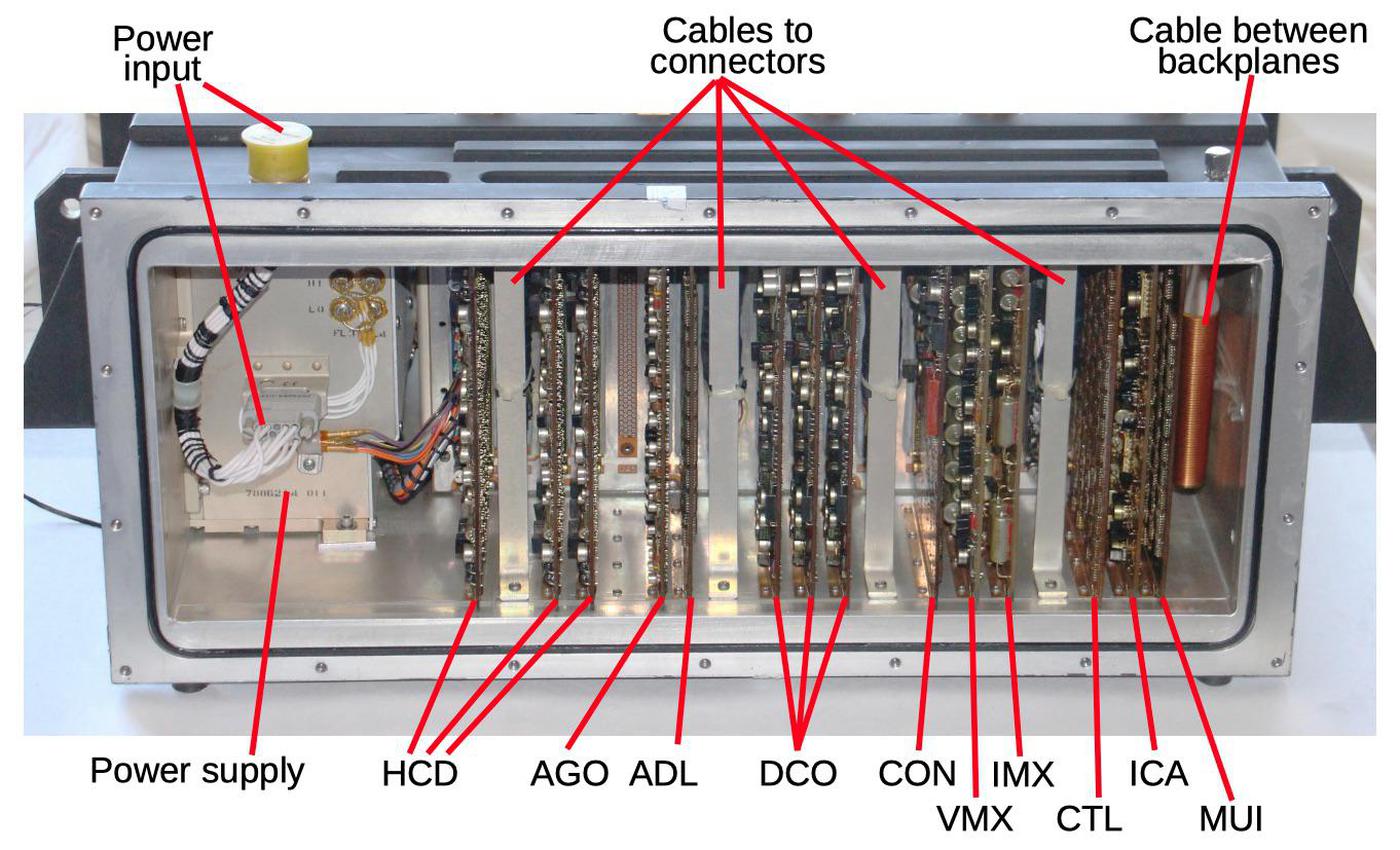

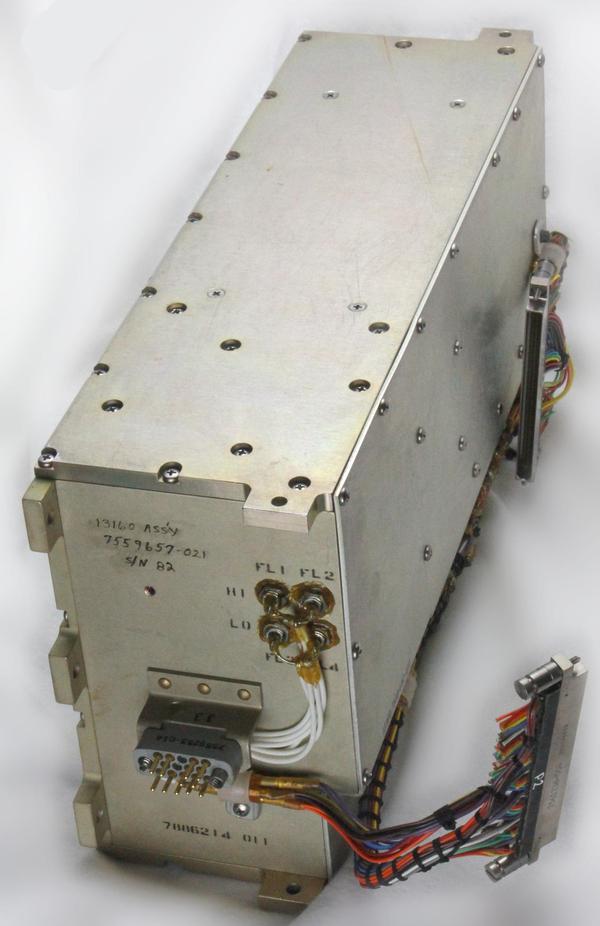

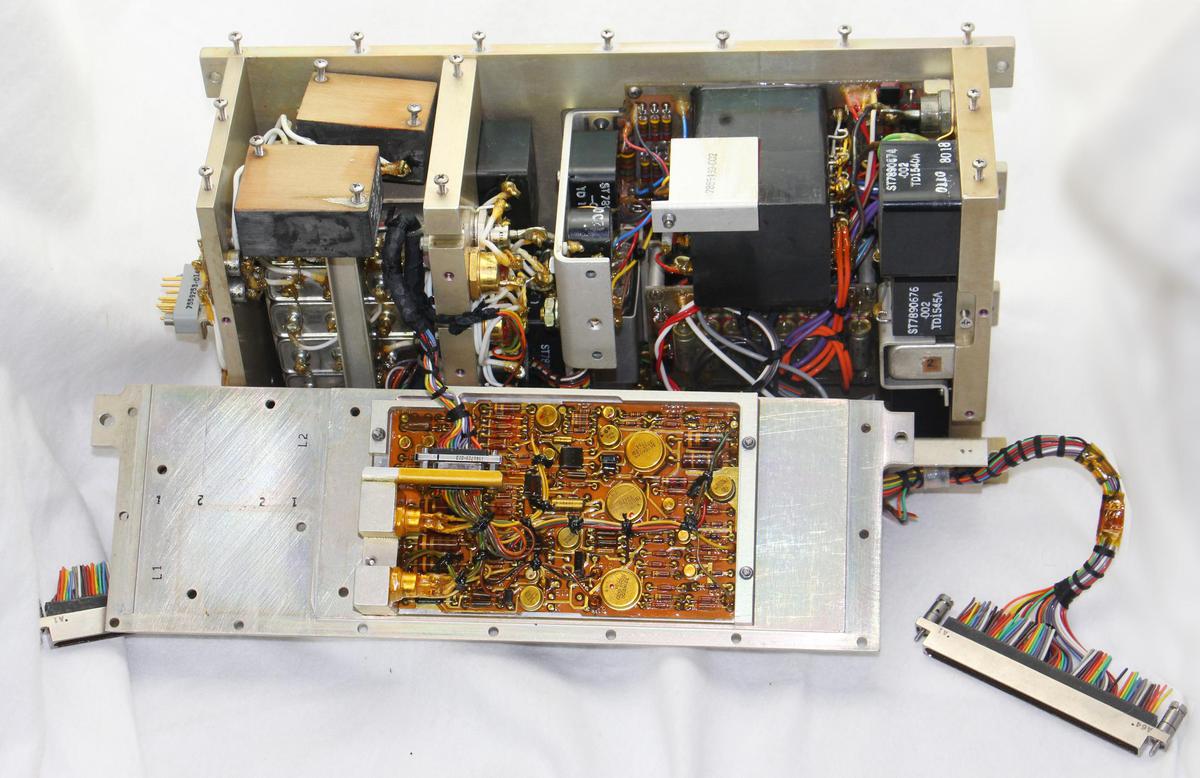

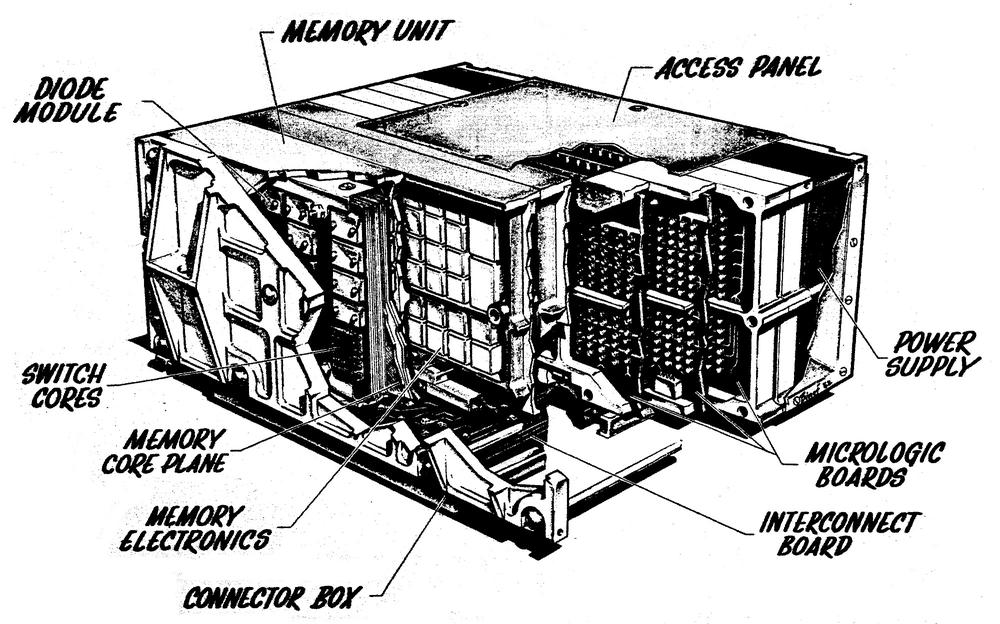

The LVDC worked in conjunction with the Launch Vehicle Data Adapter (LVDA, below), which provided the input/output functions for the computer. All communication between the computer and the rocket went through the LVDA, which converted the rocket's analog signals and 28-volt control signals to the serial binary data the computer required. The LVDA contained buffers (implemented with glass delay lines) and control registers for its various functions. The LVDA had analog-to-digital converters to read data from the inertial measurement unit's gyroscopes and digital-to-analog converters to provide control signals to the rockets. It also processed telemetry signals that were sent to the ground and received ground-based commands for the computer. Finally, power to the LVDC was provided by redundant switching power supplies in the LVDA.

