My Sonicare electric toothbrush recently quit working, so I took it apart and examined the interesting circuitry inside. There's much more complexity than I expected inside a toothbrush, especially in the mechanism that drives the brush head at 31,000 strokes per minute. Internally, the brush appears to be designed for quality rather than ease of manufacturing. Unfortunately, moisture can get in, causing reliability problems.

The toothbrush is a Sonicare Flexcare Platinum with more features than you'd expect in a toothbrush: three brushing modes, three intensities and a couple timers, along with 10 LEDs to indicate its status. A pressure sensor in the toothbrush changes the vibration if you apply too much pressure while brushing. The toothbrush uses wireless inductive charging so it charges when set on the base. (This toothbrush may seem overly complicated, but it's nothing compared to the new model that includes Bluetooth.)[1]

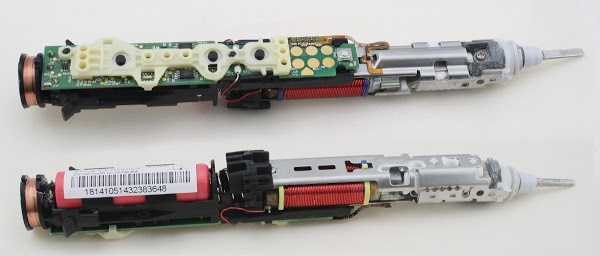

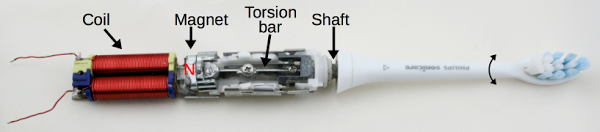

The first step was to remove the toothbrush base, allowing the toothbrush mechanism to be removed from the case. The toothbrush head mounts on the right; it needed to be removed to disassemble the toothbrush. At the left is the charging coil used to wirelessly charge the toothbrush.

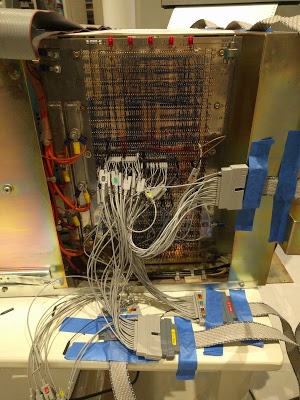

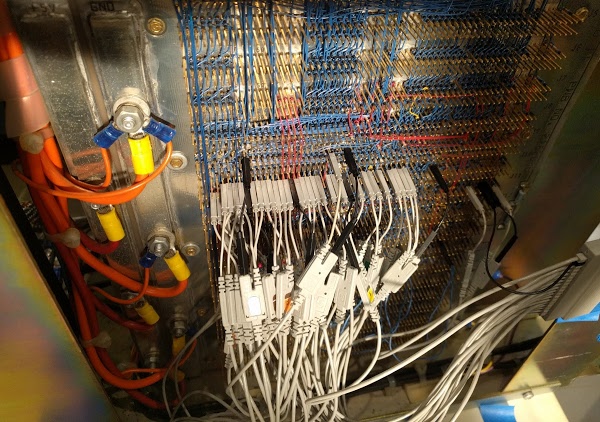

The photos below show the top and bottom of the toothbrush internals. I expected to find a simple, low-cost mechanism, so I was surprised at how much complexity there was inside. The vibration mechanism (right) is built from multiple metal and plastic parts screwed together, requiring more expensive assembly than I expected. The circuit board is literally gold-plated and has a lot of components, even if it doesn't quite reach Apple's level of complexity. Overall, the toothbrush's internal design is high quality (except, of course, for the fact that it quit working, as did an earlier one).

The brush contains several key components, as can be seen above. In the center is the large red coil that causes the toothbrush to vibrate. On the right is the vibration mechanism, which has a powerful magnet that is moved by the coil. The brush head snaps on at the right. The battery (red, left) takes up about a third of the toothbrush. The long, thin circuit board (green) has the circuitry to operate the toothbrush. A white spacer sits on top of the circuit board, with holes for the LEDs and buttons.

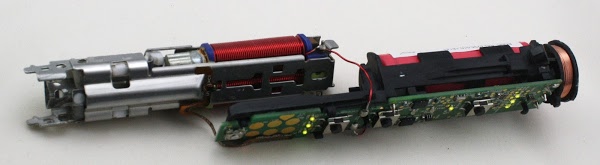

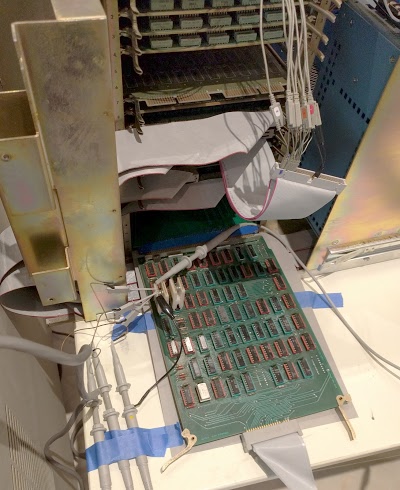

The photo below shows the brush mechanism partially disassembled and separated from the electronics. The toothbrush still powers on in this state, as you can see from the illuminated LEDs. Note the flexible brown ribbon cable between the center of the brush mechanism and the electronics board. This connects the pressure sensor on the brush mechanism to the electronics board.

