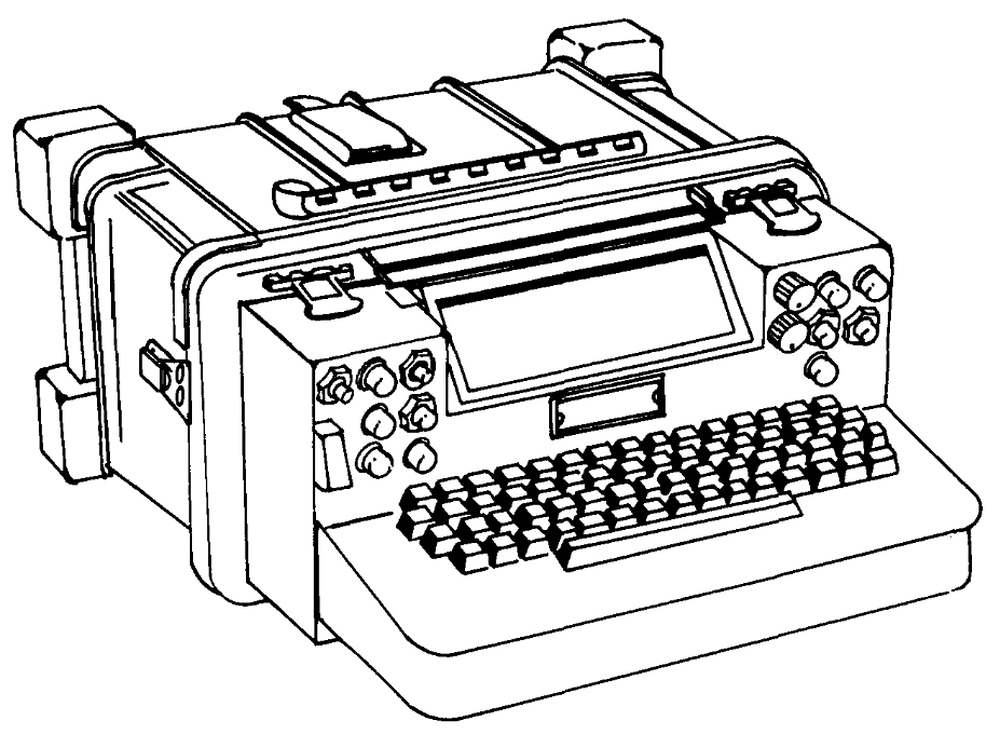

The Space Shuttle contained a bulky printer so the astronauts could receive procedures, mission plans, weather reports, crew activity plans, and other documents. Needed for the first Shuttle launch in 1981, this printer was designed in just 7 months, built around an Army communications terminal. Unlike modern printers, the Shuttle's printer contains a spinning metal drum with raised characters, allowing it to rapidly print a line at a time.

This printer is known as the Space Shuttle Interim Teleprinter System.1 As the name "Interim" suggests, this printer was intended as a stop-gap measure, operating for a few flights until a better printer was operational. However, the teleprinter proved to be more reliable than its replacement, so it remained in use as a backup for over 50 flights, often printing thousands of lines per flight. This didn't come cheap: with a Shuttle flight costing $27,000 per pound, putting the 59-pound teleprinter in space cost over $1.5 million per flight.

We obtained access to a Shuttle teleprinter (probably a development system that remained on the ground) and wanted to put it into operation. I had to reverse engineer three of the boards inside the printer to determine the data format the printer accepted: serial data encoded into audio. But after analyzing the printer and performing a lot of maintenance, we succeeded in getting the printer to print. In this article, I'll describe the Shuttle's Interim Teleprinter, explain its circuitry and drum-based printing mechanism, and show it in operation.

History of the Shuttle's Interim Teleprinter

The motivation for the teleprinter goes back to the Apollo program. During Apollo missions, the only way to send information to the astronauts was by talking to them over the radio and having the astronauts write down the data. NASA decided that the Space Shuttle should include a mechanism to send text and images to the astronauts, a 78-pound, high-tech fax machine called the Uplink Text & Graphics System (TAGS). A high-resolution grayscale image was sent to the Shuttle as a digital data stream. Onboard the Shuttle, a squat CRT displayed the image one line at a time and a fiber-optic faceplate transferred each line to light-sensitive silver emulsion paper. The paper was developed by passing it over a hot roller at 260ºF for 25 seconds, creating a permanent image.

The one flaw in this plan was that sending the digital image to the Shuttle required the Tracking and Data Relay Satellite System (TDRS), which due to delays wouldn't be ready until the sixth Shuttle flight. (The TDRS was a space-based replacement for the worldwide network of ground stations that was used during Apollo.) As a result, NASA decided just seven months before the first Shuttle launch that they needed an interim system "for transmission of real-time, flight-plan changes and other operational data to the crew."2

The Shuttle teleprinter is the result of this rushed effort to create a printer that could work over the existing audio channel rather than the digital TDRS satellite. Due to the time pressure, the Shuttle teleprinter needed to be based on an off-the-shelf printer. Thermal and electrostatic printers were rejected due to toxicity and flammability problems. (The Shuttle teleprinter used a roll of yellowish paper, which required a NASA waiver due to its flammability, a concern ever since the Apollo-1 disaster).

The decision was made to use a military communications terminal, the the AN/UGC-743 "Tactical Teletype". The terminal's interfacing was very flexible, supporting serial data in either ASCII or Baudot format, with multiple configurations and baud rates (up to 1200 baud), using either a current-loop or voltage signals. The military terminal supported two-way communication, so it had a keyboard. Remarkably, the terminal also implemented a word processor, controlled by a Motorola 6800 microprocessor (ancestor of the famous MOS 6502). The word processor allowed messages to be composed offline, minimizing the radio transmission time, which was important in a hostile environment. As will be seen, this 100-pound military system required many large changes to be usable on the Space Shuttle, most visibly removing the keyboard.

The printing mechanism

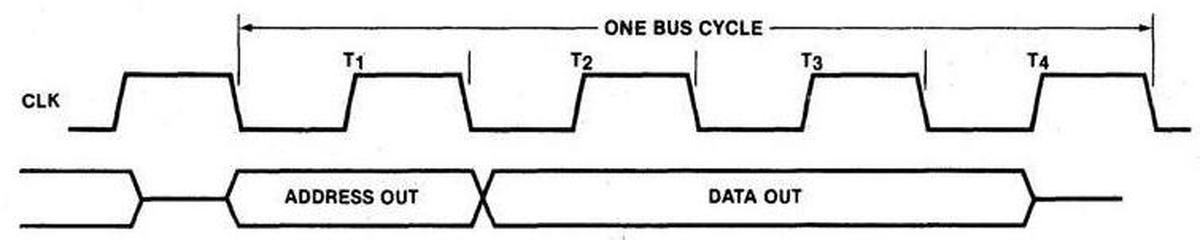

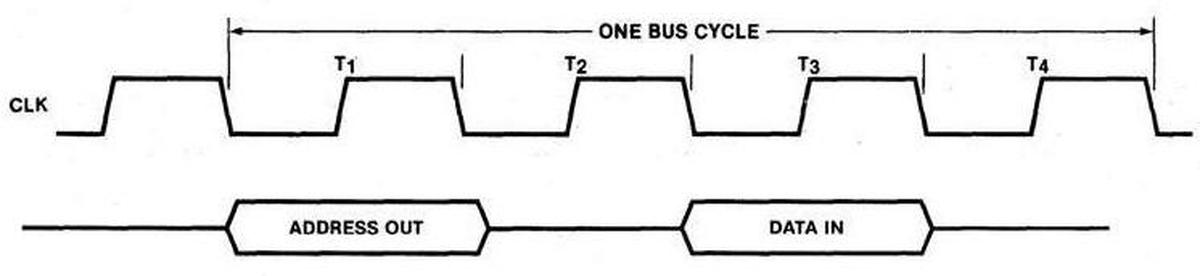

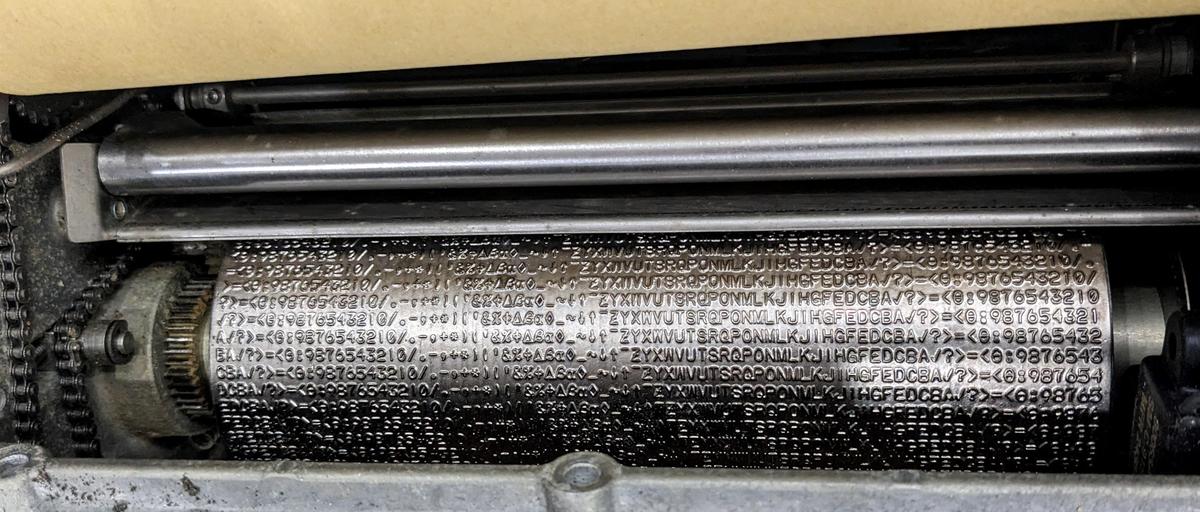

The teleprinter uses a spinning drum with raised characters, shown below.4 To print a character, the printer fires a hammer, forcing the inked ribbon and paper against the raised character on the drum. The drum is 80 characters wide, matching the line length, and there are 80 corresponding hammers, one for each print position. The drum has 64 printable characters, wrapped around each position of the drum.

The printer prints a line at a time, not instantaneously, but during each revolution of the drum. When the drum makes one complete revolution, each of the 64 characters passes by each print position once. Printing requires precise timing of the hammers to strike the right character on the drum as it whizzes by. The printer control circuitry triggers each hammer at the proper time, when the desired character on the drum is lined up with the hammer, producing the desired text.5

The character set is slightly different between the military printer and the Shuttle printer.

The military drum had 64 ASCII characters (upper-case letters only, numbers, and special characters).

The drum doesn't contain an explicit space character, since nothing is printed for a space. In its place, the drum has a diamond "◊", used as a special character to indicate a parity error or

other error.

The drum for the Shuttle teleprinter replaces 10 ASCII special characters with symbols that are more useful to the Shuttle, such as Greek letters for angles.

Specifically, the characters ;@[\]^!"#$ are replaced by θ✓‾↑↓~αβΔϕ.

The video below shows a closeup of the hammers as they strike the paper to print text. The text is the teleprinter's built-in test message: "THE LAZY YELLOW DOG WAS CAUGHT BY THE SLOW RED FOX AS HE LAY SLEEPING IN THE SUN". This test message is based on the traditional quick brown fox..., which is a pangram, containing all 26 letters, but the teleprinter's test sentence is missing J, K, M, Q, and V. However, the test message is exactly 80 characters long and replaces spaces with the diamond "◊", so it is effective for verifying that all 80 columns work.