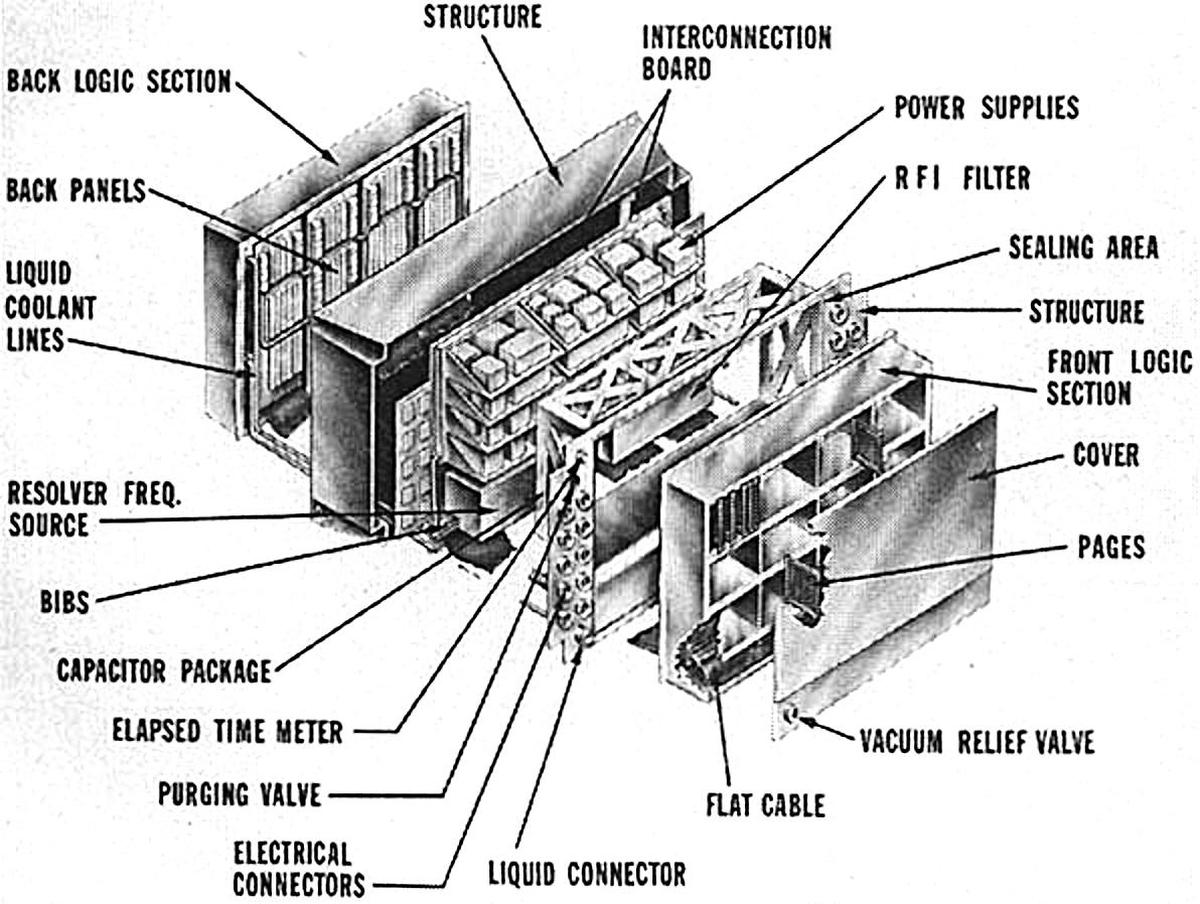

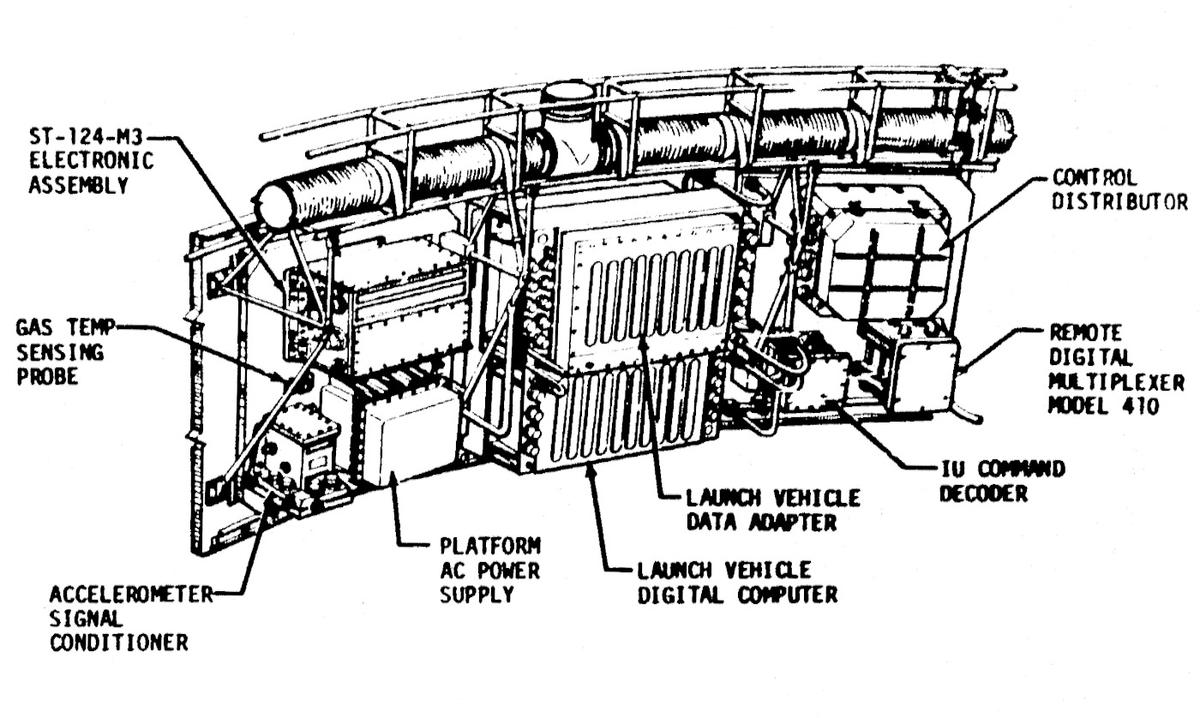

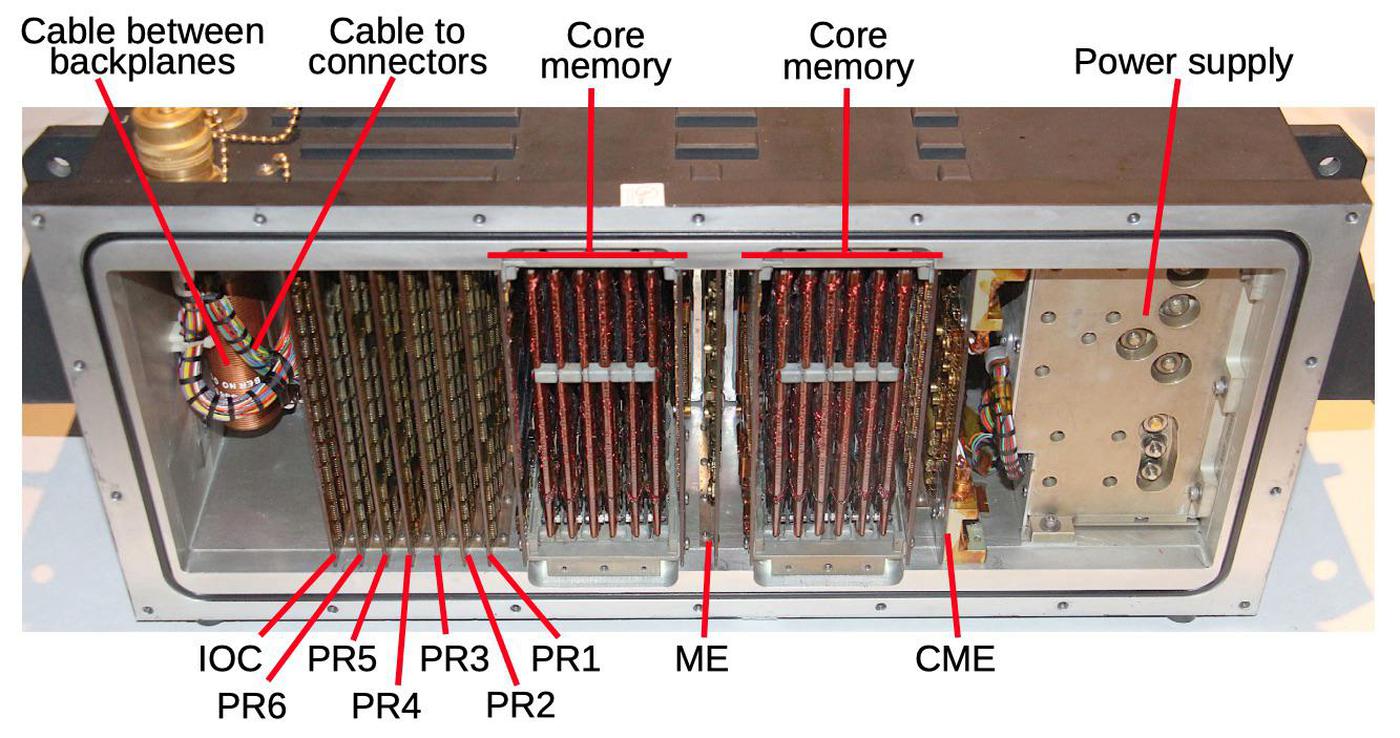

Because the LVDA had so many different functions, it was almost twice the size of the LVDC computer. The diagram below shows the circuitry crammed into the 176-pound LVDA.2 It had two sections filled with circuit boards called "pages": the front logic section and the back logic section. (The board I examined was from the front logic section.) The power supplies and filters were in the central section. A methanol coolant solution flowed through channels in the LVDA to keep it cool. The LVDA was wired to the LVDC and other parts of the rocket through the 21 round connectors on the ends.

Diode-Transistor Logic

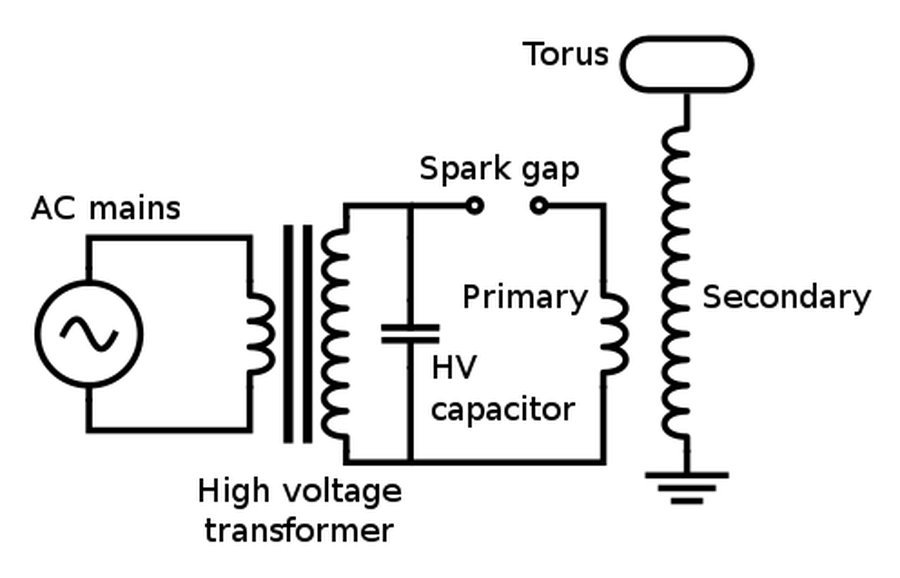

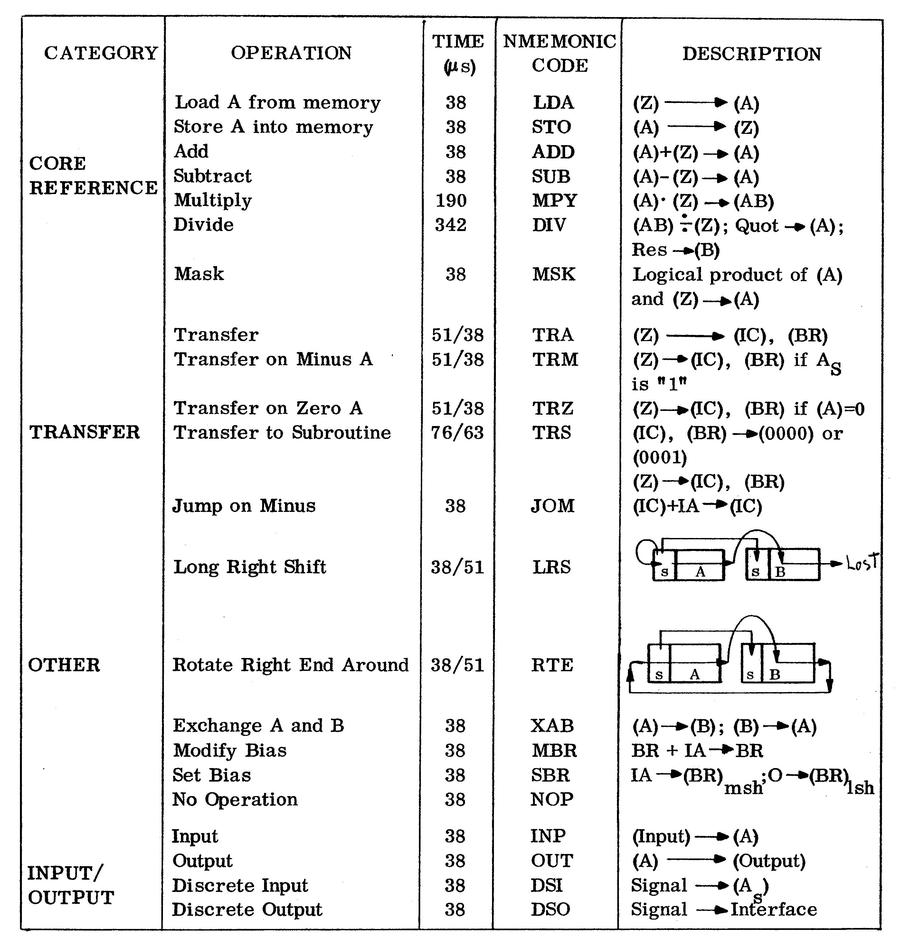

There are many different ways to build logic gates. The LVDC and LVDA used a technique called Diode-Transistor Logic (DTL) that builds a gate from diodes and a transistor. This was more advanced than the Resistor-Transistor Logic (RTL) used by the Apollo Guidance Computer, but inferior to Transistor-Transistor Logic (TTL), which became very popular in the 1970s.