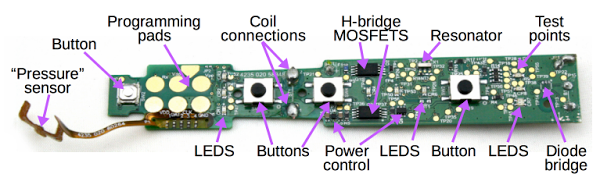

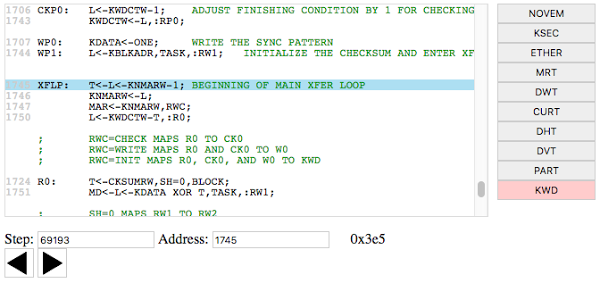

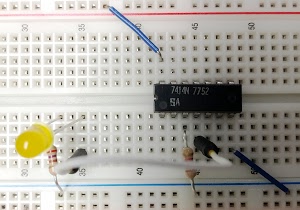

The diagram below shows the main components on the circuit board. The buttons are the most visible feature. The gold circles at the left are used to program the microcontroller. The MOSFET transistor switch the coil on and off to produce vibrations. Ten LEDs are scattered across the board. At the right, the diode bridge is part of the charging circuit.

The circuit board is covered with tiny gold circles. These are test points, allowing test connections to most parts of the board. For instance, each LED and each button has a test point that can be used to test the component. During testing, spring loaded pogo pins on the test circuit make contact with these test points on the toothbrush board. The number of test points (about 56) looks like overkill to me.

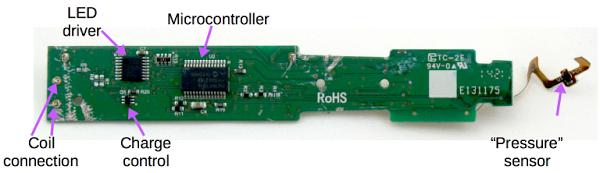

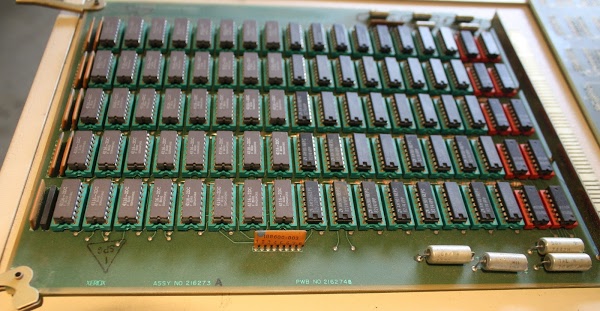

The diagram below shows the components on the back of the circuit board. The toothbrush is controlled by a mid-range 8-bit microcontroller, the PIC16F1516.[2] This chip contains the code for all the toothbrush functions: reading the buttons, lighting the LEDs, controlling the coil, and managing charging. There are too many LEDs (10) for the chip to control individually, so eight of the LEDs are controlled by a separate LED driver chip.[3]

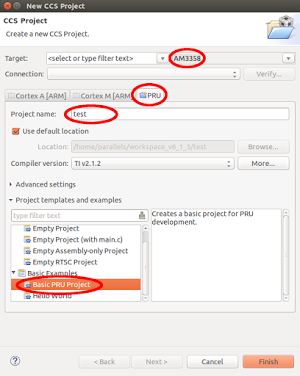

The microcontroller is an off-the-shelf part, not a custom chip, so it needs to be programmed with the right software. This is done during manufacturing through the large gold circles and triangle near the end of the toothbrush.[4] The resonator provides the clock signal for the microcontroller's timing.[5]