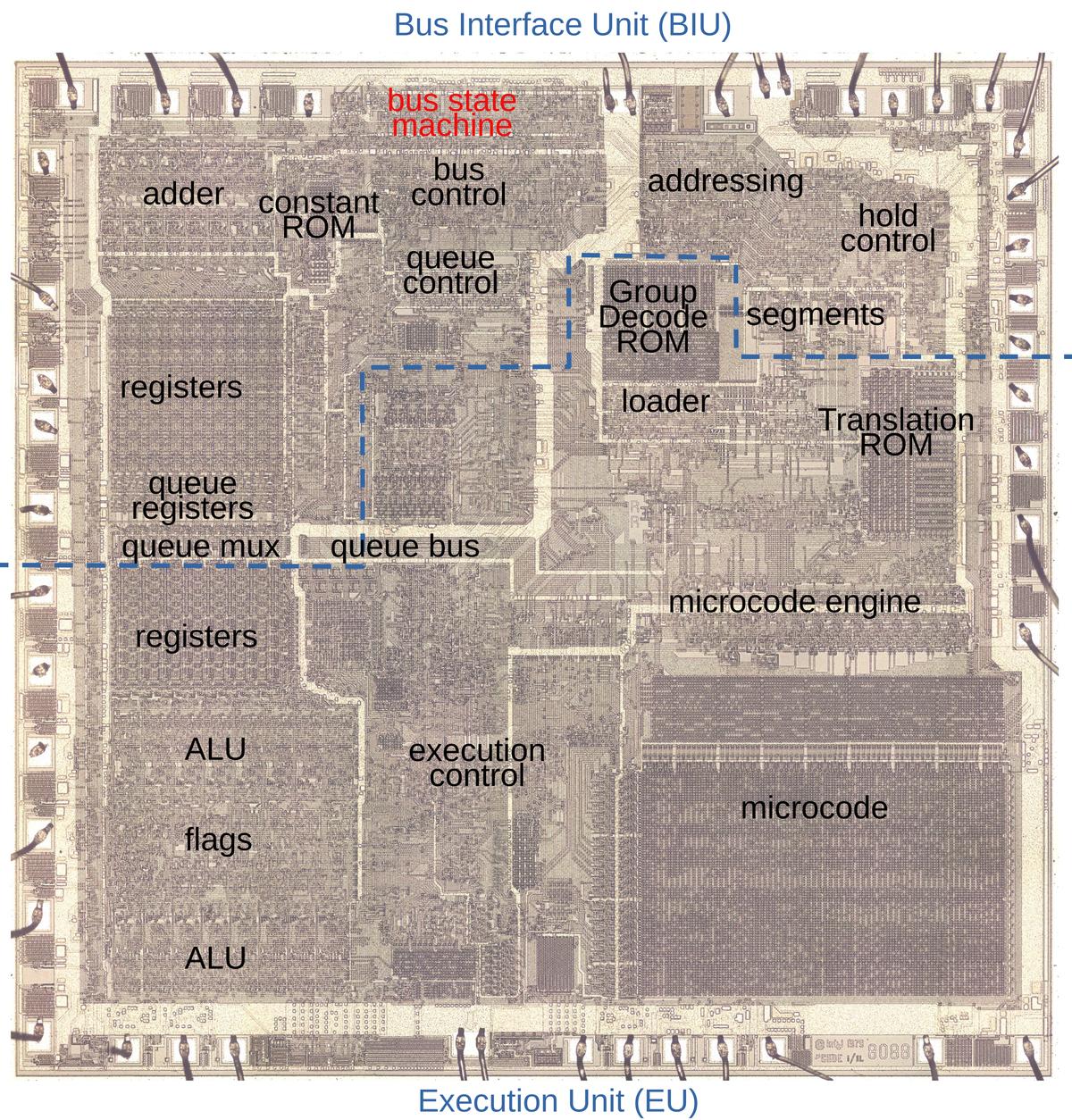

The electronics

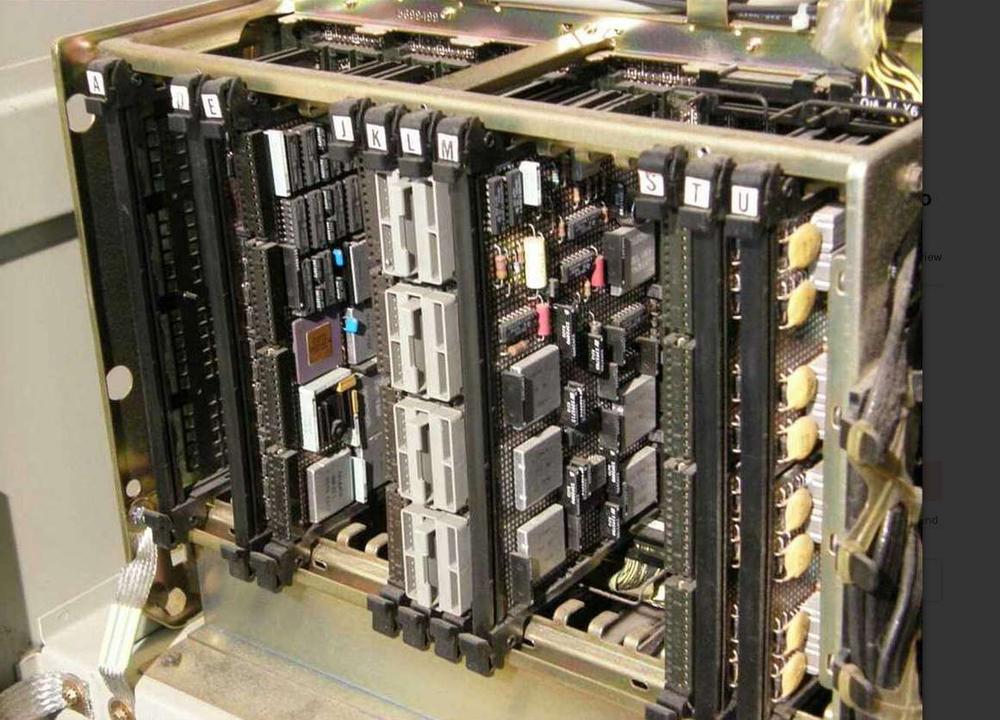

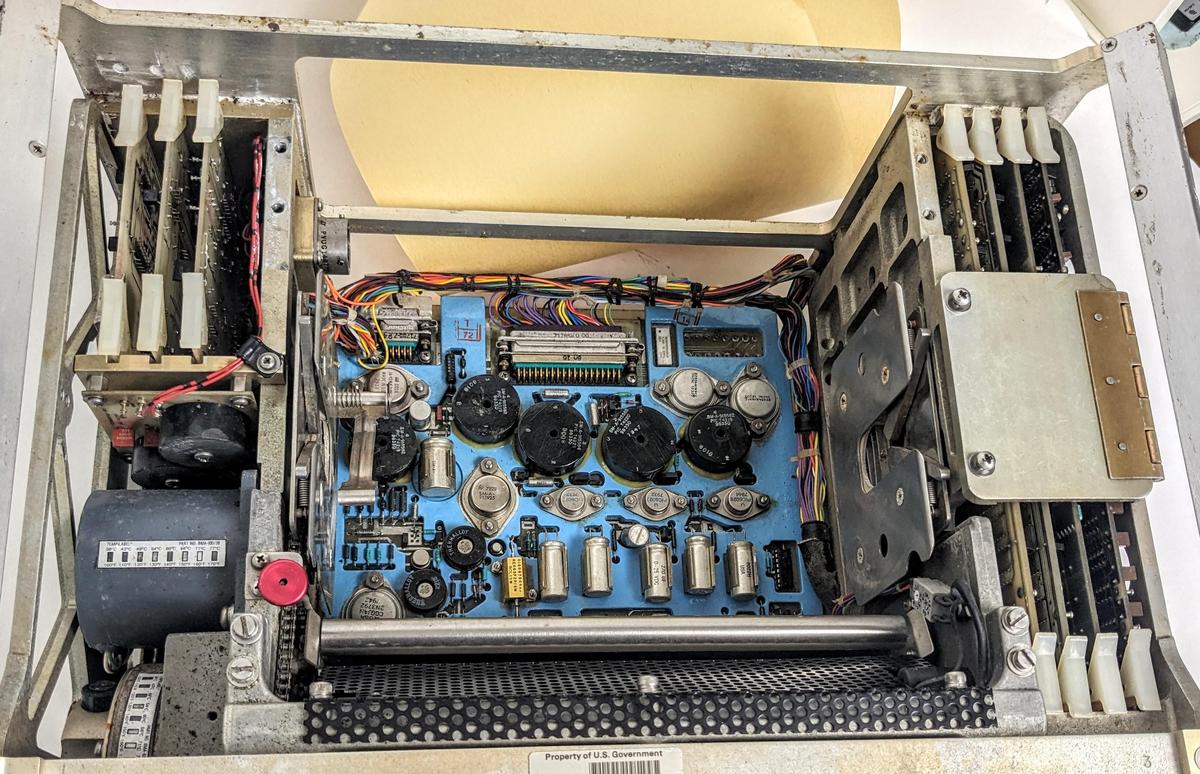

The photo below shows the circuitry inside the teleprinter, looking down from above. At the left are the three interface boards, custom boards that demodulate the incoming audio signal. In front of the interface boards are large inductors to filter the incoming power. Hidden beneath them, a solid-state relay controls the power to the rest of the printer, implementing the low-power standby mode. In the middle, the blue board is the surprisingly complex switching power supply, mounted on a thick metal plate for cooling. Normally, the large roll of paper is mounted above the power supply board. At the right, four large circuit boards implement the main logic of the printer: a printer driver board, a communications board, a memory board, and the processor board. The rotating drum is protected by the perforated black metal grill at the front.