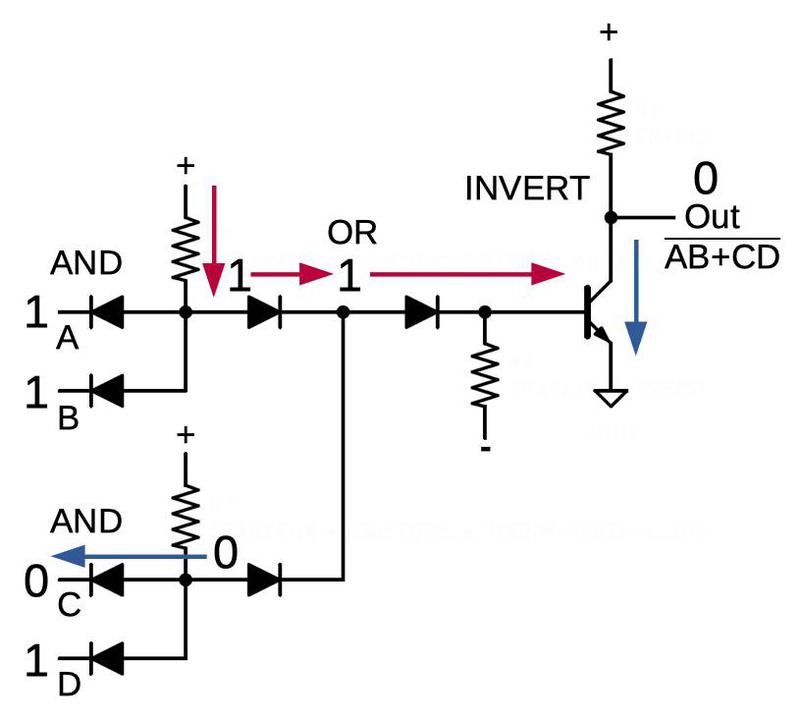

The standard logic gate in the LVDC was an AND-OR-INVERT gate3 that implements a logic function such as (A·B + C·D)'. It gets its name because it ANDs together sets of inputs, ORs them, and finally inverts the results. The AND-OR-INVERT gate was powerful because it could be built with many inputs, e.g. (A·B + C·D·E + F·G·H)'. While the AND-OR-INVERT gate may seem complex, it only required one transistor which was important in an era when every transistor counted.

If you want to understand how the gate works internally, look at the diagram below. It shows a four-input AND-OR-INVERT gate with two AND terms. First consider inputs A and B, which are both set to 1 (high). The pull-up resistor4 pulls the AND value high (red, 1). In comparison, in the lower AND gate, input C is 0, so current flows through input C, pulling the AND value low (blue, 0). Thus, the diodes and the pull-up resistor implement an AND gate. Next, look at the OR stage. Current from the top AND (red) pulls the OR stage high (1). Finally, this current turns the transistor on, pulling the output low (blue, 0) and providing the inversion. If both AND stages were 0, the OR stage wouldn't be pulled high. Instead, the pull-down resistor would pull the OR value low (0), turning off the transistor and causing the output to be pulled high (1).

An AND-OR-INVERT gate could be built with more resistors or diodes to provide as many inputs as required, potentially many inputs to each AND, and many blocks ORed together. You might expect that AND-OR-INVERT gate would be implemented on a single chip, but the LVDC used multiple chips for each gate, as will be shown below. Different chips had various combinations of diodes, resistors, and transistors that were wired up in flexible ways to form the desired logic gate.

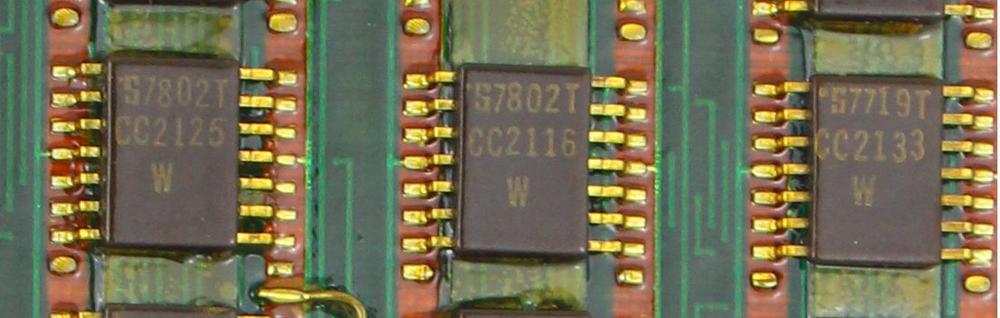

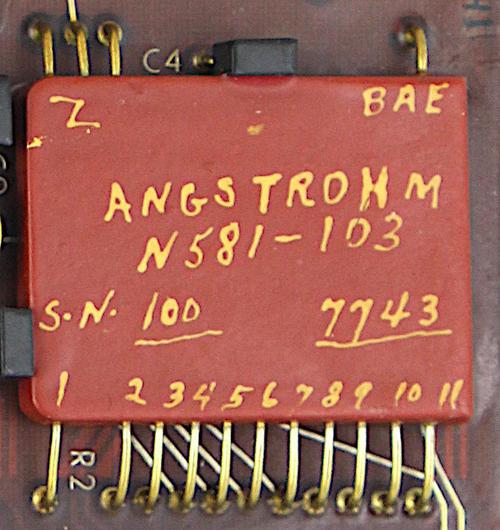

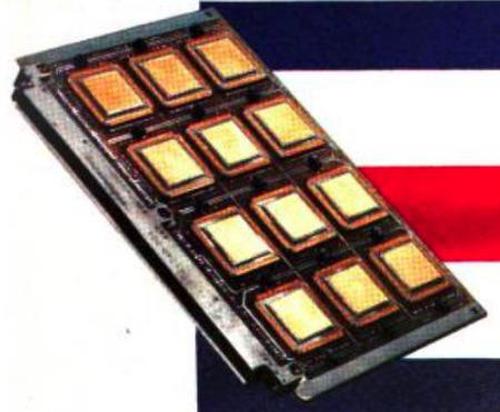

Unit Logic Devices (ULD)

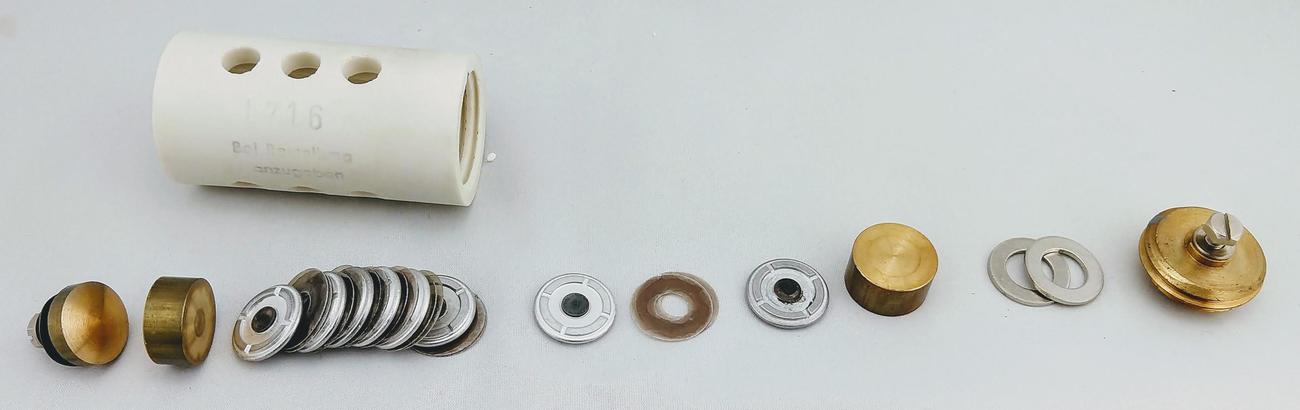

The LVDC and LVDA were built with an interesting hybrid technology called ULD (Unit Logic Devices).5 Although they superficially resembled integrated circuits, ULD modules contained multiple components. They used simple silicon dies, each implementing just one transistor or two diodes. These dies, along with thick-film printed resistors, were mounted on a .3-inch-square ceramic wafer. These modules were a variant of the SLT (Solid Logic Technology) modules used in IBM's popular S/360 series of computers. IBM started developing SLT modules in 1961, before integrated circuits were commercially viable, and by 1966 IBM produced over 100 million SLT modules a year.

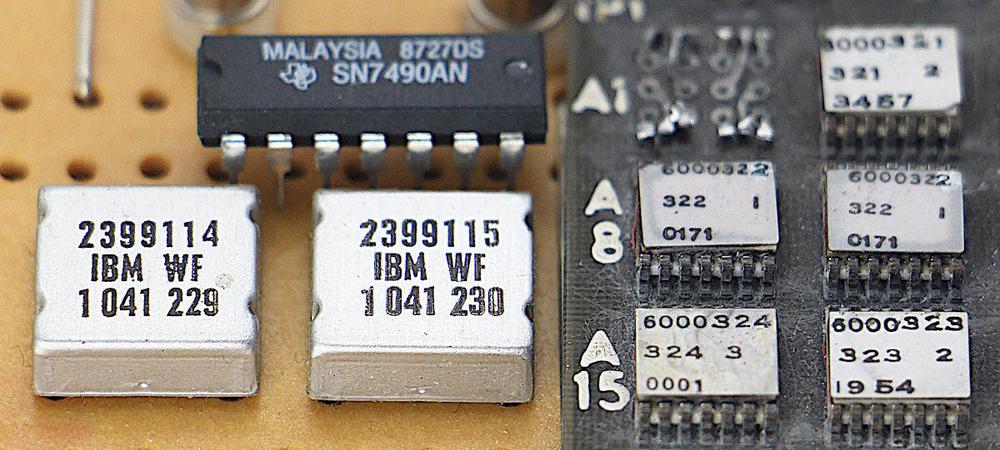

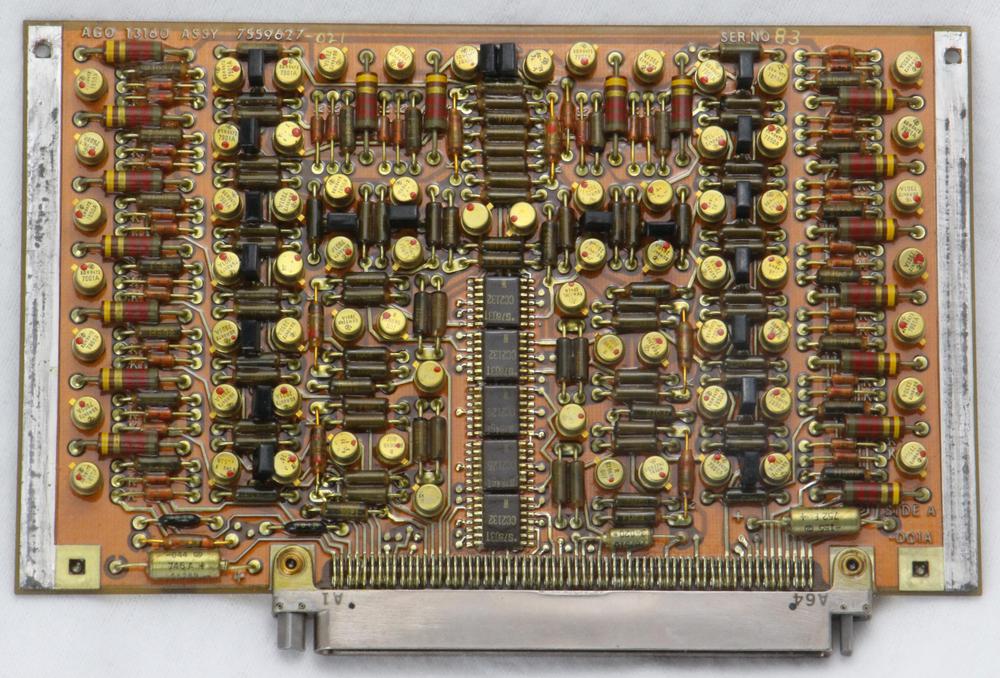

ULD modules were considerably smaller than SLT modules, as shown in the photo below, making them more suitable for a compact space computer. ULD modules used flat-pack ceramic packages instead of SLT's metal cans, and had metal contacts on the upper surface instead of pins. Clips on the circuit board held the ULD module in place and connected with these contacts. The LVDC and LVDA used more than 50 different types of ULDs.