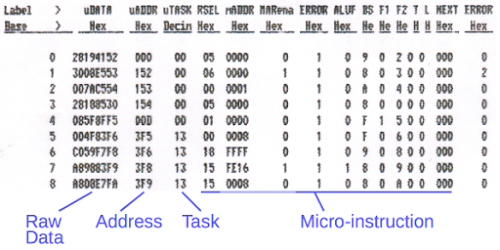

The driver mechanism and the H bridge circuit

The toothbrush head is driven by an electromagnetic coil that moves a magnet. The coil has two halves, wired in opposite directions, so the sides will have opposite magnetic fields. The coil is pulsed one way to rotate the magnet one direction, and then pulsed the opposite way to rotate the magnet the other direction. The result is the high-speed brushing vibration.The diagram below shows the driver mechanism disassembled. The coil constantly switches polarity so the north pole will switch from the top to bottom (the yellow and blue poles of the coil). The magnet has poles on the front and back edges (perpendicular to the coils), so it will attempt to rotate back and forth to line up with the coil, along the long axis of the toothbrush. The mechanism limits the rotation to a few degrees, resulting in a rotational vibration back and forth rather than spinning like a motor. This rotational vibration is transmitted to the toothbrush head by the torsion bar causing the head and bristles to vibrate. More details on the driver mechanism are here.

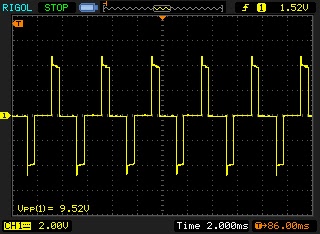

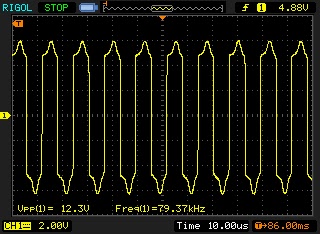

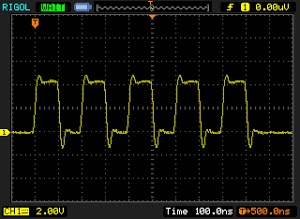

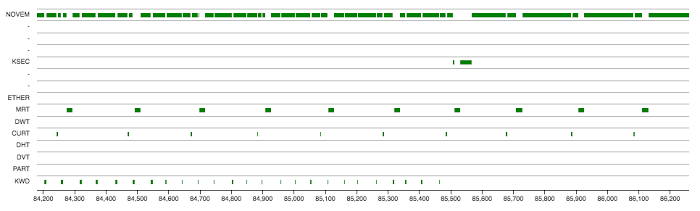

The figure below shows the voltage across the coil. Every 2 milliseconds, there is a 4 volt pulse across the coil, followed by a negative 4 volt pulse. The pulses generate the reversing magnetic field that drives the magnet and causes the toothbrush to vibrate. If you count the positive and negative pulses as separate brush strokes, you get the advertised 31,000 brush strokes per minute. (Although counting an up-down cycle as a single stroke rather than two would make more sense to me.)

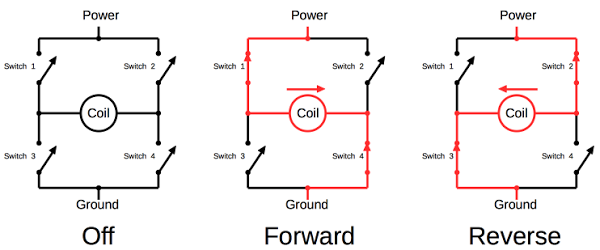

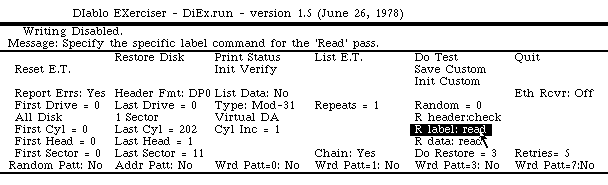

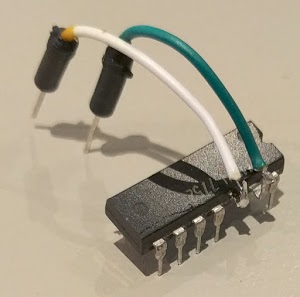

You might think that driving a coil in two directions would use two switches, but instead it uses four, in a common circuit called an H bridge, as shown below. If switches 1 and 4 are closed, current flows in the forward direction. If switches 2 and 3 are closed, current flows in the reverse direction. In the toothbrush, transistors are used for the switches, and are turned on and off by the microcontroller.[6] An H bridge is often used to control motors that need to go forwards and reverse, for example in a hoverboard.