The demodulator boards

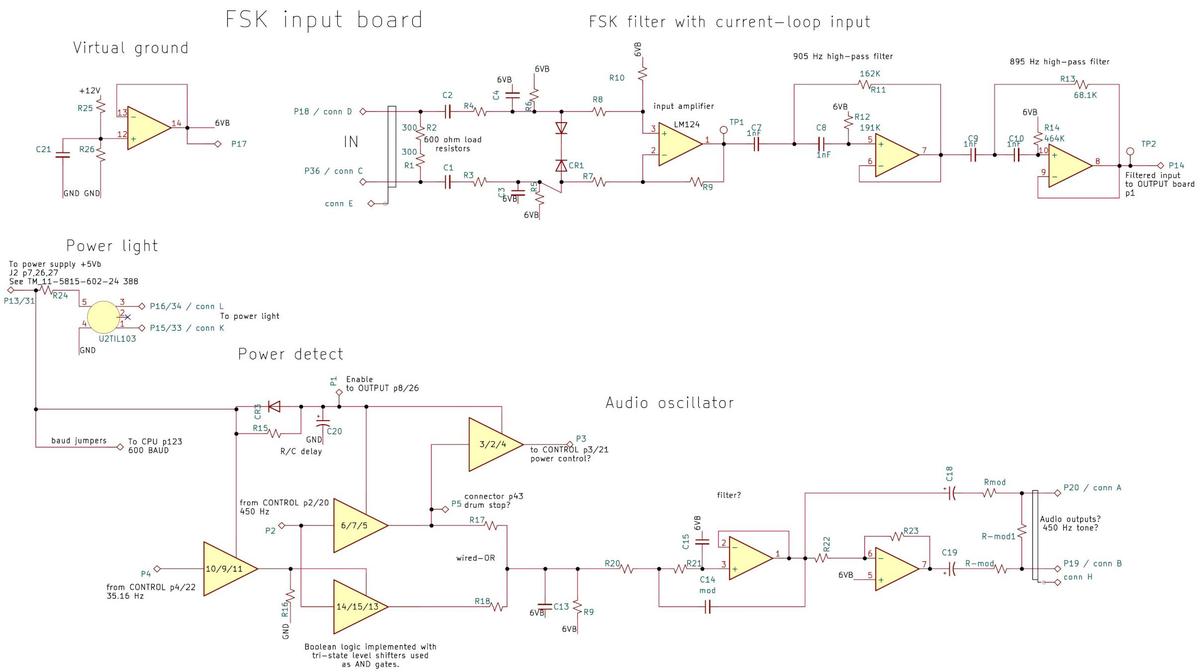

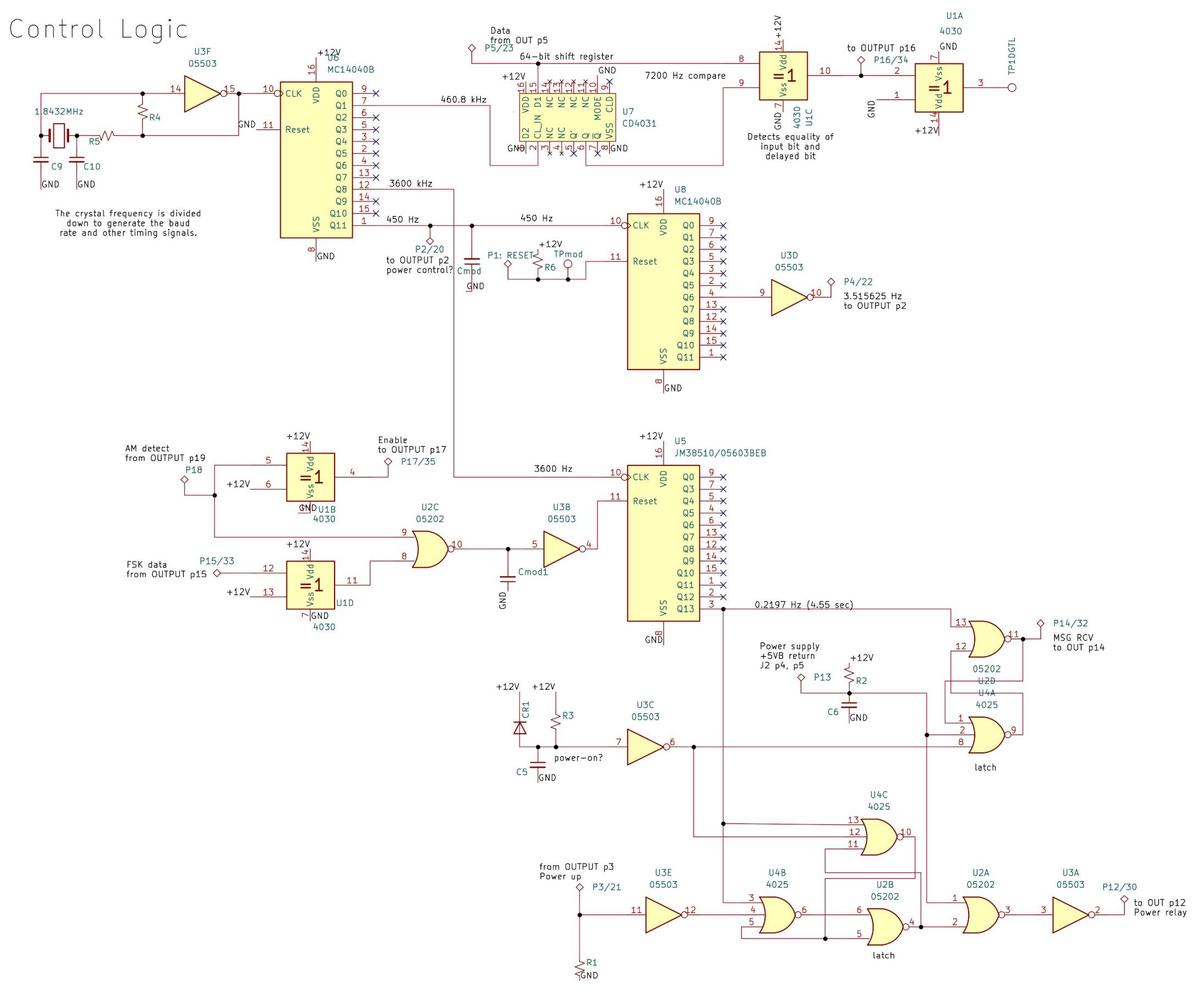

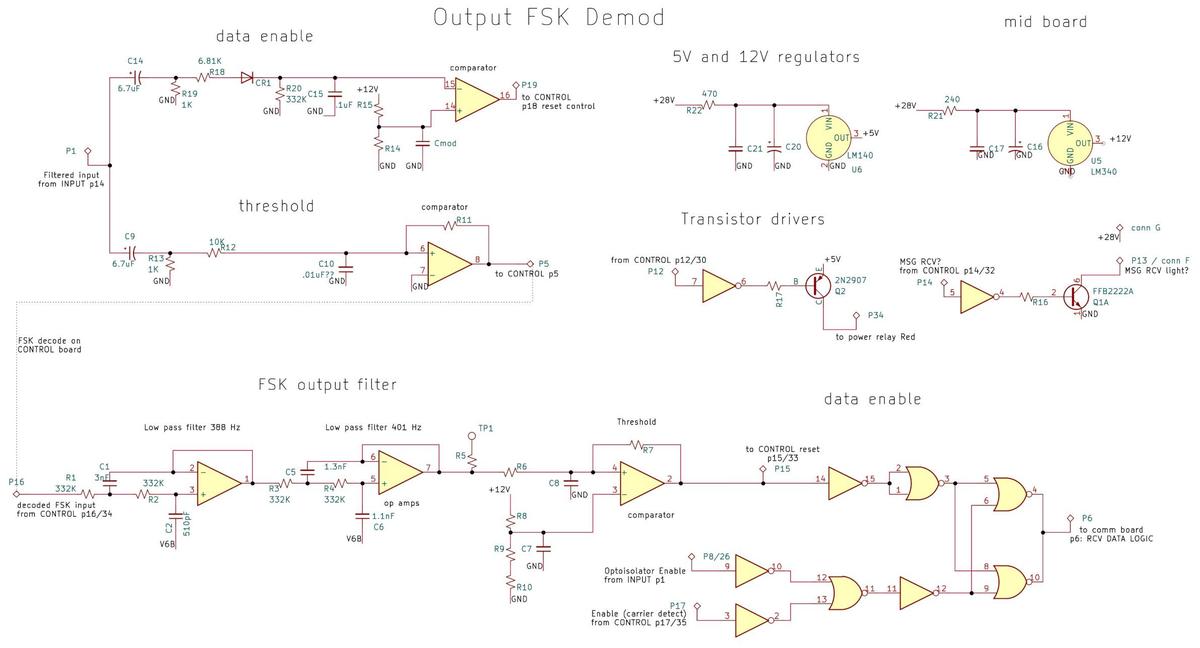

The original military teleprinter received data as a serial bitstream. However, on the Space Shuttle, data was encoded as frequencies on the audio link. Three custom boards were constructed to demodulate the audio data so the rest of the printer could handle it. These boards also performed Shuttle-specific tasks such as powering up the printer when a message comes in, and then returning the printer to standby mode. I reverse-engineered these boards to determine how they work and to determine the data encoding. (Schematics are in the footnotes.7) In this section, I'll discuss these three boards, which are on the left side of the printer.

To summarize, the serial bitstream is encoded with Frequency Shift Keying, with a 1 represented by 3600 Hz and a 0 represented by 7200 Hz.6 The serial data is transmitted at 600 baud, even parity, one stop bit. The demodulation process first converts the input audio to a digital signal by thresholding it. (That is, the input sine wave is converted to a square wave.) The digital signal is autocorrelated to distinguish the 3600 Hz and 7200 Hz signals, recovering the underlying serial data. This signal is passed to the printer's logic boards (part of the original military teleprinter), which convert the serial signal to ASCII bytes and prints them.

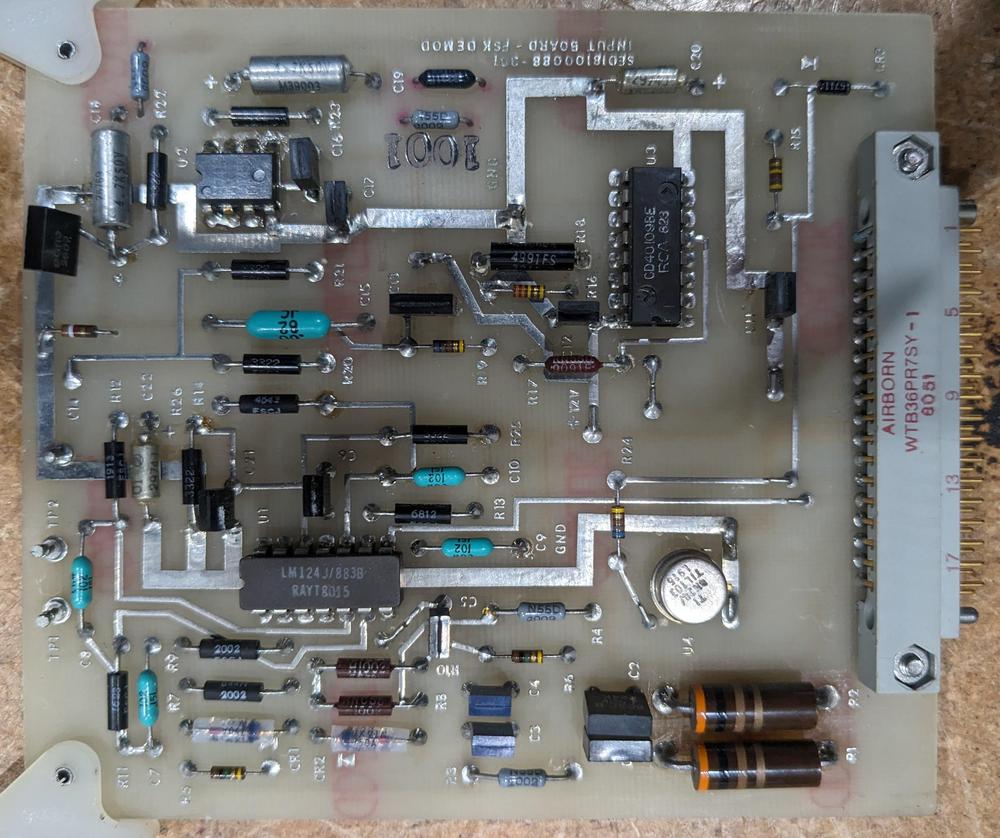

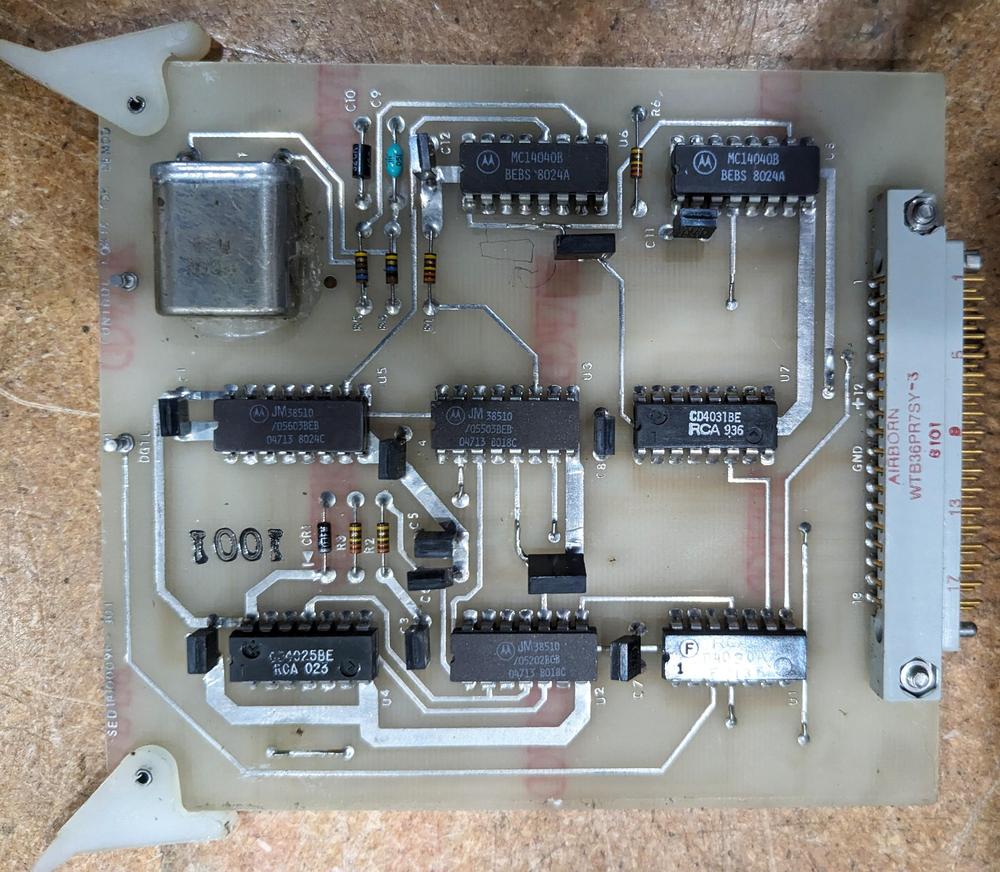

Signal processing starts with the "FSK input" board, shown below. First, it amplifies the input audio signal. (The two large resistors provide a 600 Ω load for the audio input.) Next, a 900 Hz high-pass filter eliminates low-frequency noise. (The filter is implemented by a two-stage Sallen-Key topology.)

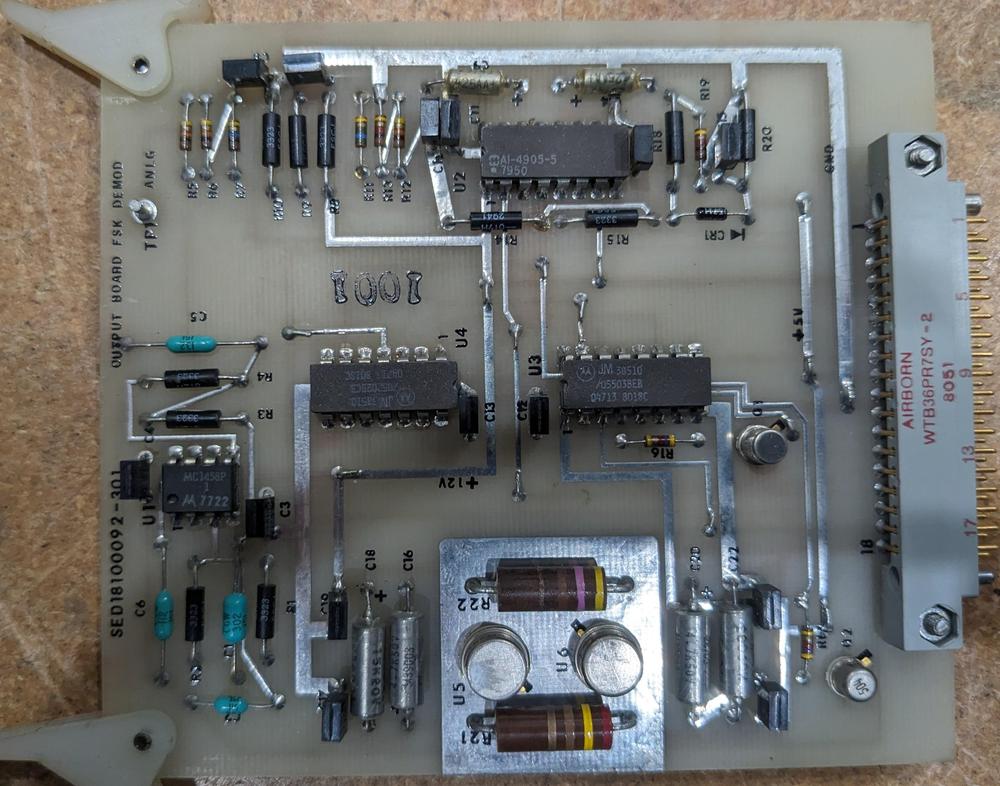

The signal bounces from board to board, going to the "output FSK demod" board next. This board has a carrier-detect circuit that turns on the rest of the printer if it detects an input signal. This allows the printer to sit idle until it receives a signal from Earth. This board also applies the threshold to the signal to turn it into a digital waveform, which goes to the "control" board.