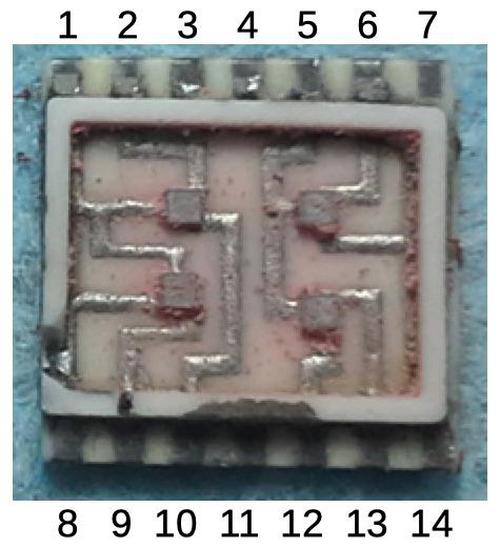

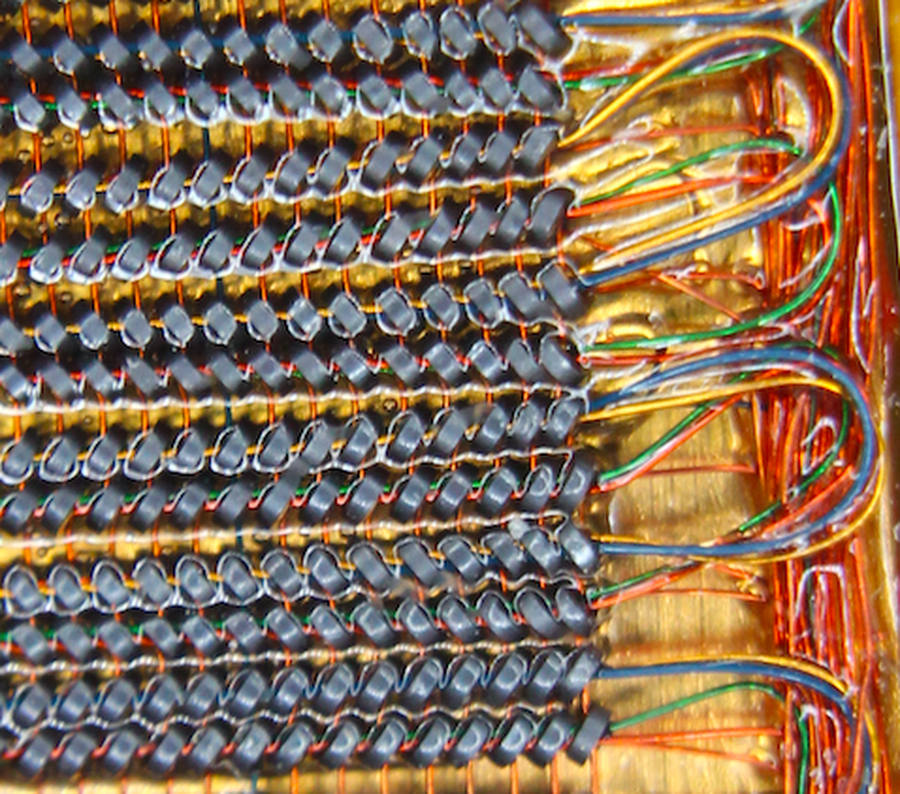

Internally, a ULD module contained up to four tiny square silicon dies. Each die implemented either two diodes or one transistor. The photo below shows the internal components of a ULD module, next to an intact ULD module. On the left, the circuit traces are visible on the ceramic wafer, connected to four tiny square silicon dies. While this looks like a printed circuit board, keep in mind that it is much smaller than a fingernail. Thick-film resistors were printed on the underside of the module, so they are not visible.

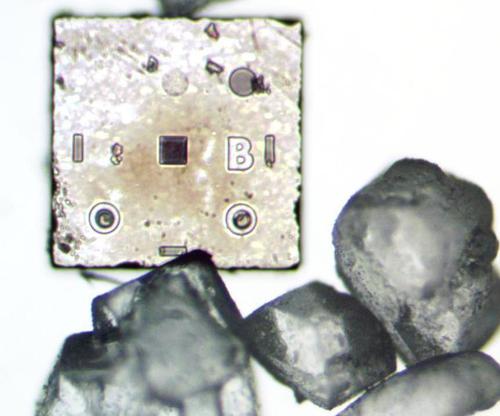

The microscope photo below shows a silicon die from a ULD module that implements two diodes. The die is very small; for comparison, grains of sugar are displayed next to the die. The die had three external connections through copper balls soldered to the three circles. The two lower circles were doped (darker regions) to form the anodes of the two diodes, while the upper circle was the cathode, connected to the substrate. Note that this die is much less complex than even a basic integrated circuit.

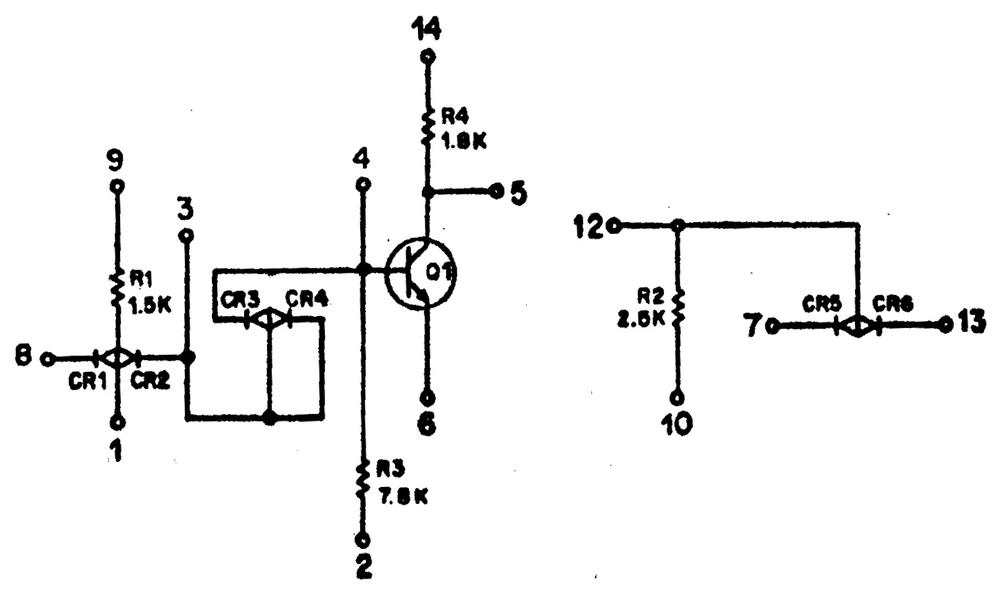

The schematic below shows the circuitry inside the "INV" module shown earlier.7 The left side forms an AND-OR-INVERT gate with a single input. A gate with a single input may seem pointless, but additional AND inputs can be attached to pin 1 and additional OR gates can be attached to pin 3. The right side of the schematic provides components that can be used as additional inputs.

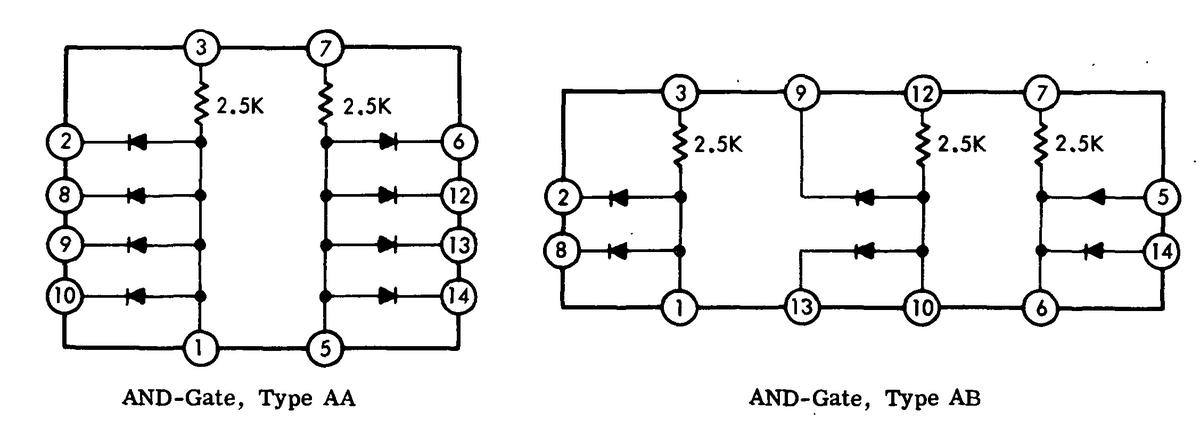

The board also uses AND gate modules (types "AA" and "AB"), shown below. Keep in mind that these aren't independent gates, but components that can be wired to an INV chip to provide more AND or OR inputs.6 These modules can be wired up in many flexible ways; there are no specific inputs and outputs. One common configuration is to use half of an AA chip as a three-input AND gate. Part of an AB chip can provide two more inputs if needed.

The photo below shows the semiconductors (dual diodes) inside an AA gate. You can match up the components with the schematic above if you wish; pins 1 and 5, the common pins, are most interesting. Note that the pin numbering does not match the standard IC scheme.