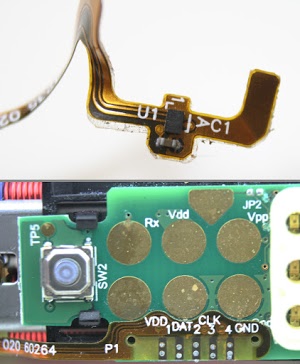

Pressure sensor

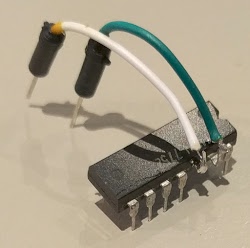

One of the features of this toothbrush is a pressure sensor. If you press too hard while brushing, the vibrations start pulsing and the LEDs flash. The sensor itself is a tiny mystery chip (below) mounted on the drive assembly, and connected to the electronics board with a thin flexible cable. The cable is labeled with Vdd (1), Data (2), Clock (3), and Ground (4), so the sensor is probably sending a stream of bits using an I2C protocol. My suspicion is the sensor is a Hall effect magnetic field sensor that detects a change in the magnetic field if pressure is preventing the magnet from vibrating. The chip doesn't seem to be in a position to measure actual pressure, which is why I suspect it's measuring the magnetic field instead.

Charging

To charge the toothbrush, it is set on a stand and charges inductively without physically being plugged in. A coil in the stand is magnetically coupled to a coil in the toothbrush, transmitting the power wirelessly. You can see the coil at the bottom of the toothbrush. When set on the stand, the coil picks up about 12 volts, which is used to charge the battery. The power is transmitted at high frequency (80kHz) for efficiency.The coil is connected to a diode bridge that converts the power to DC. It then goes through a transistor circuit that regulates the charging, as directed by the microcontroller. The battery in the toothbrush is a Sanyo Li-ion rechargeable battery, which is said to be 3.7V but I measured 4.0V.[7]

The toothbrush is designed to conserve battery by using very little power when not in use. The microcontroller has a low power standby mode when it is waiting for a button press. When the toothbrush is activated, a transistor energizes the LEDs and the LED driver chip, while another circuit powers up the pressure sensor. This prevents these components from draining the battery while the toothbrush is not in use.

Conclusion

Overall, I was surprised by how much electronics was inside the toothbrush, as well as the complexity of the drive mechanism. It was designed with quality in mind, not low-cost production. Unfortunately, the brush has reliability issues—this was the second one to fail on me. The problem appears to be water seeping in around the shaft, eventually damaging the internals.Some other Sonicare teardowns are here, here and here. I would have expected different models to be based on similar electronics that just changed the LEDs, buttons and software. Surprisingly the different teardowns show a variety of microcontrollers, circuitry, and drive coils. Some models even move the magnets from the toothbrush unit to the brush head.

Unfortunately after disassembling my toothbrush I was unable to fix its problem. But at least I got an interesting teardown out of it!

To find out about my latest teardowns, follow kenshirriff on Twitter.

Notes and references

[1] It's ironic for a toothbrush to include Bluetooth technology because Bluetooth is named after Harald Bluetooth, a tenth century Danish king who was called Bluetooth because he had a bad, discolored tooth. The Bluetooth logo itself is formed by combining two runes from the king's name.[2] The PIC microcontroller runs at 16 megahertz. It has 8K of flash memory for the program, as well as 512 bytes of RAM (the RAM on microcontrollers is usually very small) and 128 bytes of flash memory for data. It includes analog-to-digital conversion, which I think is used to monitor the charging voltage. The toothbrush's 8-bit microcontroller is less powerful than the 16-bit microcontroller inside a Macbook power supply.

[3] The LEDs are controlled by a 75HC595A serial to 8-bit output chip. The benefit of this chip is that the microcontroller would use 8 pins to control 8 LEDs, while the microcontroller only uses 3 pins to communicate with the serial chip, freeing up 5 pins for other tasks.

[4] Programming of the chip is done using the ISCP protocol. This uses the programming contacts labeled Vdd, Vpp, Tx, and Ground, as well as the triangle contact, which provides the ISCP data. For some reason, the Tx and Rx circles are also connected to the chips's UART serial pins, allowing serial communication with the microcontroller. I'm not sure why one would want to communicate with the chip outside programming. Maybe there's serial communication with the microcontroller as part of testing. Or maybe the NSA can download information on your brushing habits :-)

[5] The resonator is a 3-pin unit with built-in load capacitors, similar to a quartz crystal oscillator. I suspect it's a CERALOCK®, or something similar.

[6] The H bridge uses a 6866S 20V dual N-channel MOSFET on the low side and a 6963SD 20V dual P-channel MOSFET on the high side.

[7] The charger circuit is puzzlingly simple. The voltage from the diode bridge goes through a microcontroller-controlled transistor (Q5) and then to the battery (through a tiny fuse), without the filtering, voltage regulator or battery voltage monitoring I'd expect. The microcontroller is connected to the AC side of the diode bridge, and presumably is monitoring the input voltage waveform.