The output board also holds the 5-volt and 12-volt linear regulators that power the three boards; these are the metal-can ICs at the bottom of the board. To reduce the load on the regulators, two large resistors drop the input voltage (28 volts) to a lower level before it is regulated.

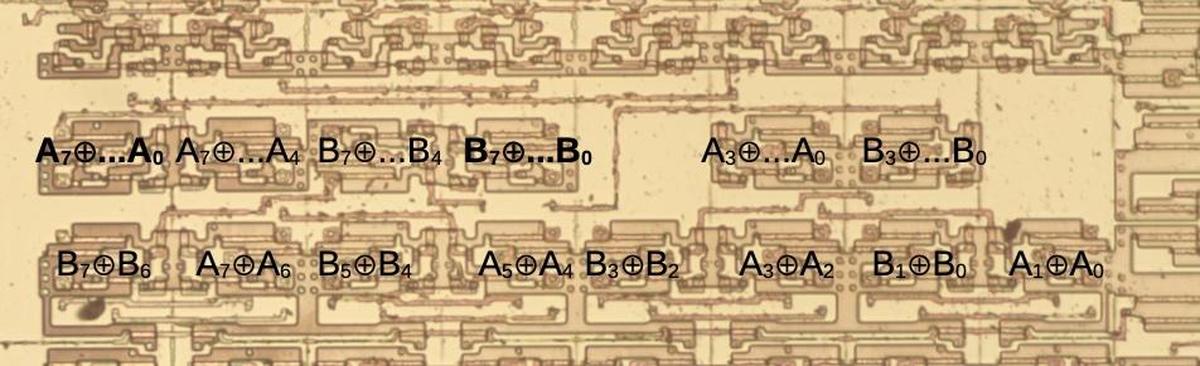

The control board holds the FSK decoder, an interesting circuit that converts the two FSK frequencies to binary by implementing a digital auto-correlator. It uses a 64-bit shift register to delay the digital input by 139 µs. The input and the delayed input are XOR'd together, generating a result that depends on the frequency. A 7200 Hz signal repeats every 139 µs, so the input and the delayed input match, yielding 0 from the XOR. However, a 3600 Hz square wave switches state every 139 µs, so the two XOR inputs will always differ, resulting in a 1 output. Thus, the circuit cleanly distinguishes between a 3600 Hz input and a 7200 Hz input.

The digital demodulator avoids some of the problems of an analog FSK demodulator. It is not sensitive to signal levels, since the signal is converted to digital. The digital demodulator is also not sensitive to harmonics, which can cause problems with analog demodulators. Finally, it doesn't require the carefully-tuned filters of an analog circuit.

The demodulated signal passes from the control board back to the output board. This board applies a 400 Hz low-pass filter and then a threshold to convert the signal back to binary. If the input frequencies are not exact, the demodulator will produce the correct 0 or 1 value over most of the waveform, but there will be glitches at the edges. The low-pass filter removes these glitches. (You might be concerned that a 600-baud signal would be wiped out by a 400 Hz low-pass filter. However, the worst case signal (alternating 0's and 1's) would be 300 Hz because it takes two bits to make one cycle, so the filter has plenty of margin.) Next, the board blocks the signal unless a carrier is detected. This ensures that random noise isn't demodulated and printed. Finally, the serial binary signal leaves the custom Shuttle boards and goes to the teleprinter's communication board, part of the standard teleprinter.

I noticed two unusual things about these boards. First, they have some modifications: "bodge" wires and added components. Second, the boards are not conformal coated, which is unusual for aerospace boards. (The four logic cards, in comparison, are protected with conformal coating.) My hypothesis is that these boards were development boards, early in the design process of the Shuttle teleprinter, so they were modified as the design changed. The teleprinter is also marked "Not for flight", which supports this theory.

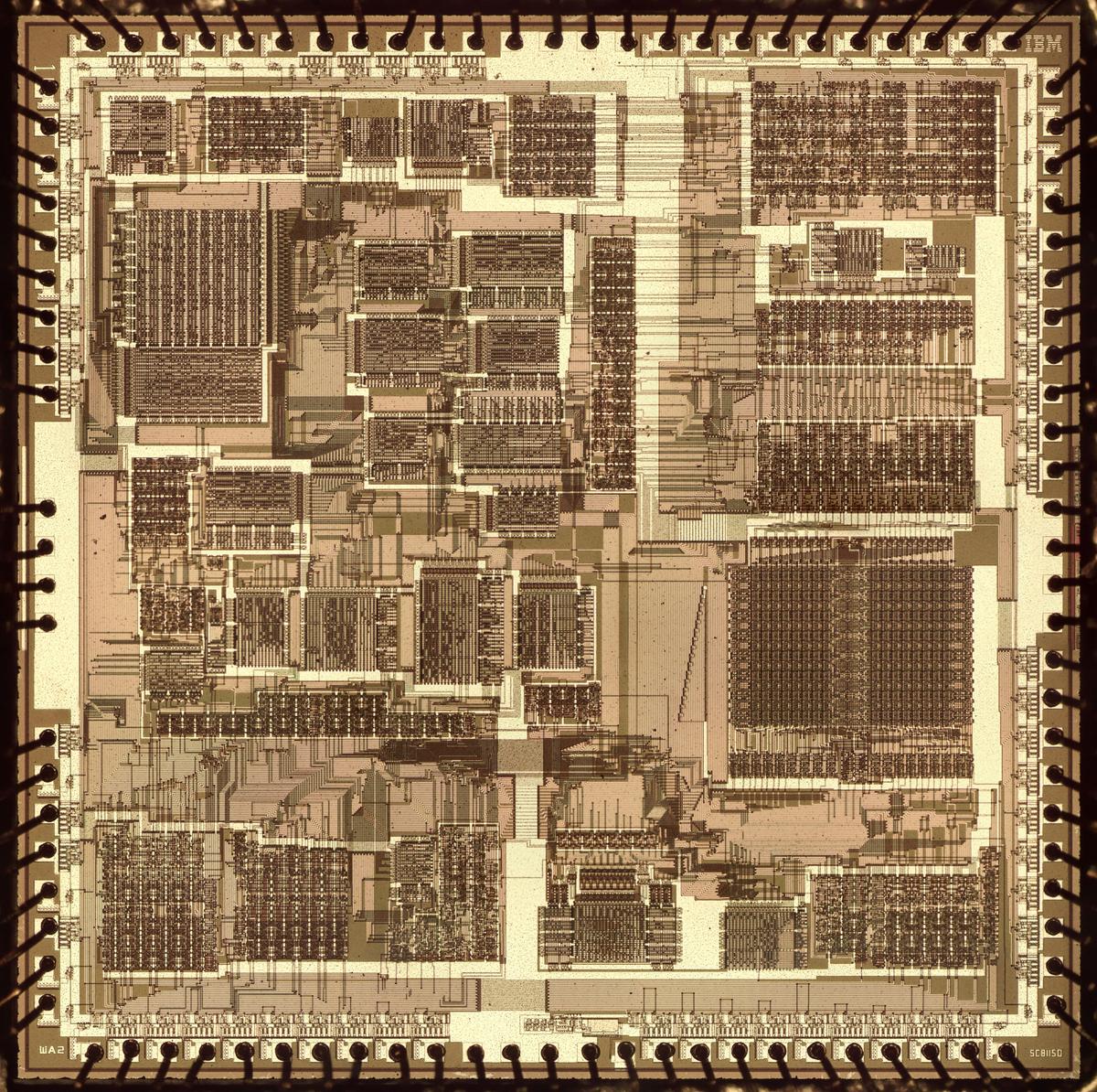

The logic cards

The military teleprinter contained four logic circuit cards: a CPU card, a memory card, a communications card, and a print control card, mounted at the right rear of the teleprinter. These cards are used unchanged in the Shuttle teleprinter.

The circuitry is more complex than you might expect, with four large cards full of ICs. There are several reasons for this. First, the cards use 1970s microprocessor technology, so it takes a lot of circuitry to do anything. In particular, many simple 7400-series logic chips perform "glue" functions: decoding addresses, buffering data, latching signals, and so forth. Moreover, a drum printer is inherently complicated, since 80 hammers must be driven at the right time based on the desired characters. Third, the teleprinter is very flexible, supporting multiple signal levels and two character formats (ASCII and Baudot). Most surprisingly, the teleprinter implements a word processor, allowing messages to be composed and edited offline. Of course, since the Shuttle's teleprinter is only used to receive data, and doesn't even have a keyboard, the word processor feature is entirely useless.