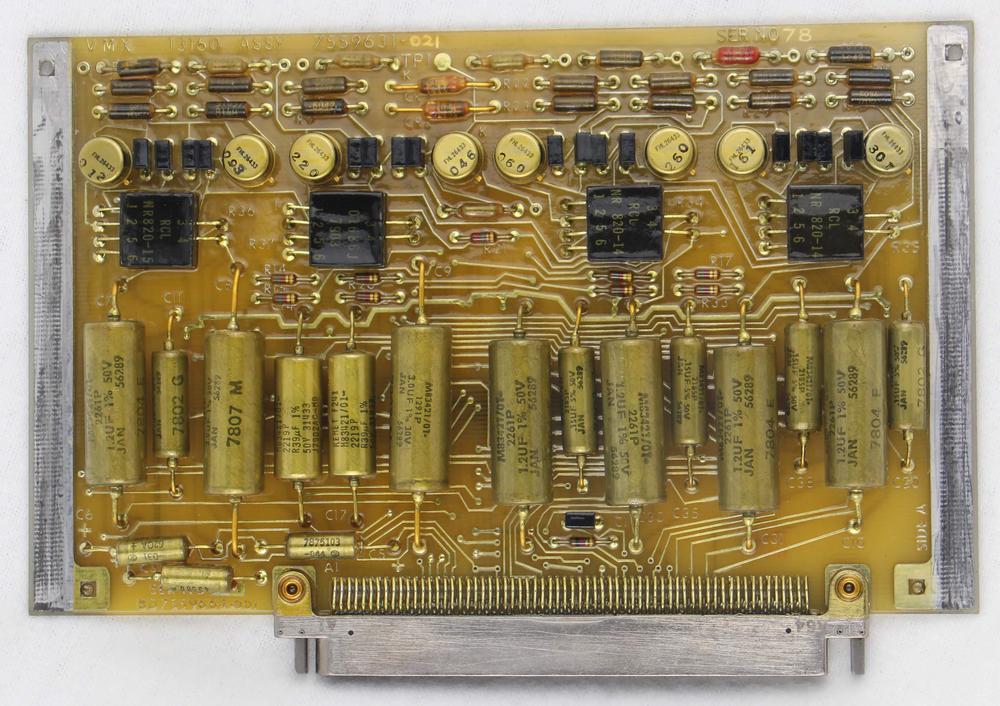

The board's circuitry

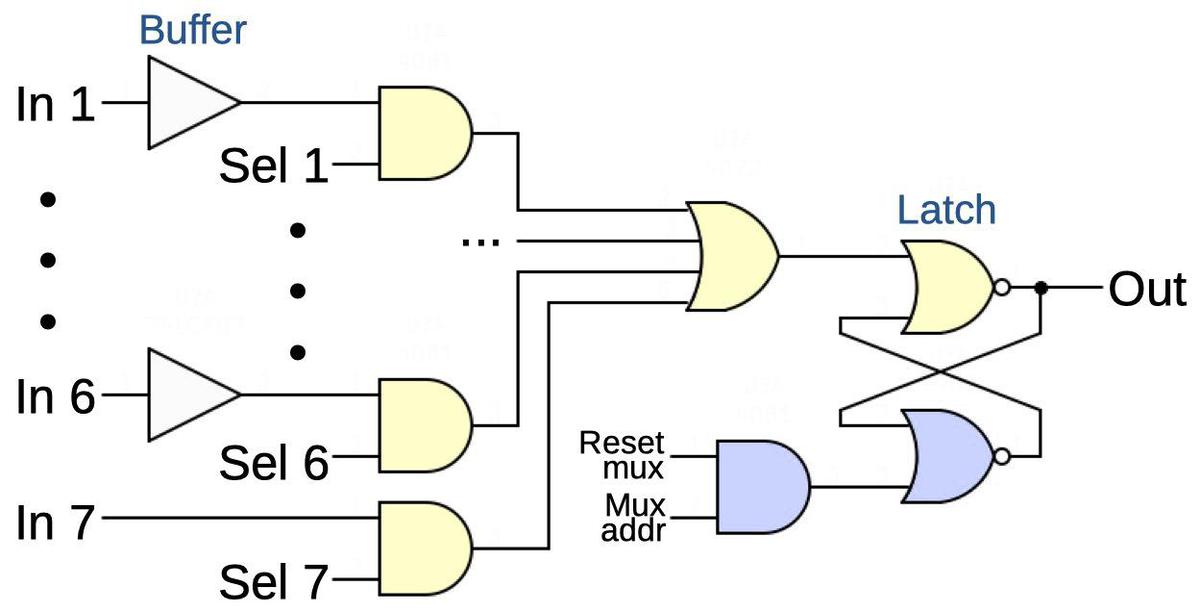

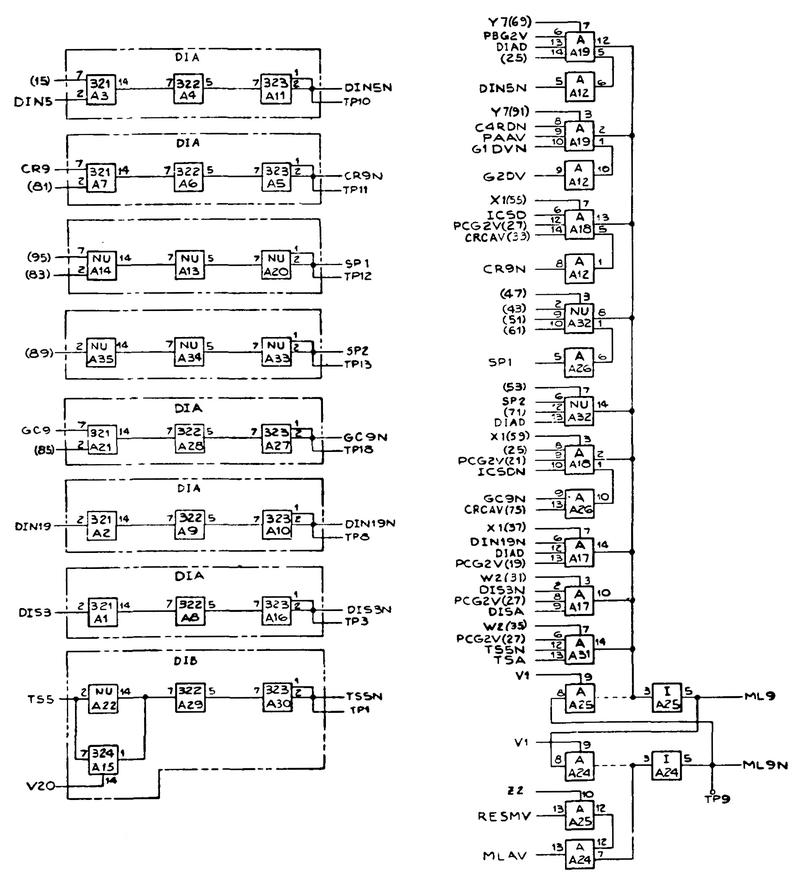

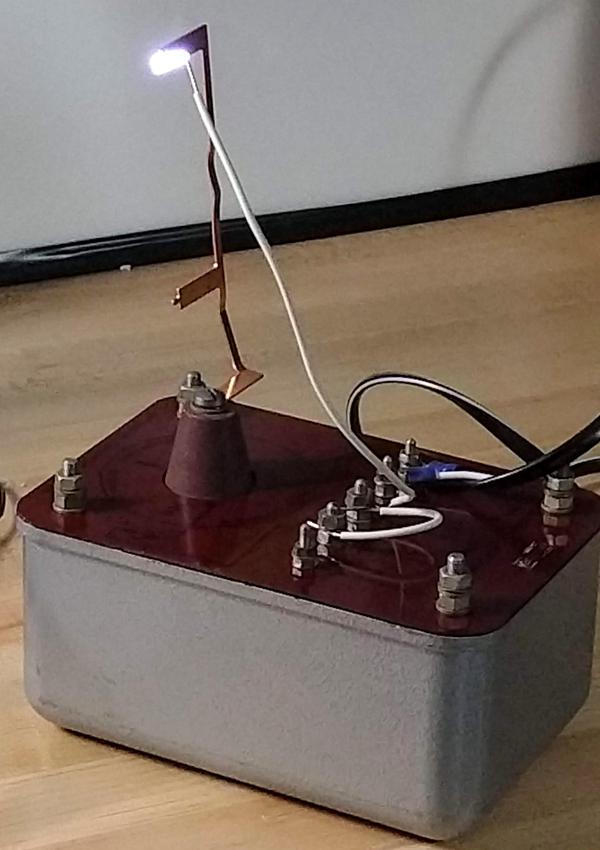

To determine what the board did, I tediously beeped out the connections between chips with a multimeter to create wiring diagrams. (Shortly after I finished, LVDA manuals with schematics turned up8 making my reverse-engineering effort unnecessary.) The board forms a 7-input multiplexer, selecting one of 7 input lines and storing the value in a latch. With 1960s technology, this simple function required a whole board of chips.

The schematic below is a simplified diagram of the board. At the left, the board receives 7 inputs; six of them are 28-volt signals that need to be buffered to generate logic signals, while the seventh is already a 6-volt logic signal. One of the seven select lines is energized to select the corresponding input, which is then stored in the latch.9 (The main simplification is that there are multiple select lines for each input. The full schematic is in the footnotes.10) When the "reset multiplexer" signal and the "multiplexer address" are energized, the latch is reset.

While the schematic shows many logic gates, it is implemented with just two AND-OR-INVERT gates. The yellow gates form one large AND-OR-INVERT gate, while the blue gates form a second. (The two yellow OR gates merge into one.) The two gates are implemented across eight chips: two chips of type INV, four AA, and two AB. This illustrates the flexibility and expandability of the AND-OR-INVERT logic model, but it also shows that circuits use many chips. Note that there are only two transistors in the logic circuit (one in each INV chip); almost all of the logic is implemented with diodes.

The buffer circuitry

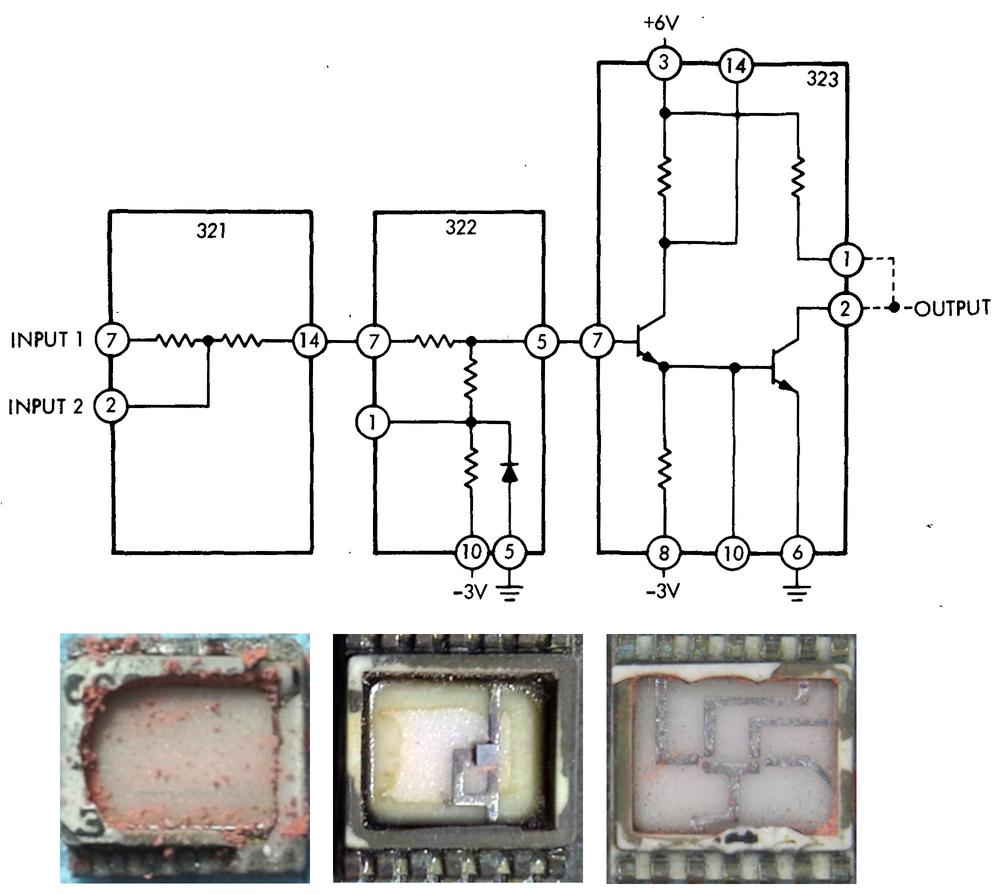

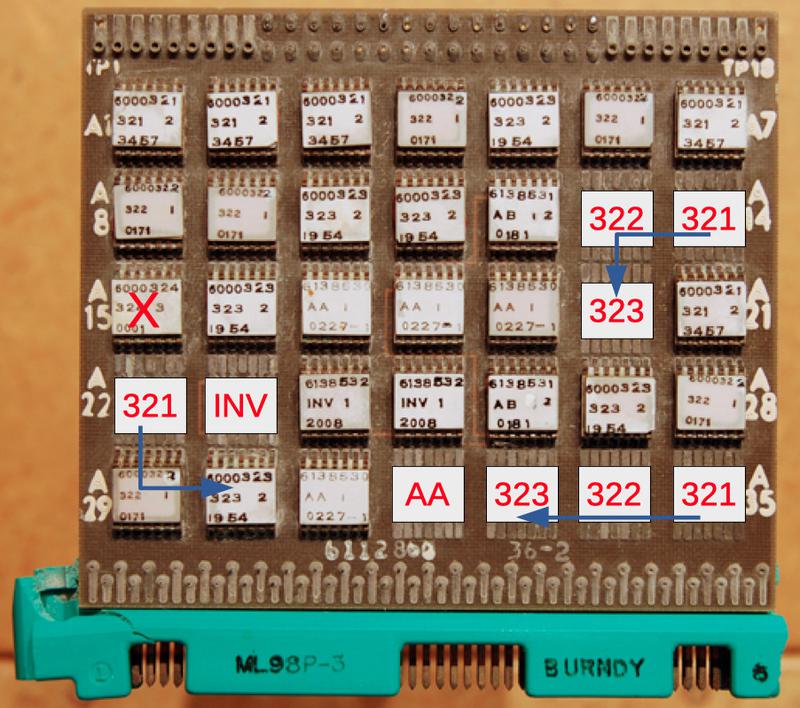

Of the 26 chips on the board, 18 of them were analog chips that buffered and processed the input signals. The inputs were 28-volt signals, while the logic requires 6-volt signals. Each input (except #7) passes through a "Discrete Interface Circuit" that converts the input to a logic signal. The diagram below shows the circuit, built from chips of types 321, 322, and 323.11 The photos show the contents of each chip. Since the 321 chip only consists of resistors (on the underside), the chip appears empty from the top. The 322 chip contains a single diode, while the 323 chip contains two transistors. (The dies are missing from the 323 photo; they are small squares as in the 322.)