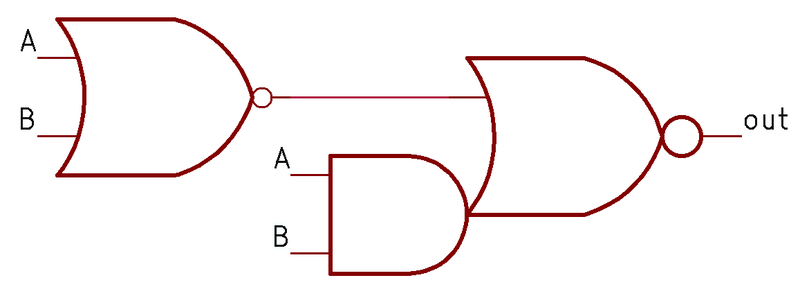

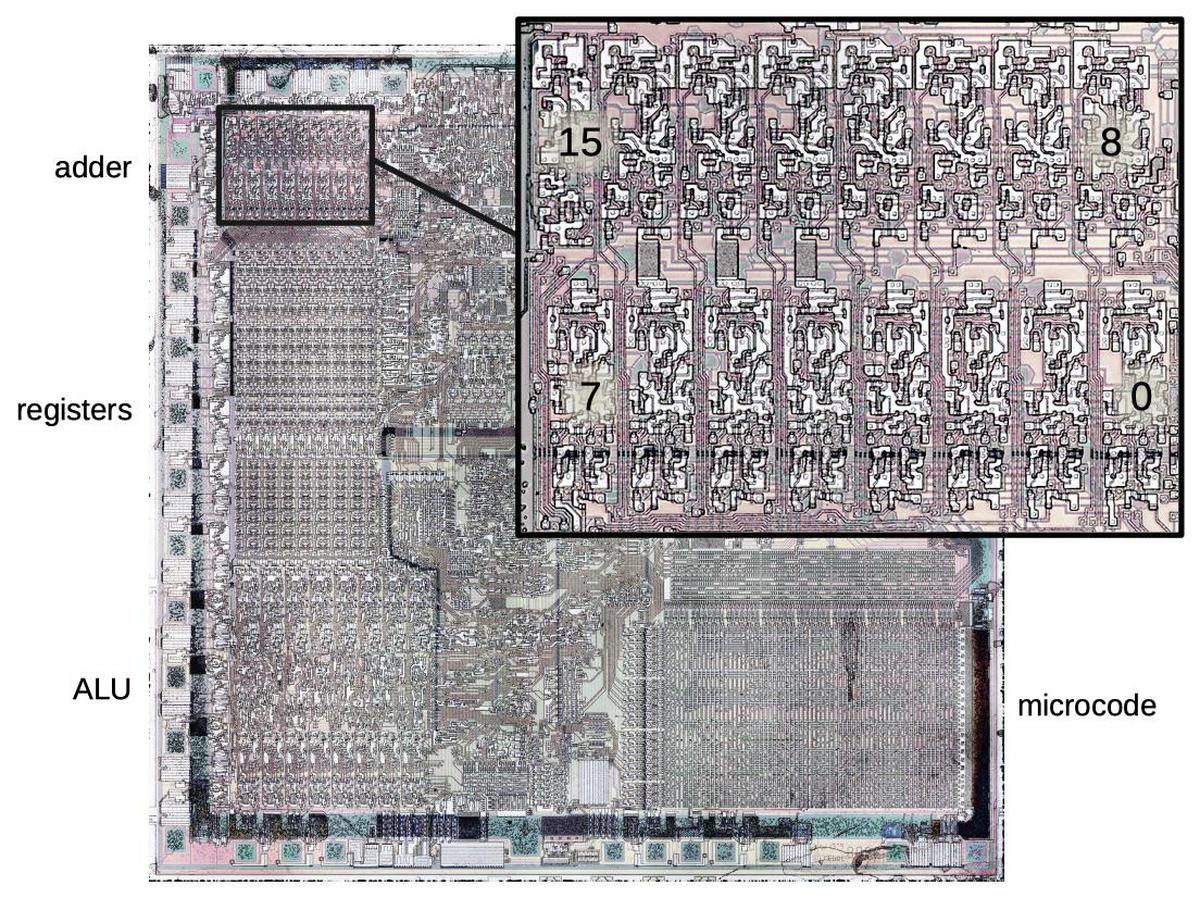

The CPU card

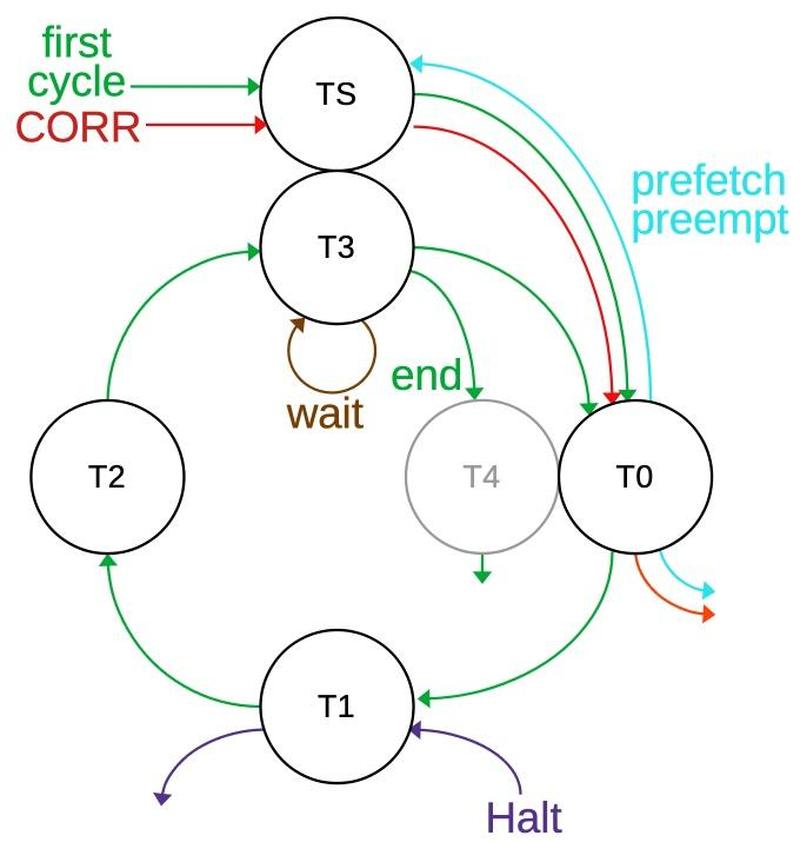

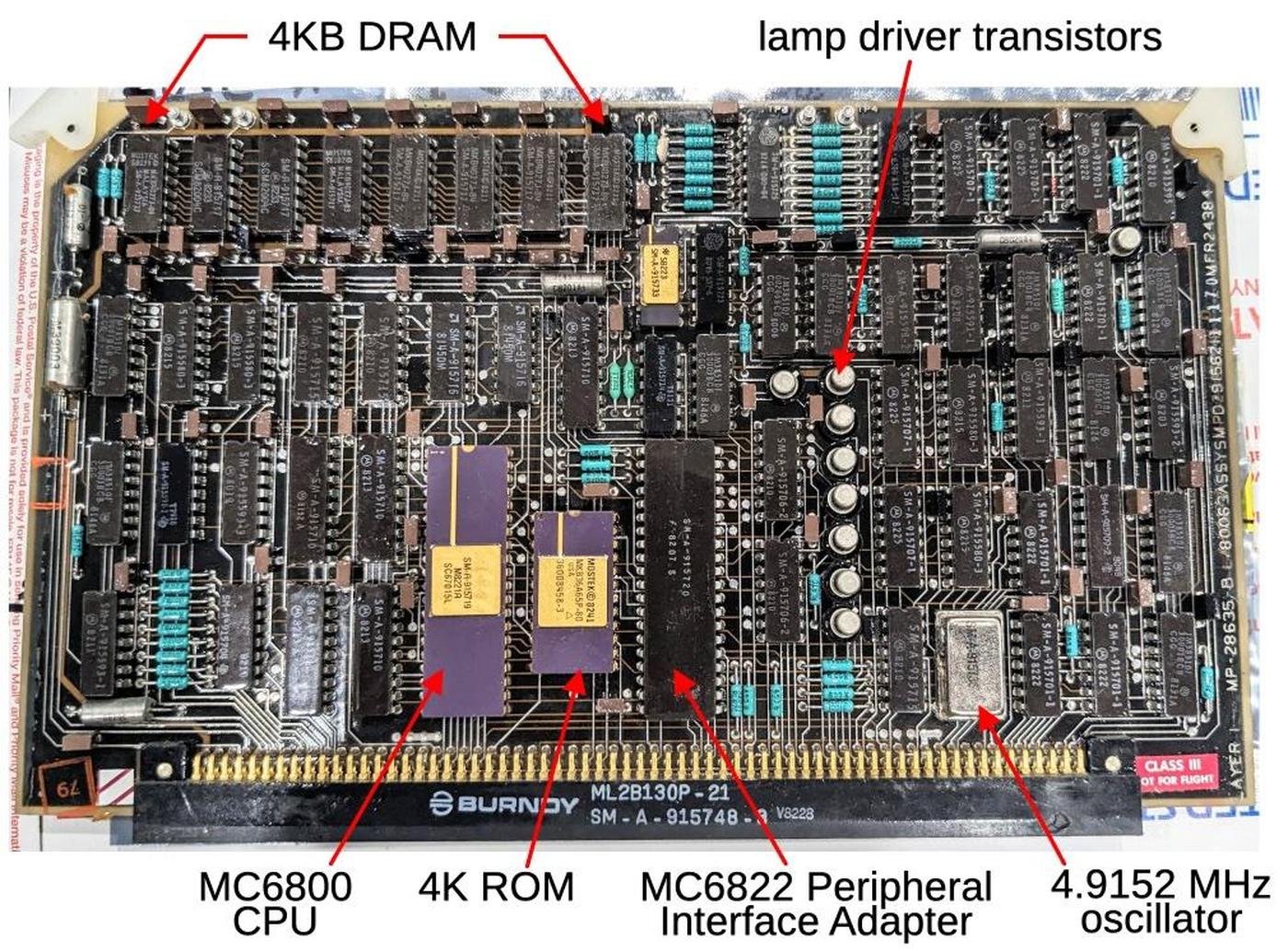

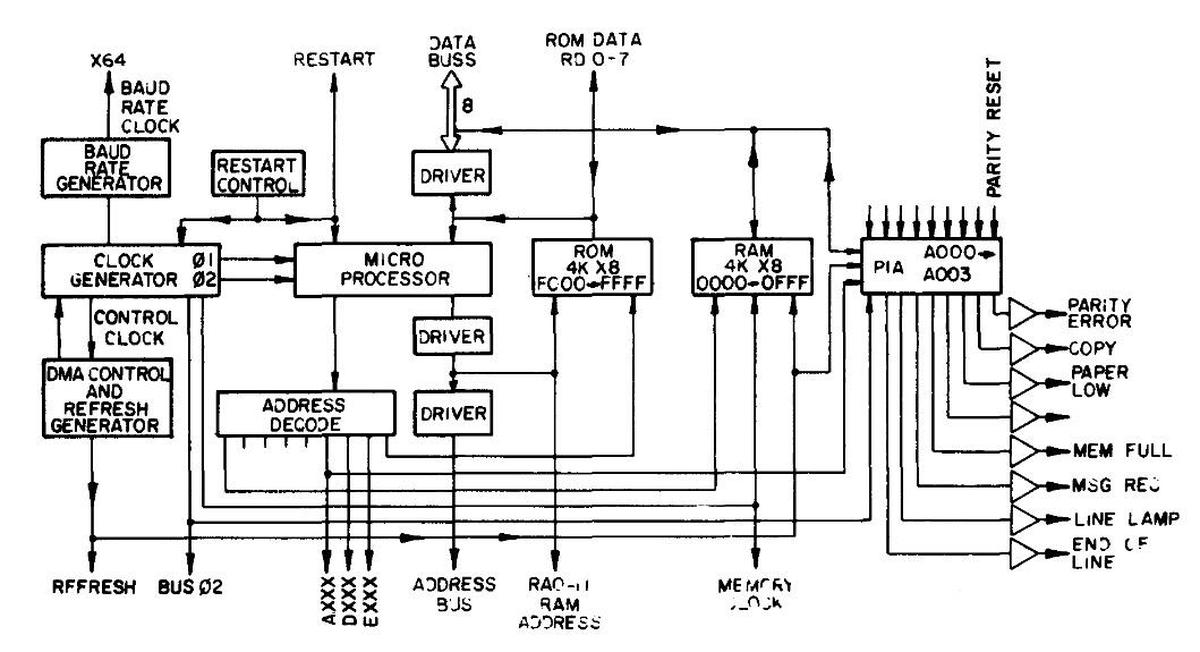

The CPU card holds the microprocessor that controls the teleprinter. Its most important function is to convert a line of ASCII characters into print drum codes. These codes are stored in memory for use by the print control card. The CPU also implements configuration and self-test functions.

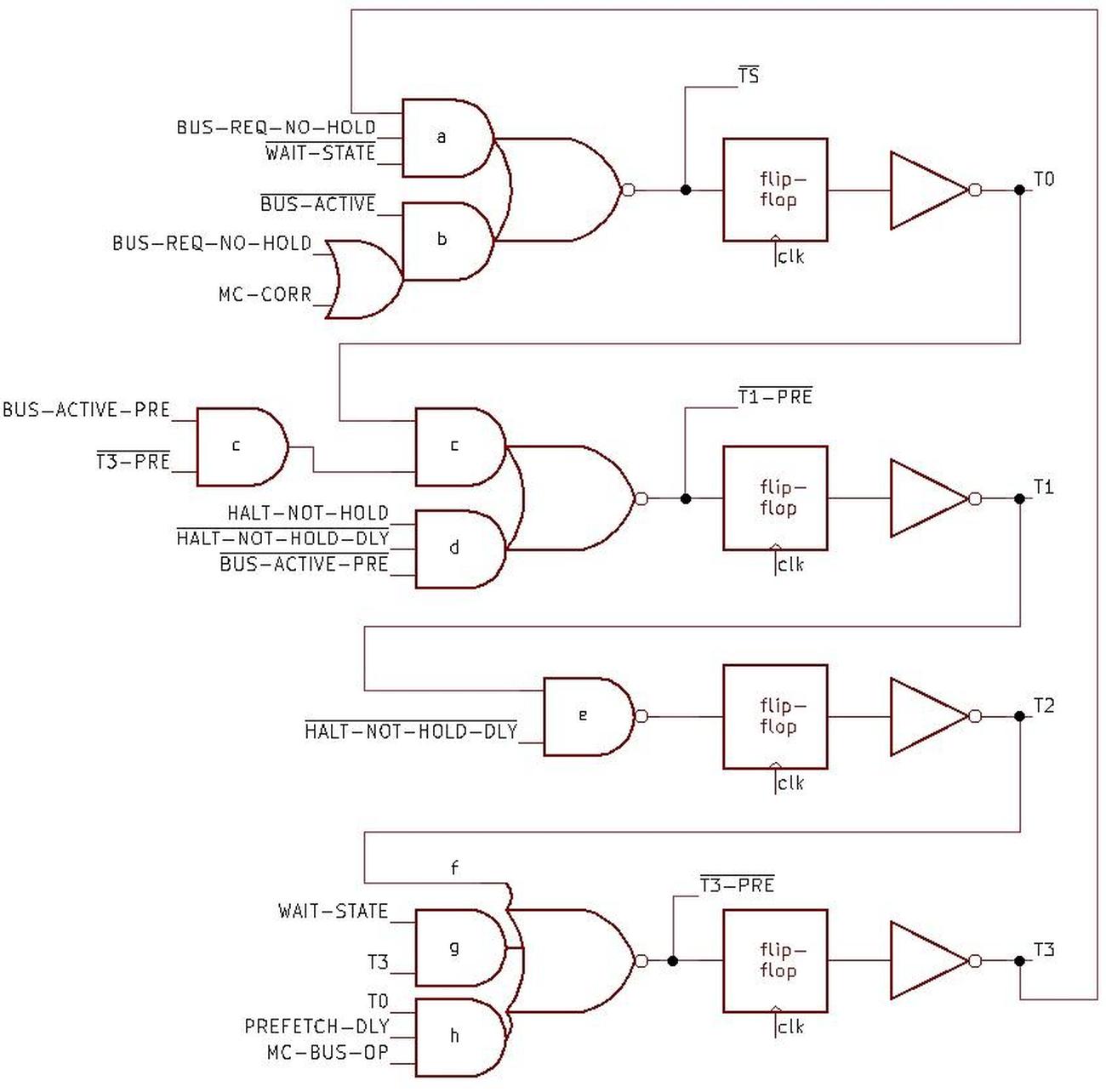

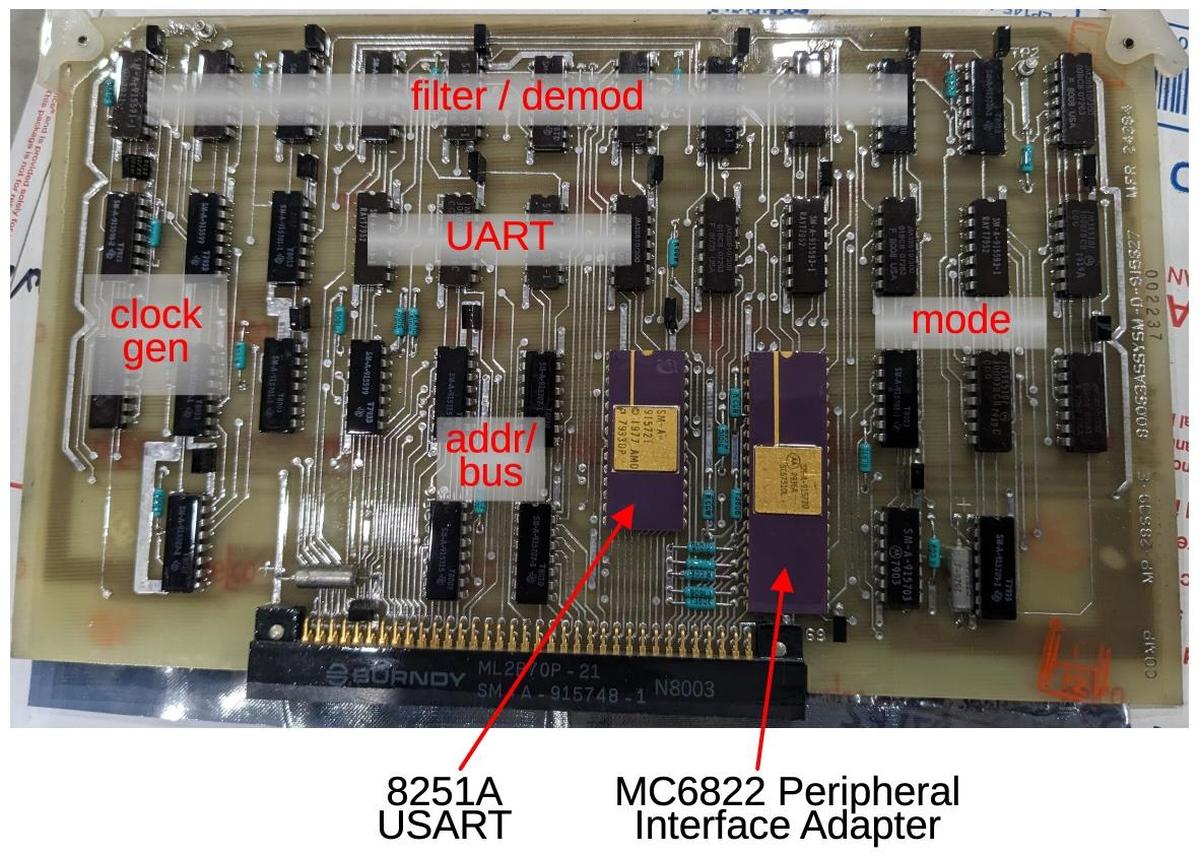

The diagram below shows some of the main components. The CPU card contains a Motorola 6800 CPU, 4 kilobytes of memory, and a ROM that holds its program code.8 Inconveniently, all the IC part numbers are military numbers so it takes some investigation to determine what a part really is. The MC6822 is a Peripheral Interface Adapter, a Motorola chip that provides two parallel I/O ports. This chip is used on three of the cards to support a variety of I/O tasks. On the CPU card, the I/O ports drive eight status lamps (most of which were removed for the Shuttle teleprinter) as well as internal status signals such as "paper low" or "keyboard present" and the baud rate setting input.

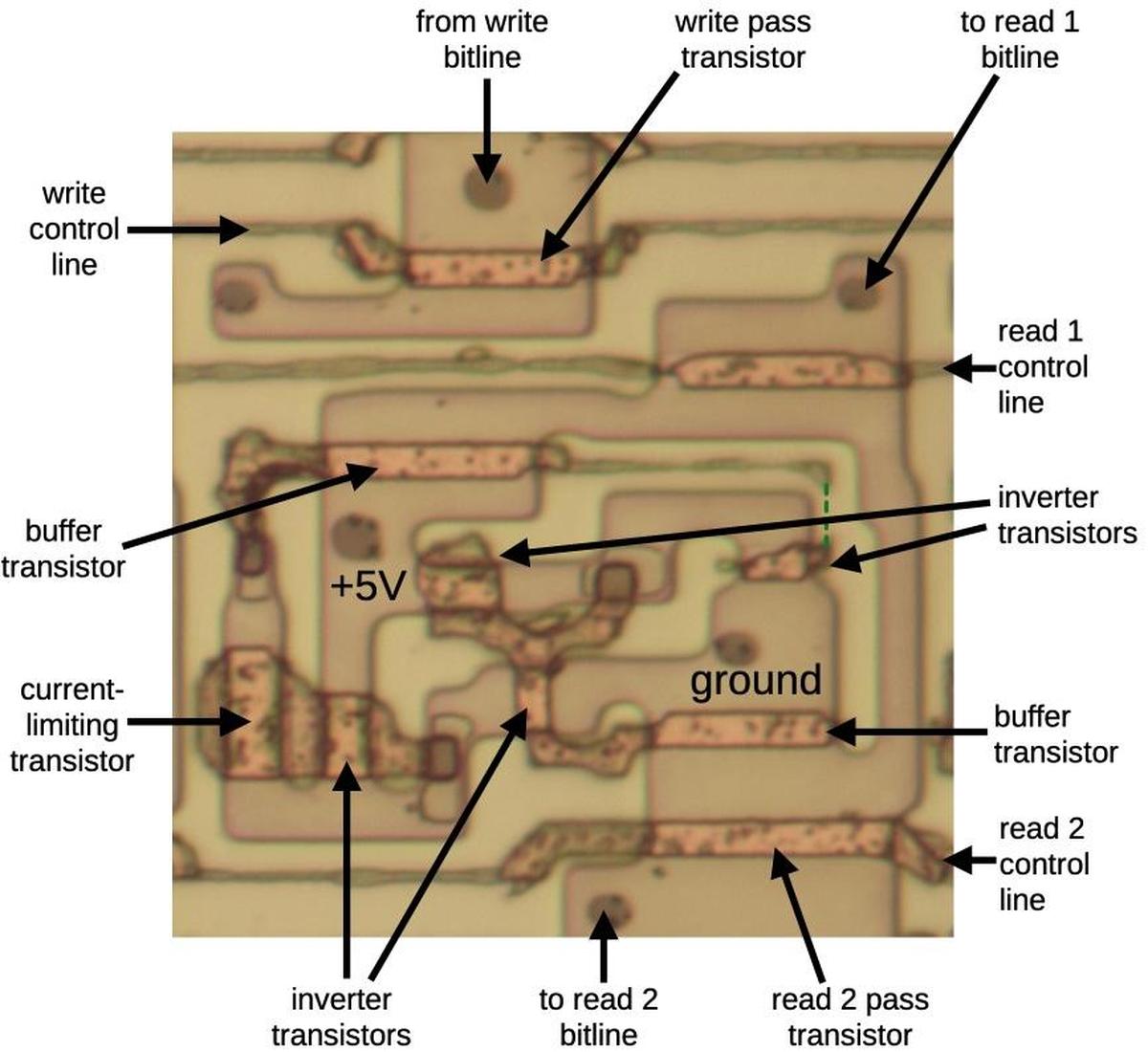

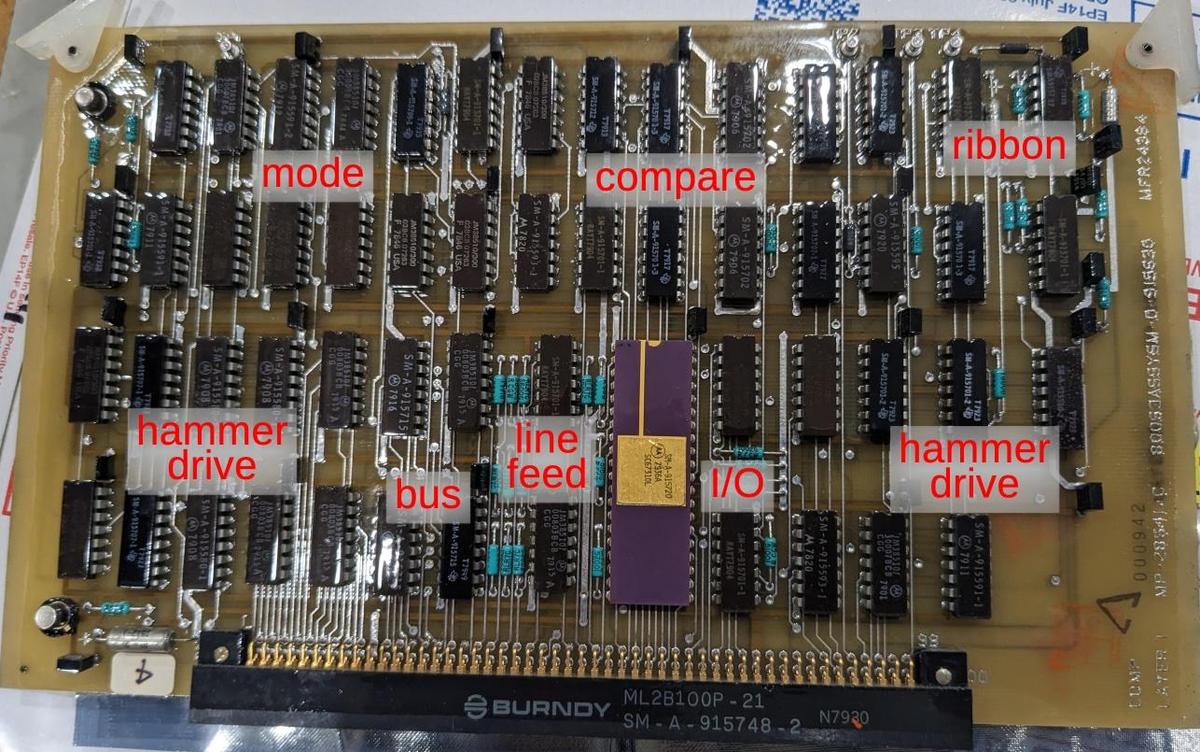

The print control card

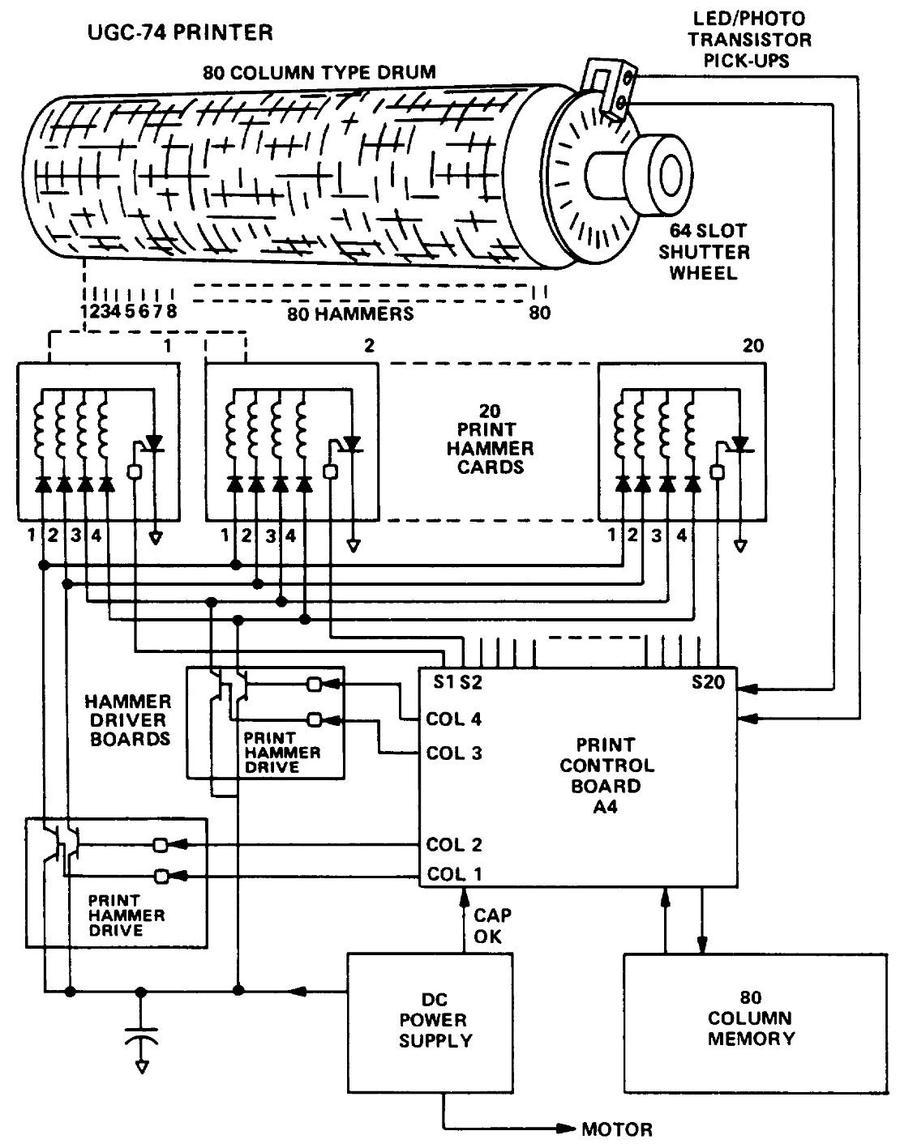

In a sense, the print control card is the heart of the printer, since it causes characters to be printed by firing hammers against the rotating drum. As the drum goes through one revolution, all 64 characters will spin past each of the 80 print positions. By firing hammers at the exact time, the card prints a line of text.9 In more detail, for each row on the drum, the printer card scans through the 80-character memory buffer using Direct Memory Access (DMA). If the value in memory matches the current drum row number, the hammer is fired. Note that the hammers don't fire simultaneously, but in sequence as memory is scanned.