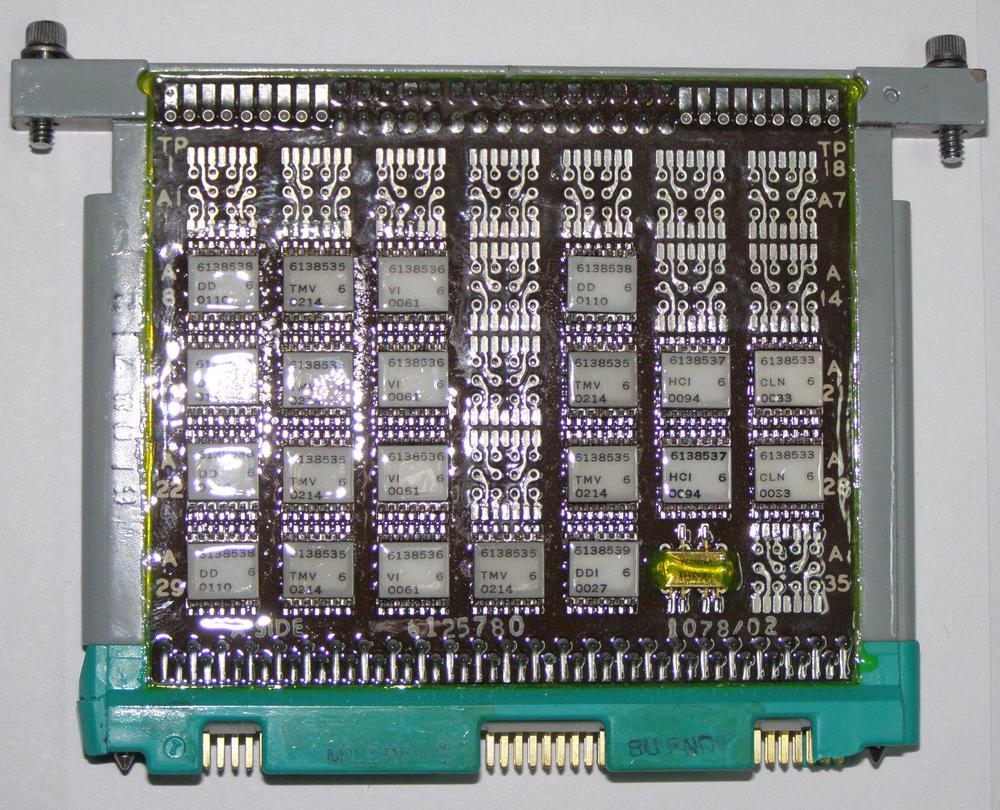

The diagram below summarizes the structure of the board. The eight logic chips in the middle are outlined in green. Each of the six input buffers consists of three chips (321, 322, and 323). The signal flow through these chips is shown with the blue arrows. The board has 35 spots for chips, of which 26 were used. By putting chips in the empty locations, the same circuit board could be reused for slightly different functions.13

The board's role in the LVDA

This board was part of the multiplexer in an LVDA subsystem called the "System Data Sampler" that selects signals and sends them either to the computer or to the ground for telemetry. The System Data Sampler consists of a multiplexer that selects one of eight signals, and the Serializer-Selector that converts the 14-bit data to serial form. The multiplexer has several data sources: the RCA-110 ground computer that was connected to the rocket before launch;14 the "command receiver" that received computer commands from the ground after the rocket had launched; the "control distributor" box that provided various discrete signals;12 "spare discrete inputs"; feedback from the "switch selector", a relay box that the computer used to control the rocket; telemetry from the Digital Data Acquisition System (DDAS); and real-time data.

Physically, many of these data sources were large boxes in the Instrument Unit. For instance, the "control distributor" was a 35-pound box next to the LVDA, connected by a thick cable. The LVDA's "command receiver" input came from the "command decoder", a 7.5-pound box connected to other boxes that provided radio input and output. Because the LVDA was cabled to many different devices in the Instrumentation Unit, it required 21 connectors.