The diagram above shows the interaction between the drum, the print control card, and the 80 hammers. The hammers are implemented on 20 print hammer cards, each with 4 hammers. Electrically, the hammers are arranged in a matrix. One wire out of 20 (S1-S20) selects the hammer board, the group of four. Another wire selects one of four hammers (Col 1-4). This approach simplifies the electronics, since 20 + 4 driver circuits and wires are used, rather than 80 (one for each column). The print control card is synchronized to the drum by two photo-transistor sensors that detect the drum's position. One sensor is triggered on each row, while the other sensor triggers once per revolution.

The print control card is shown below, with the main functional blocks labeled. The large purple-and-gold chip is the PIA, the same I/O chip that appeared on the CPU card. It handles a variety of signals such as the self-test request, paper out, and the drum stop signal. The mode control logic generates timing signals depending on the printer's mode. The data compare logic increments the row counter on each drum pulse, and compares the row counter to the value read from memory.10 The hammer driver circuitry on the left selects one of the 20 hammer cards, while the hammer driver circuitry on the right selects one of four hammers. The ribbon circuitry raises and lowers the ribbon so the ribbon doesn't block the text when the printer is idle. The line feed circuitry advances the paper for a line feed operation.

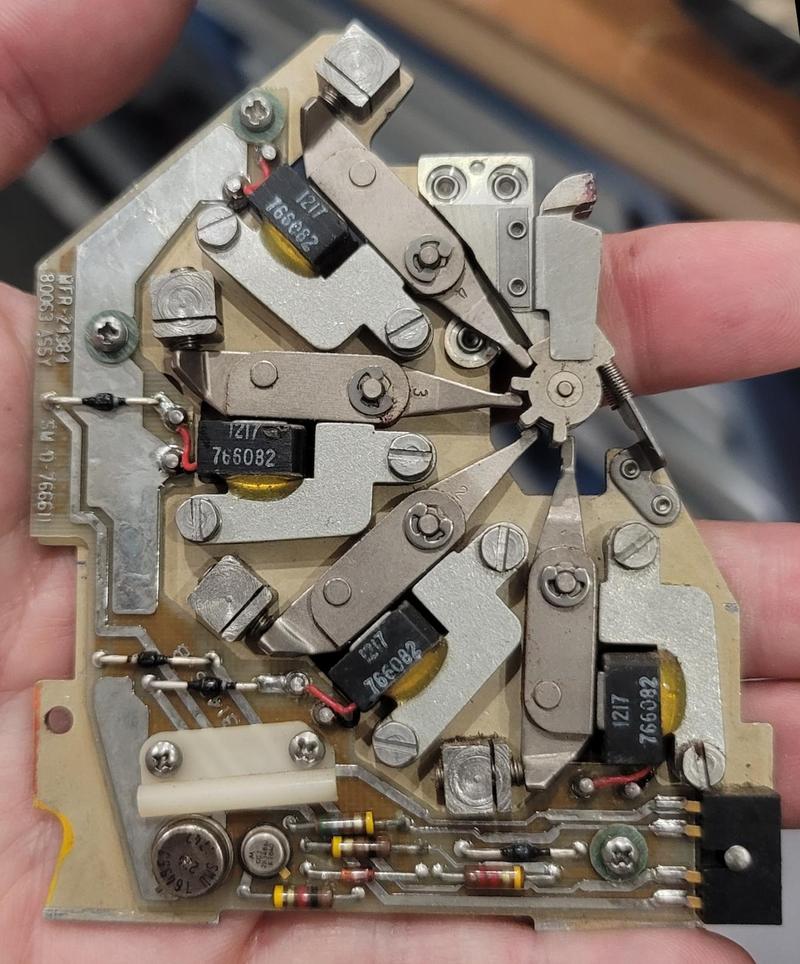

The photo below shows one of the hammer cards, with four hammers. Each hammer has an electromagnet that pulls a lever, rotating the hammer wheel, and causing the hammer to strike the paper. (The hammers themselves are in the upper right of the photo.) A screw adjustment controls the distance between each hammer and the paper, allowing precise adjustment of the timing. (Marc had to carefully adjust all the hammers to make the print quality readable.)

The communication card

The communication card handles the teleprinter's serial data input. The key chip is the 8251A, a USART (Universal Synchronous/Asynchronous Receiver/Transmitter). This complex chip performs the conversion between the serial data stream and the bytes that the processor uses. (Note that the military teleprinter both sent and received serial data, while the Shuttle teleprinter only receives data.) The chip has a few support chips, labeled "UART" in the diagram below. The board has another Peripheral Interface Adapter chip, providing two I/O ports. These ports have functions such as reading the serial line settings (ASCII vs. Baudot, odd or even parity, number of stop bits, and current loop levels).

The board also has circuitry to generate the clock pulses for the selected baud rate. The mode circuitry handles various phases of transmit/receive. The filter/demod circuitry handles different input types, digitally filtering and demodulating as necessary.11

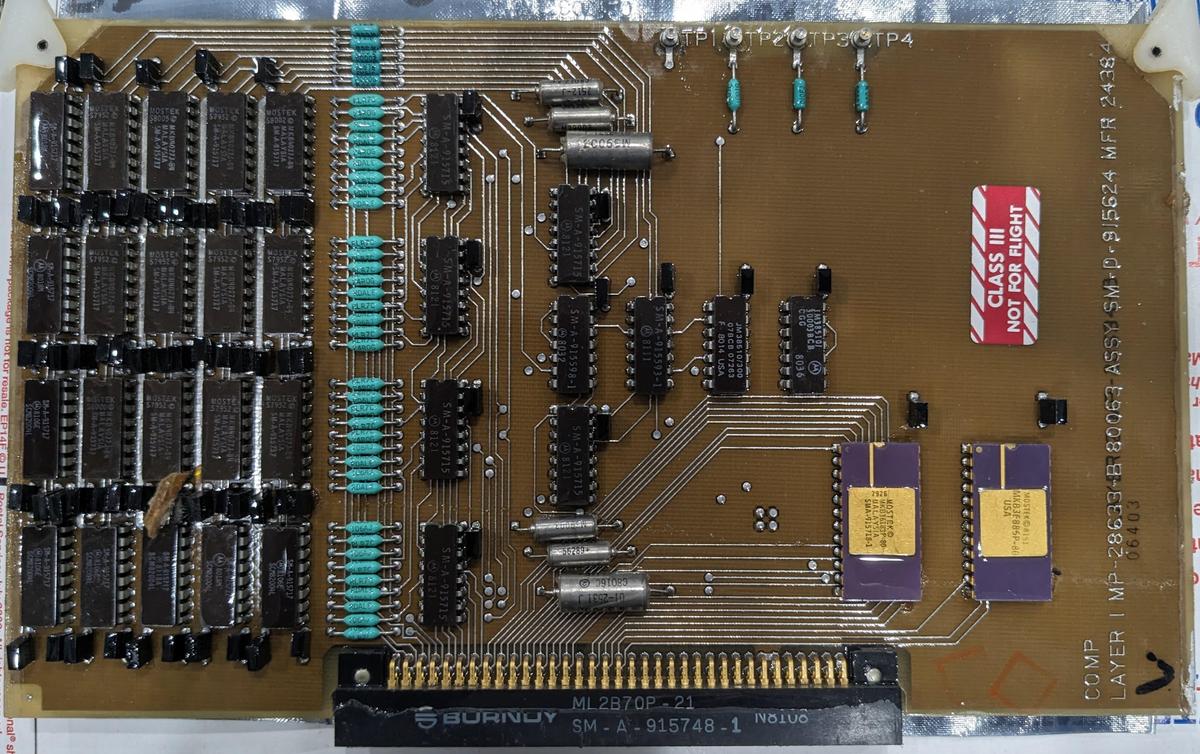

The memory card

The memory card supports the word-processing feature. It provides additional RAM to hold the text buffer as well as the ROM holding the software for editing. The 16 DRAM chips on the left (MK4027) provide 8 KB of RAM while the two ROM chips on the right provide 8K of ROM. The chips in the middle to the right of the resistors split the 12 address bits into row and column addresses as required by the RAM chips. The address signals go through the numerous 24 Ω resistors in the middle; I don't know why. According to the manual, the printer operates fine without this card, except without the word processor. Since the word processor was irrelevant to the Shuttle, I wonder why this card wasn't removed to reduce weight.

The power supply

The power supply board (shown earlier) implements separate power supplies for different parts of the printer.12 The supplies are implemented as switching power supplies, which were not as common at the time as now. The microprocessor supply provides +5V, +12V, and -5V, voltages required by memory chips in the 1970s. A separate switching power supply provides +5V, -8.6V, and +8.6V for the keyboard, dustcover, and interface module, components that were removed for the Shuttle teleprinter. Another supply powers the printer's status lamps.

The drum motor supply is important because its voltage is regulated to control the rotational speed of the drum. A sensor on the drum provides a feedback pulse for each row on the drum. (I think the drum speed is 868 RPM.) These pulses control the drum motor's switching supply. If the drum spins too slowly, the voltage is increased, and similarly if it spins too fast.

The hammers have an unusual constant-current power supply. When the printer is active, this power supply generates +18 V. However, the power supply is designed to use a constant current of 600 mA regardless of the hammer activity. A capacitor provides a reservoir of power that is filled by the constant current. If the hammers are using less current, the excess current is bled off through a resistor. The purpose of this is "to mask printing intelligence during periods of message traffic." In other words, if you used a teleprinter in the embassy in Moscow, for instance, spies could monitor power transients to see when hammers are firing, and perhaps figure out what is being printed. By keeping the current constant, this source of intelligence is blocked. Of course, this feature is useless on the Space Shuttle and only wastes power.

The military teleprinter accepted multiple input voltages: 22-30 VDC, 115 VAC, or 230 VAC, along with a 12 VDC battery backup. The transformers and diodes to support these voltages were part of the interface module that was removed for the Shuttle teleprinter. Instead, the Shuttle teleprinter is powered by 28 VDC.

Mechanical changes

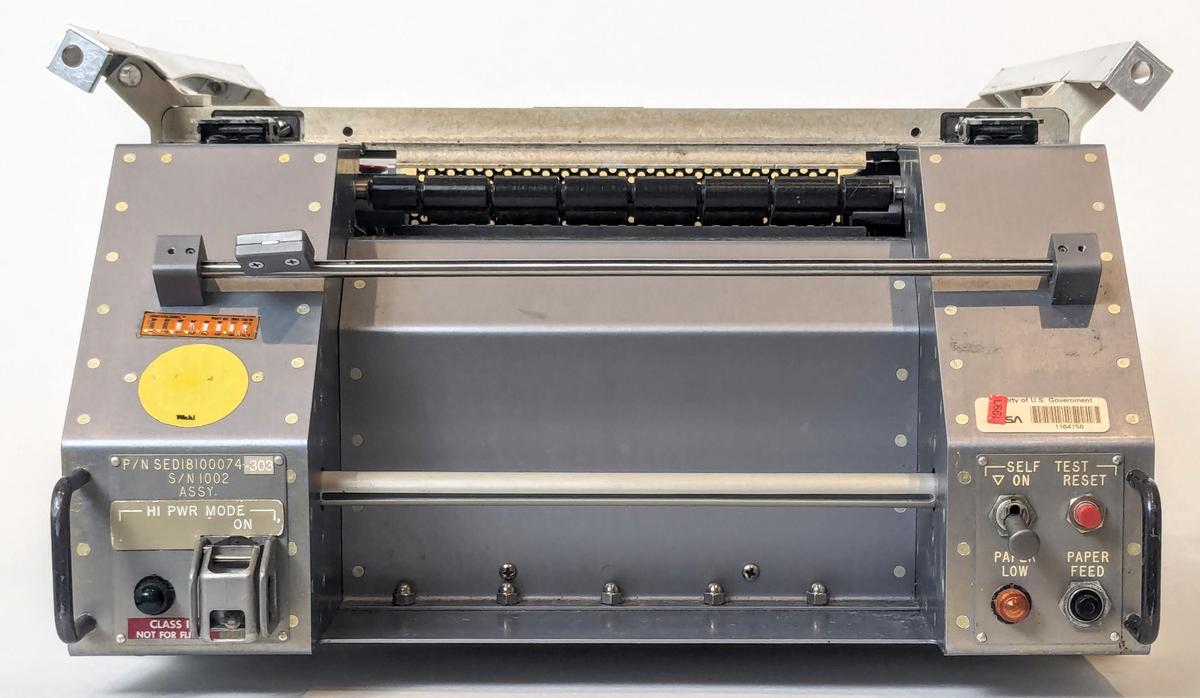

The military teleprinter underwent significant mechanical changes to make it suitable for the Shuttle. These changes reduced its weight from 100 pounds to 59 pounds. The most visible change to the printer is the removal of the keyboard. The entire front section of the printer was replaced, removing the controls that were not needed in the Shuttle.13 The rugged frame of the original printer was replaced with a lighter-weight (but still substantial) frame. Horizontal rails were added to the frame to support the printer in the Shuttle locker.