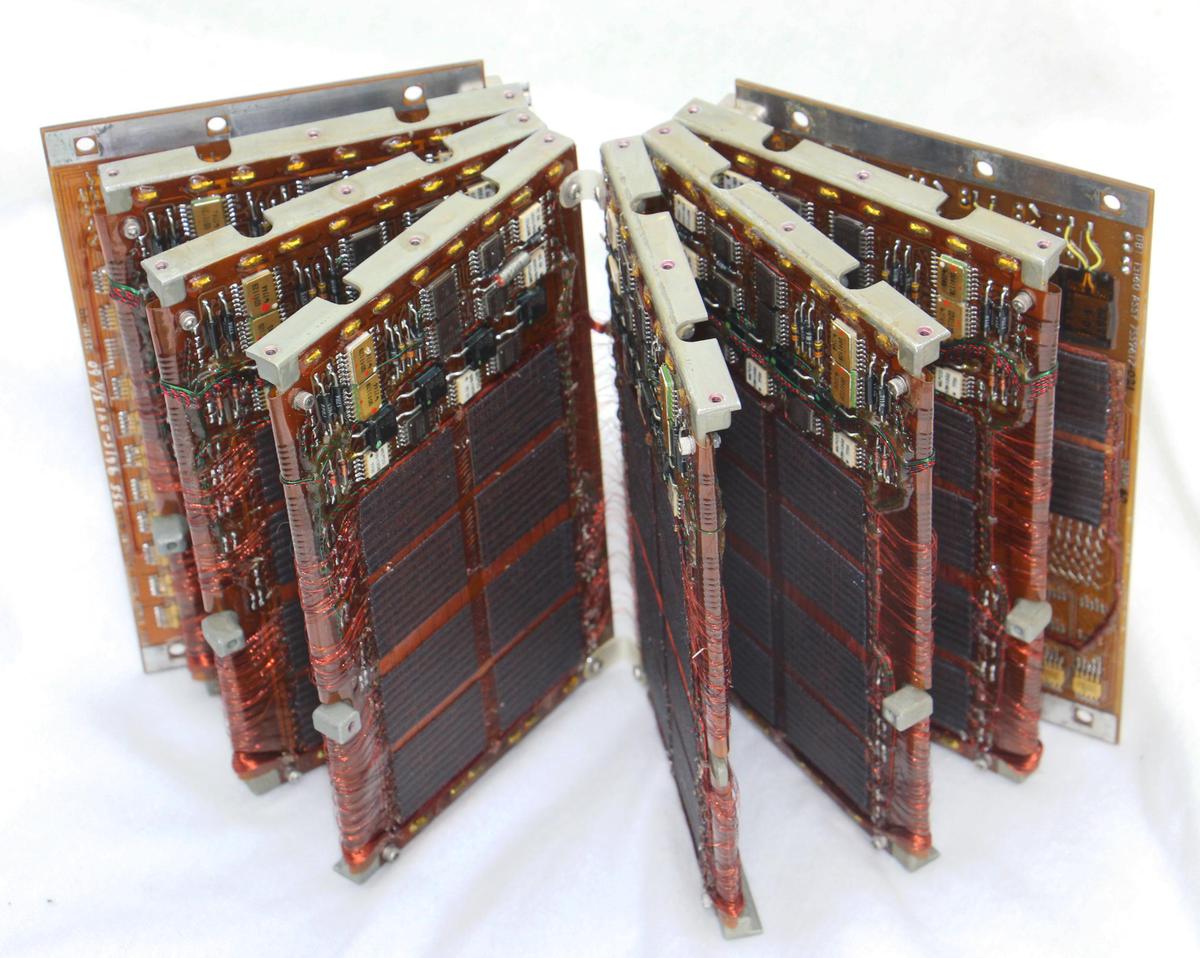

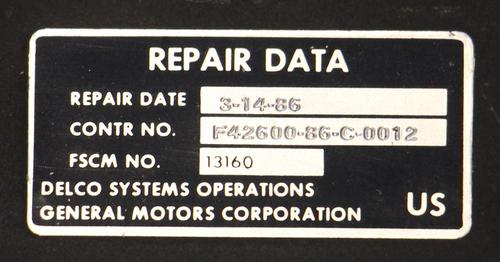

The board's physical structure

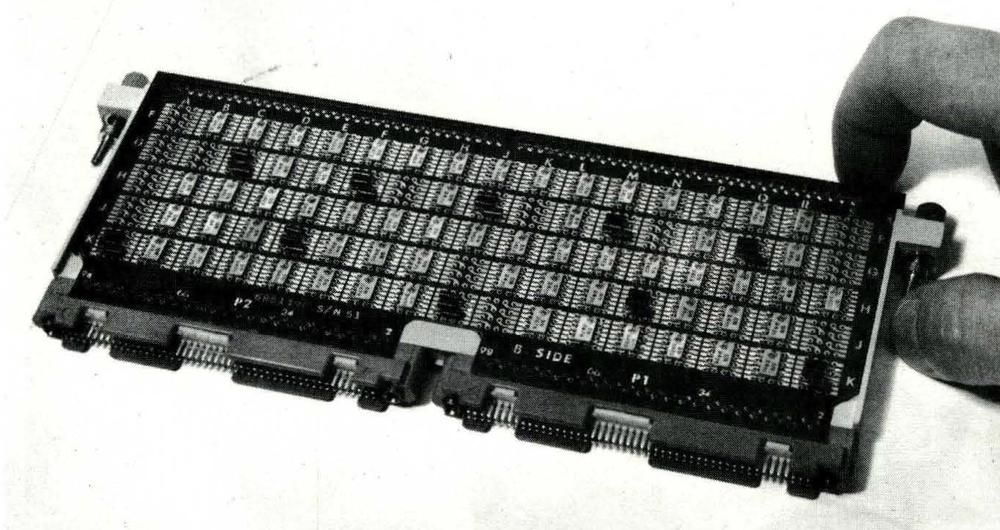

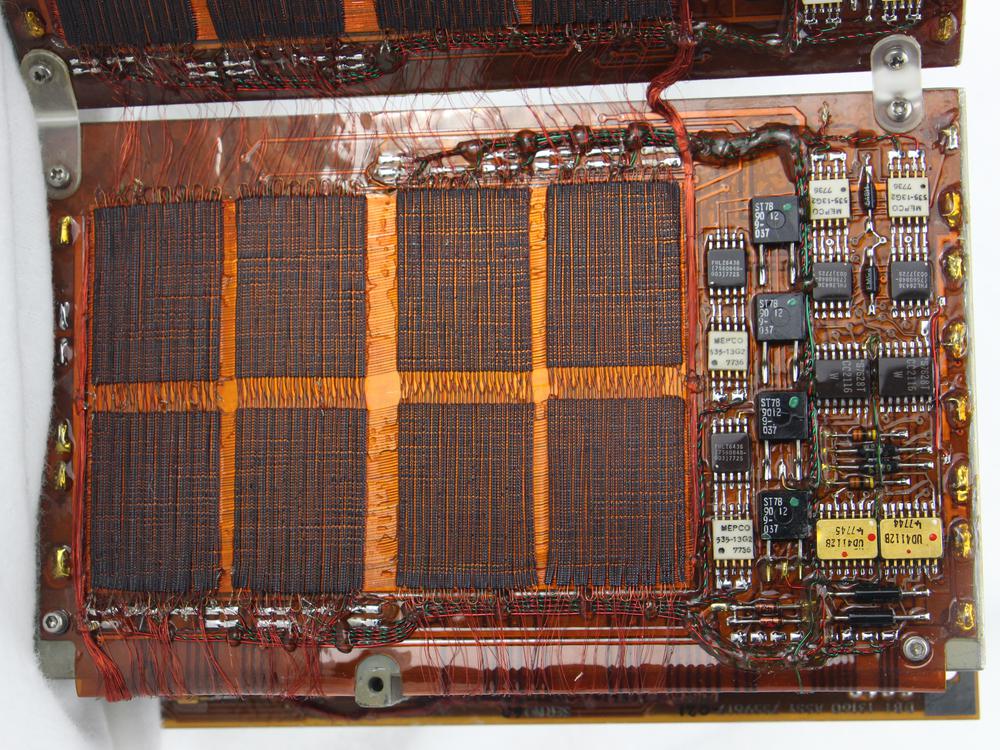

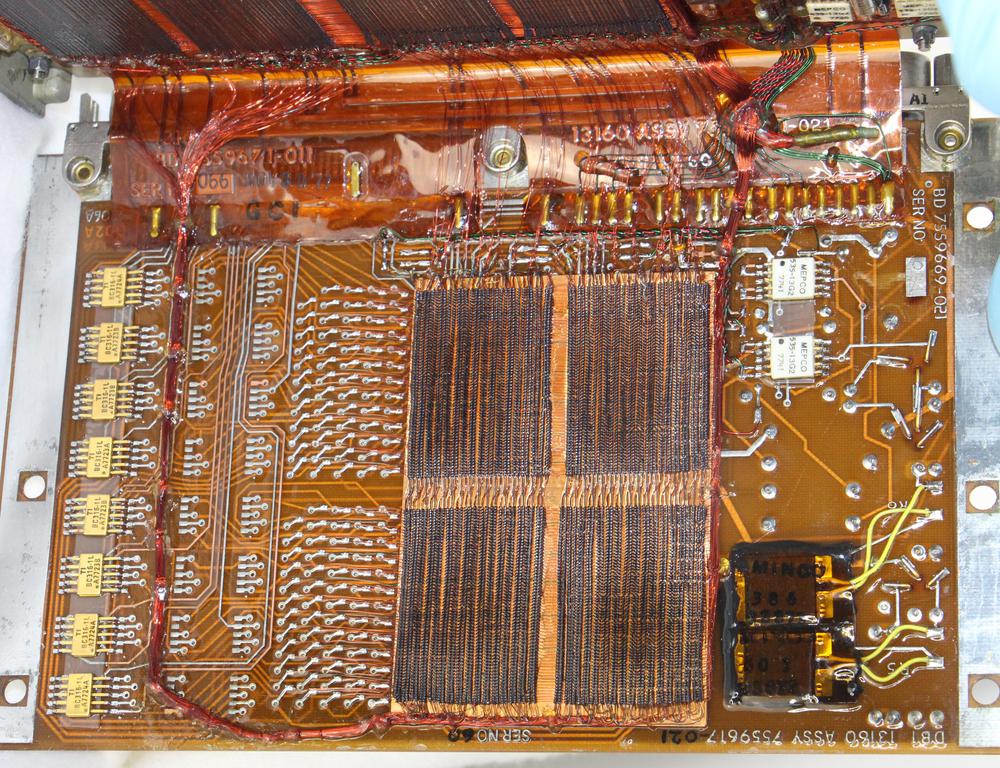

The circuit boards in the LVDA and LVDC used interesting construction techniques to withstand the high accelerations and vibrations of the rocket and to keep the circuitry cool. The board I examined was damaged and missing its mounting frame but the photo below shows an intact unit called a "page". The page's frame is made from a magnesium-lithium alloy that combines light weight, strength, and good heat transfer properties. Heat from a board flowed through the frame to the LVDA or LVDC's chassis, which was liquid-cooled via methanol flowing through channels drilled in the chassis.

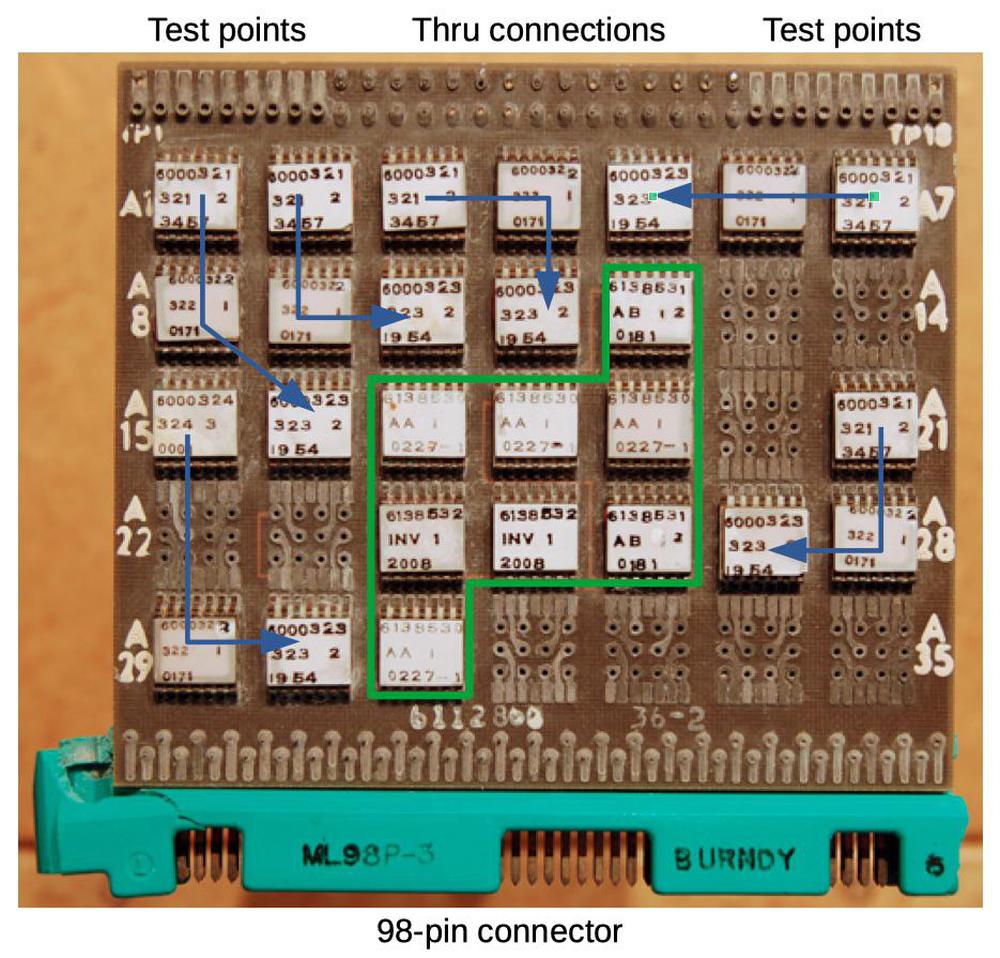

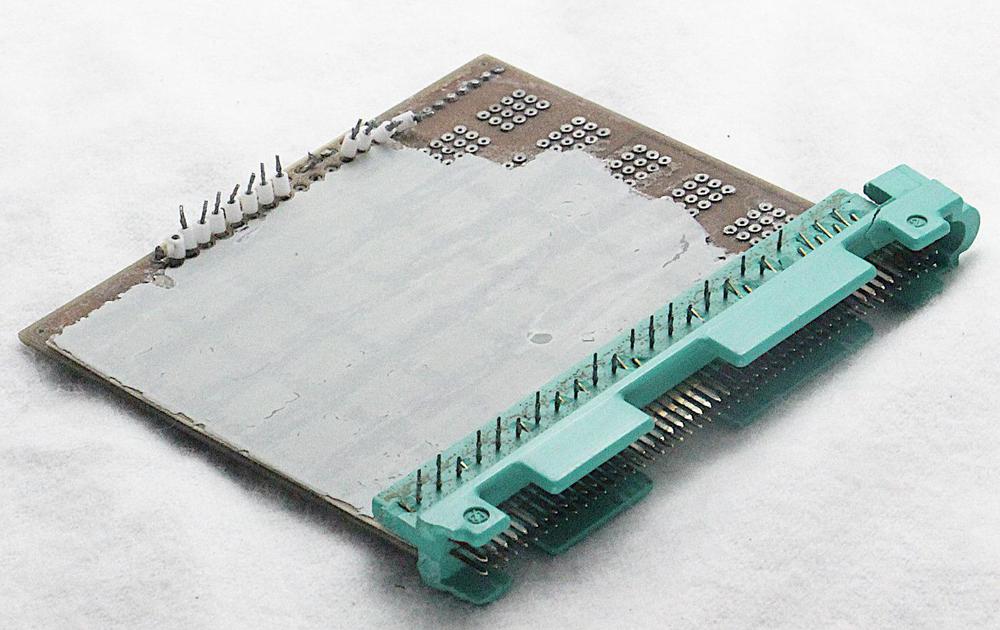

Each page could hold two circuit boards, one on the front and one on the back. The printed circuit board has 12 layers, which is a remarkably high number for the 1960s. (Even in the 1970s, commercial PCBs typically had just two layers.) The page has a 98-pin connector, with 49 connections to each PCB. The two boards were connected by 30 "thru pins" at the top of the board. The top of each board also has 18 test connections; these allowed signals to be probed while the boards were installed. (IBM reused this page construction in its System/4 Pi aerospace computers.15)

The board I examined had been forcibly separated from the other board in the page. The photo below shows the back of the board. The thru-pins are visible at the top; they would have been connected to the other board. At the bottom, the 49 connections from the connector to the missing board are visible. Some of the board's insulation has been removed, showing the 12 vias at each ULD module position. These provide a connection from a chip pin to any of the 12 layers of the circuit board.

Conclusion

This small circuit board illustrates several stories about computing in the 1960s.

The board used hybrid modules rather than still-new integrated circuits. While this technology may seem backward, it was a key to IBM's success with the IBM System/360 line. Introduced almost exactly 56 years ago (April 7, 1964), these computers used hybrid SLT modules with AND-OR-INVERT logic. These computers dominated the market for years, and the System/360 architecture is still supported by IBM's mainframes.

The LVDC and LVDA also led to IBM's System/4 Pi line of aerospace computers, announced in 1967. These computers used the same "page" design and connectors as this board, even though they abandoned ULD modules for flat-pack TTL integrated circuits. The System/4 Pi line of computers evolved into the AP-101S computers used on the Space Shuttle.

Finally, the board shows the remarkable improvements in technology since the 1960s. Each ULD module contained up to 4 transistors, so even a basic circuit like a multiplexer took a whole board of modules. Now, an iPhone processor has over 8 billion transistors. It's amazing that such simple technology was enough to get to the Moon.

I announce my latest blog posts on Twitter, so follow me @kenshirriff for future articles. I also have an RSS feed. This work builds on Fran Blanche's Apollo Saturn V LVDC Project. Thanks to Fran for providing photos, Ben Krasnow for passing the board along to me, and Mike Stewart for documentation. For more information on the LVDC, see the Virtual AGC project's LVDC page. I recently wrote about the core memory stack in the Saturn V LVDC.

Notes and references

-

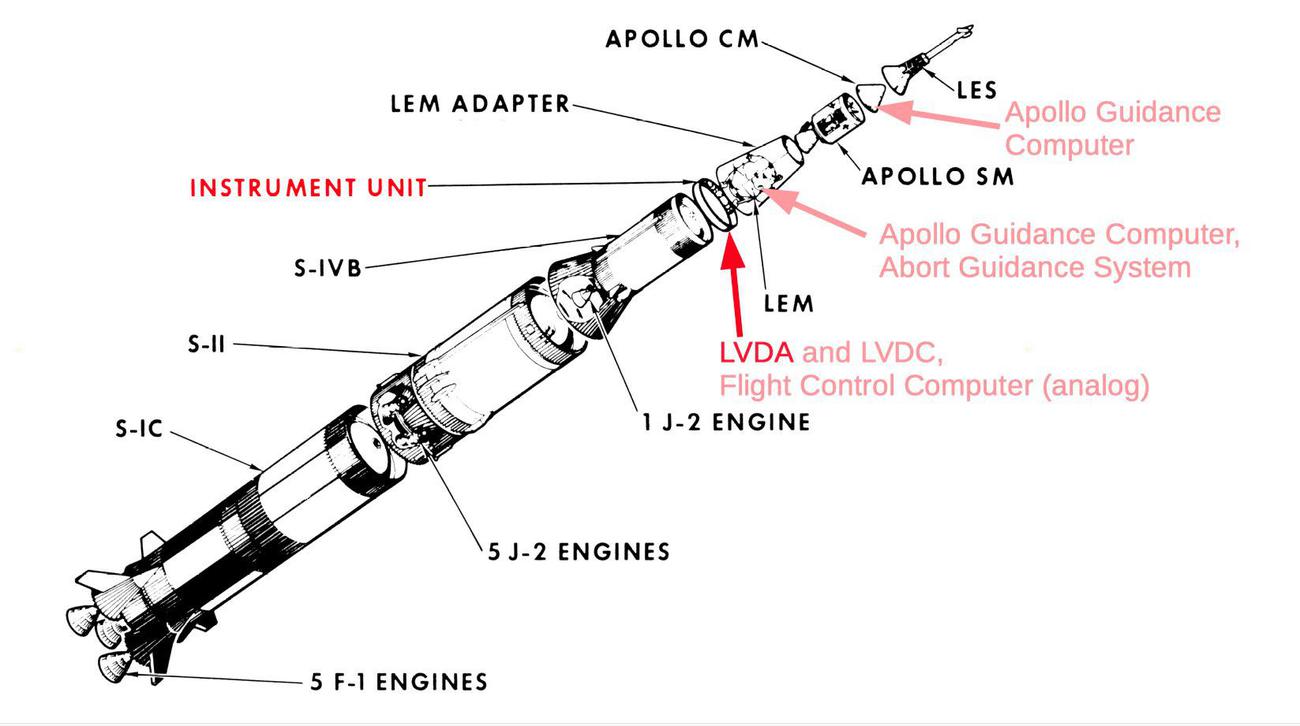

The LVDC was one of several computers onboard the Apollo mission. The better-known Apollo Guidance Computer (AGC) guided the spacecraft to the Moon's surface. (I recently helped restore an Apollo Guidance Computer to running condition.) The Command Module had an AGC while the Lunar Module had a second AGC. The Lunar Module also contained the backup Abort Guidance System computer. The LVDC/LVDA was connected to the Flight Control Computer, a 100-pound analog computer mounted in the Instrument Unit.

Multiple computers were onboard an Apollo mission. The Launch Vehicle Data Adapter (LVDA) is discussed in this blog post.The LVDA and LVDC were mounted in the rocket's Instrument Unit, a ring between the rocket stages and the payload, the Apollo spacecraft. The Instrument Unit contained the guidance and control systems for the Saturn V rocket as well as extensive telemetry systems sending hundreds of parameters to the ground.

The Saturn V Instrument Unit under construction. The LVDC (Launch Vehicle Digital Computer) and LVDA (Launch Vehicle Data Adapter) are silver boxes. For scale, note the engineer sitting on the left. Photo from NASA. -

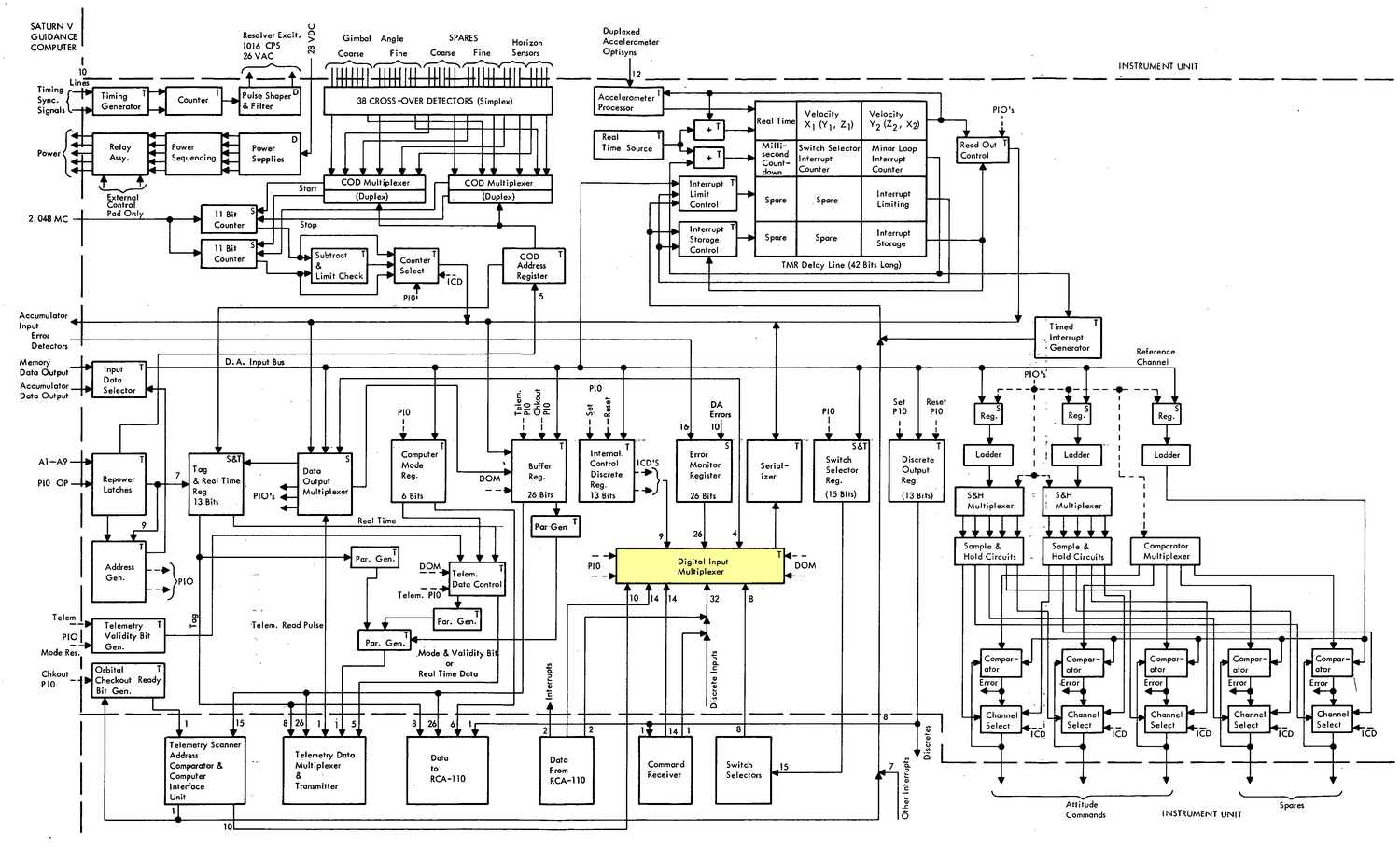

The detailed block diagram of the LVDA below is from the IBM Study Report. (Click the image for a larger version.) This diagram shows that the LVDA has many different functions, registers, and circuits, with many connections to the LVDC (left) and the Instrument Unit (top and bottom). The board I examined is part of the "Digital Input Multiplexer", highlighted in yellow. Note the various data sources feeding into the multiplexer.

Block diagram from IBM Study Report. -

IBM's use of diode-based AND-OR logic goes back to vacuum tube computers from the 1950s. The large 700-series computers primarily used AND-OR diode networks for their logic, with vacuum tubes for amplification instead of transistors. The photo below shows an 8-tube module. Note the large number of diodes (black components with white stripes) in the module below. I think the role of semiconductor diodes is largely ignored in the era of vacuum tube computers. The IBM 709, for instance, used 2000 vacuum tubes and 14,500 diodes in its arithmetic unit.

Tube module from an IBM 700-series computer in the 1950s. Note the many diodes, especially in the lower left. -

One unusual feature of the LVDC's gates is that the pull-up resistor often isn't connected to the positive voltage source, as you'd expect. Instead, it is connected to a clock signal. When the clock is high, the AND gate functions normally, but when the clock is low, the AND gate is disabled. This has two benefits. First, the pull-up acts as an additional input, ANDing the clock into the result. Second, this reduces power consumption, since there is no current through the pull-up resistor when the clock is low. ↩

-

Dr. Wernher von Braun wrote an interesting article about the use of ULD modules for Apollo: Tiny Computers Steer Mightiest Rockets (Popular Science, Oct 1965). ↩

-

The ULD logic chips exist in a liminal space, a transition between individual components and integrated circuits. They are not arbitrary components, but neither are they logic gates with defined functions. Instead, they are sets of components that can be pieced together into gates in flexible ways. ↩

-

While the ULD chips have 14 pins, the numbering doesn't match normal 14-pin integrated circuits. The top contacts are numbered 1 through 7 (left to right), and the bottom contacts are 8 through 14 (left to right). (Note that The Apollo Saturn V LVDC Project does not use the IBM numbering.) In addition, the circuit board can only use 12 of the pins because of the 12 vias at each position; contacts 4 and 11 (the middle ones) are not connected. ↩

-

There is very little documentation available for the LVDC and even less for the LVDA. The Virtual AGC document library is the best source that I found. In particular, the strangely-named "Laboratory Maintenance Instructions for LVDC" volume 1 and volume 2 provide detailed explanations and schematics. The recently-uncovered "Laboratory Maintenance Instructions for LVDA" volume 1 and volume 2 provide similar detail for the LVDA. The System Description and Component Data has photos of the Instrument Unit components and brief descriptions. The Saturn V Flight Manual discusses the LVDC and LVDA at a high level. The IBM Apollo Study Report has more high-level information on the LVDC and LVDA and some nice diagrams. To get more information the LVDC and LVDA, I'll need to visit the US Space and Rocket Center in Huntsville, Alabama, but currently travel is off the table. ↩

-

The latch is a circuit to store a single bit; it is a standard SR NOR latch, built by cross-coupling two NOR gates. ↩

-

The schematic for the board is below. (Click for full-size.) Each box corresponds to a logic element, part of a chip. The top line "A", "I" shows the element type (AND, INVERT) while the bottom line ("A31") shows the chip position on the board. ("NU" indicates "Not Used"; the board is wired with the circuitry but the chip is not installed.) The left side of the schematic is the input buffers, while the right side is the logic.

Schematic of the board. From Laboratory Maintenance Instructions for LVDA, Volume II, page 10-114. -

Most of the chips in the LVDA/LVDC have descriptive alphabetic codes such as INV (invert), DLD (delay line driver), or ED (error detector). However, the analog chips on the board have numbers instead: 321, 322, 323, and 324. It looks like instead of coming up with descriptive names for these chips, they just took the last three digits of the part number, e.g. "323" has part number "6000323". I also noticed that on the 6000322 parts, the last "2" has been retouched on the chips; I'm not sure what significance that has. ↩

-

The "discretes", the binary inputs to the LVDA/LVDC, consisted of high-level signals such as "Liftoff", "S-IB Outboard Engine Out", "S-IVB Engine Manual Cutoff", or "S-IB Stage Separation". I was surprised that the hundreds of measurements throughout the rocket are ignored by the computer; it only cares about the major state transitions such as the engine stopping and a stage separating. (As well as the inertial guidance data, which was key to the computer's navigation.) ↩

-

The board has nine empty positions where modules aren't installed, but these positions are wired into the circuitry. The purpose of this is that the same circuit board can be used for multiple functions based on which chips are installed. Specifically, the multiplexer used 13 boards of which 4 were identical to the one I examined, 8 had a few different chips, and 1 was entirely different. The reason for this is that the multiplexer was 14 bits wide, while the inputs were of varying widths. For instance, there were 8 Discrete Input Spares and 10 Telemetry Scanner bits. Thus, some of the boards didn't use some of the inputs and those chips could be omitted, saving a small amount of weight and cost. The diagram below shows the missing chips that can be added.13

The circuit board with the missing chips filled in. The chip with an X could be replaced by the 321 below it. Original photo courtesy of Fran Blanche.The board had two unused inputs; to use these, additional 321/322/323 chips were installed. The board also had one input wired up so it could use either a 324 input chip (as in the board I examined) or a 321 input chip. The 321 chip was used for a discrete input that used standard 28-volt signaling, while the 324 chip was used for a signal that was either grounded or floating. The 324 chip included a diode and pull-up resistors. By putting the necessary chip in the appropriate spot, the same PCB could be used for either type of input.

Two of the boards included an extra logic gate separate from the multiplexer (the INV and AA chips). These gates generated the signals to switch the command input between the RCA-110 mainframe when on the ground, and the radio command decoder after liftoff. In other words, when the umbilical cable pulled out of the Instrument Unit during launch, the signal ("ICS") from the ground computer was lost. Through these two gates, the multiplexer switched the command input from the ground computer to the command decoder, enabling radio commands for the LVDC. ↩↩

-

The RCA-110A computer that communicated with the rocket was in the mobile launch platform, complete with card reader, keypunch, and line printer. In other words, they were moving a whole computer room on the crawler out to the launch pad, with the rocket mounted on top. (In the photo below, the computer room is at the front left of the blue launch platform, under the launcher-umbilical tower.) It communicated with a second RCA-110A computer in the firing room. For details on the mobile launcher and swing arms, see Apollo Maniacs or the book Rocket Ranch. To summarize the wiring, cables went from the RCA-110A computer room near the rocket nozzles, up the tower and across swing arm 7, through the umbilical panel, and to the LVDA. One bit of these signals went to the multiplexer board I examined.

Apollo 11 Saturn V on the mobile platform, July 1, 1969. Swing arm #7 (marked with arrow) is connected to the Instrument Unit and the top of the S-IVB stage. Photo from NASA. -

IBM's 4 Pi series aerospace computers in the 1960s used the same mechanical board structure as the LVDC, with two multi-layer boards mounted on a "page" mounted in a metal frame. The 4 Pi boards were also double-width or triple-wide compared to the LVDC boards, using two or three of the same 98-pin connections. (Compare the board below with the board that I examined.) The circuitry was entirely different though; the 4 Pi boards used flat-pack TTL integrated circuits instead of ULD modules. The 4 Pi architectures and instruction sets were also entirely different from the LVDC. These early 4 Pi systems were used in aircraft such as the A-7E, F-111 and space missions such as Skylab. The 4 Pi series led to the AP-101 computer used on the Space Shuttle.

An IBM 4 Pi page. From Technical Description of IBM System 4 Pi Computers (1967).