The photo below shows the front of the Shuttle teleprinter. While the military teleprinter had numerous lights and switches on the front, the Shuttle teleprinter has just two lights and four switches.

NASA was concerned that the temperature of the teleprinter could become hazardous to the astronauts. To mitigate this danger, the teleprinter had a large heat-sensitive warning sticker. The yellow sticker on the left of the teleprinter changes color and displays an image if it heats up: it shows a bandaged hand and the word "HOT". Above it is an "Omegalabel" temperature monitoring sticker that shows the highest temperature the device reached. There are more of these stickers inside the teleprinter on various motors.

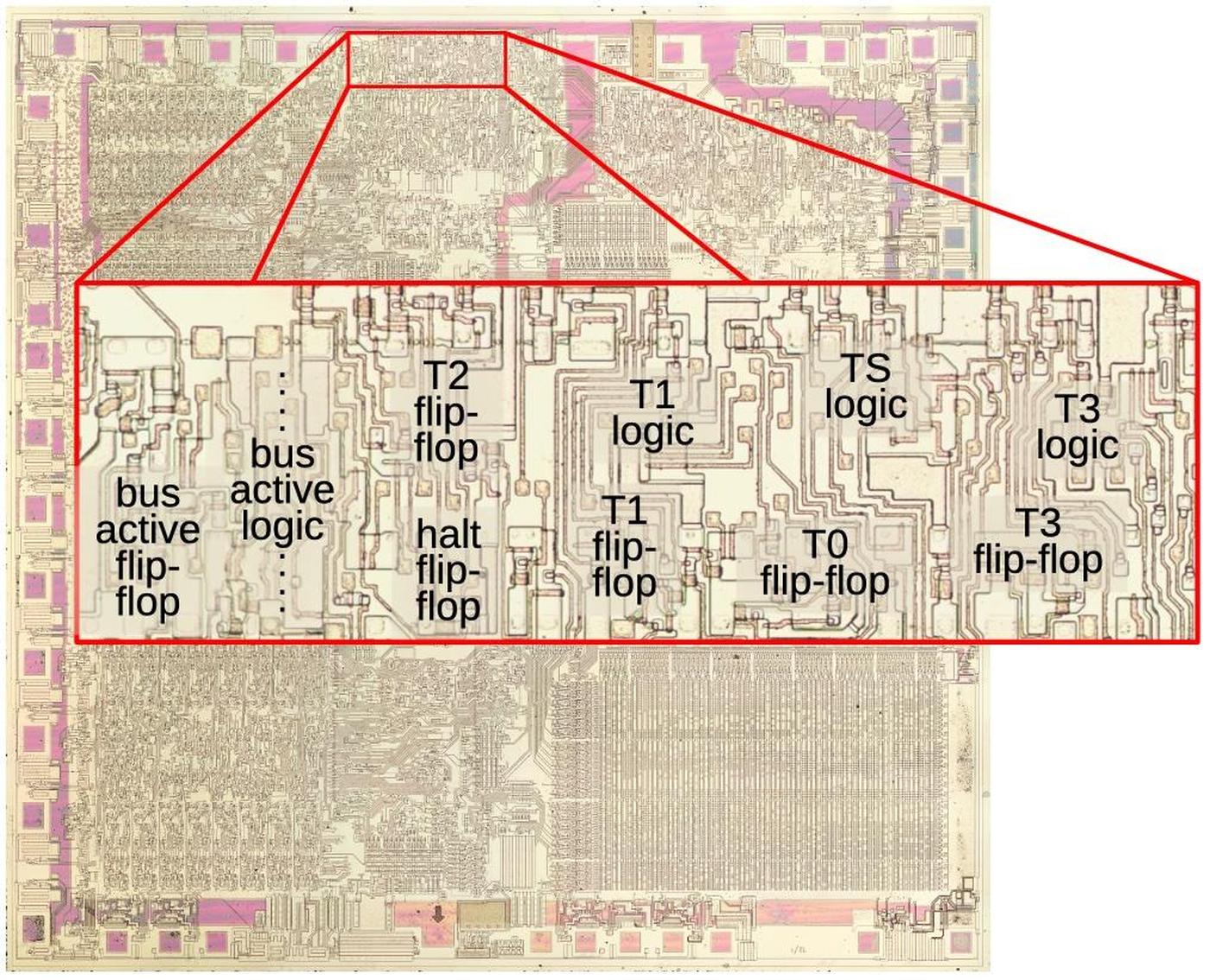

The Interim Teleprinter inside the Space Shuttle

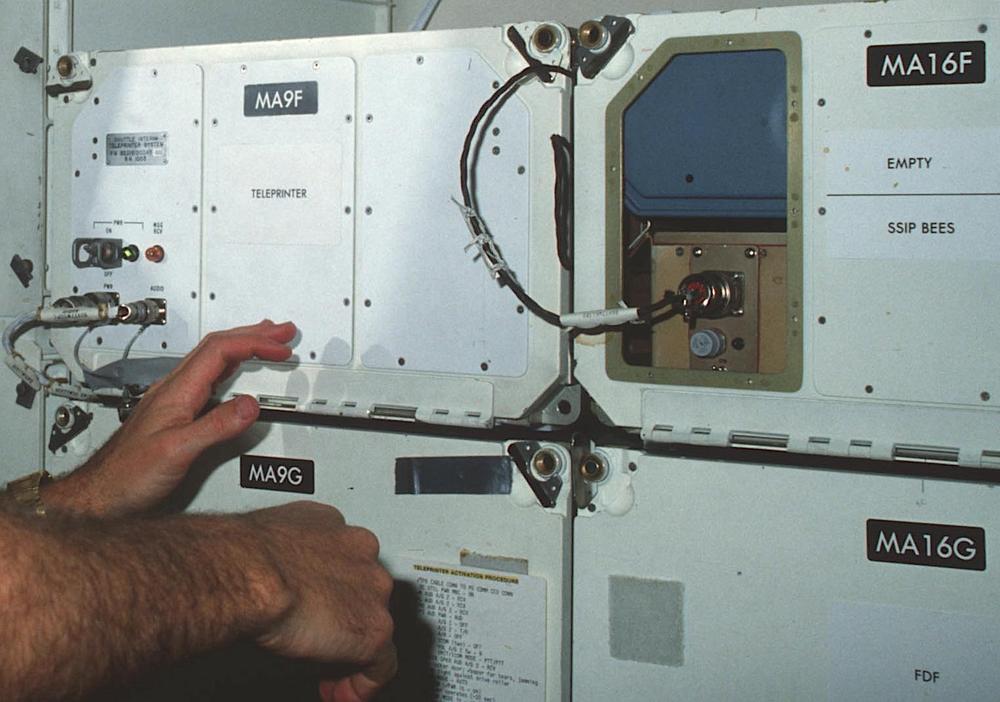

The teleprinter was too large to be mounted on the flight deck, so it was mounted in a storage locker on the middeck, one level lower. The photo below shows the location of the locker that held the teleprinter (although the teleprinter was not present in this photo), looking backward (aft) toward the airlock. The locker is denoted MA9F, indicating Mid-deck Aft, position 9F (details), in the back on the right side of the Shuttle.

The teleprinter was noisy because of its impact printing; even with it in a locker, the sound outside was 69.5 dB. The solution was to soundproof the locker with acoustic insulation. Various insulating materials were tested until one was found that passed the toxicity requirements. Another flammability waiver was required for the insulation.

Putting the teleprinter in an insulated locker without cooling caused another problem: overheating. The military teleprinter used 34 watts even while idle, which would cause the printer to become dangerously hot after just 6 orbits. The printer was redesigned to support a standby mode that used just 1 watt. When a signal from Earth was detected, the printer would power up while in use, and then return to standby mode. A circuit was added to send a tone back to Earth when the printer was activated, reassuring Mission Control that the printer had switched out of standby mode. These circuits were on the three custom Shuttle boards described earlier.

Putting the teleprinter in a locker made cabling difficult. The solution was a panel on the locker door with connectors for power and audio. The panel has a power switch and light as well as a light to indicate that a message has been received.

The photo below shows the teleprinter locker with the connection panel on the far left. Note the cables attached to the connectors. These cables went across the back of the Shuttle to the left side, where they went up to the flight deck; the cable routing was performed before launch.14 For this flight, the neighboring locker MA16F held 3300 honeybees for a student experiment.

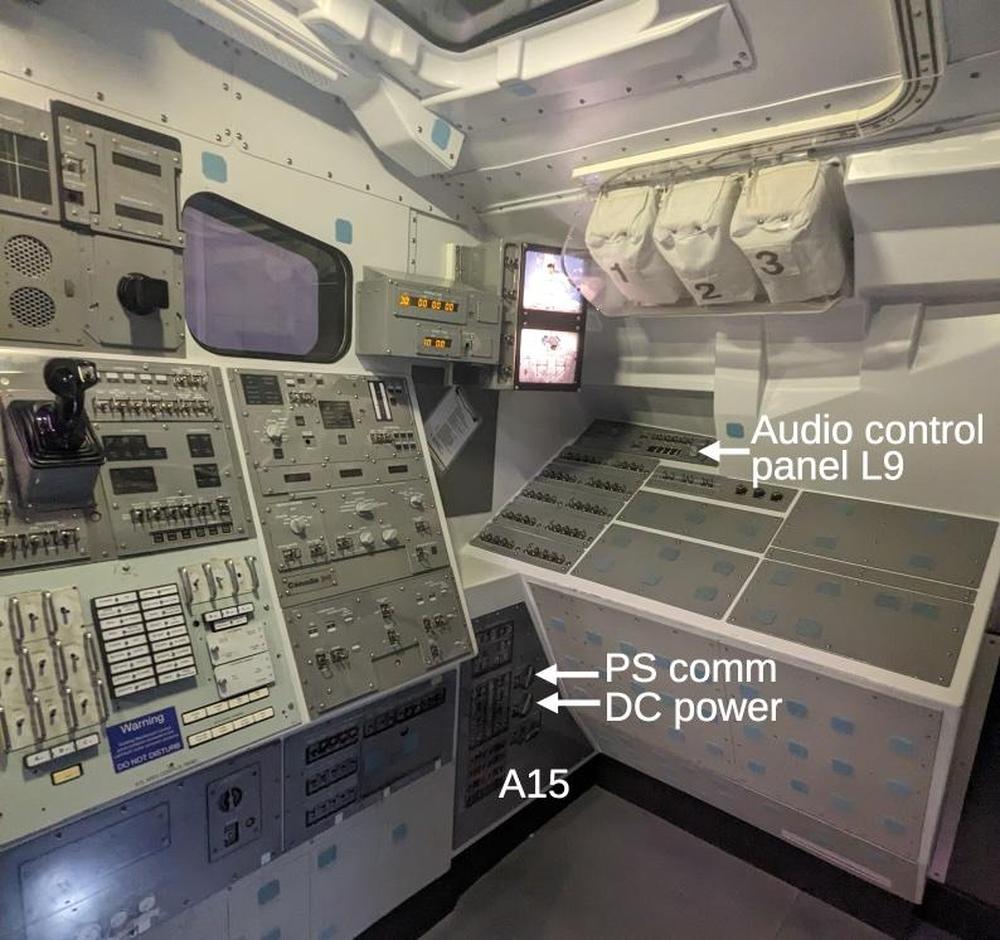

The teleprinter cables connect to the shuttle at panel A15 on the aft bulkhead of the flight deck on the left side of the Shuttle. In other words, if you sat in the Shuttle Commander's seat in the cockpit and turned around, this is what you would see.

The audio cable from the teleprinter went to the Payload Specialist communication connection on panel A15, while the power cable went to the DC power connection right below. During launch, this audio connection was needed for crew communication, so the teleprinter was plugged in after launch and the audio settings were reconfigured on panel L9. A cue card was placed above panel L9 with instructions on the teleprinter.

The teleprinter's replacements

The Shuttle teleprinter was supposed to be used for a short time until the Uplink Text and Graphics System (TAGS) entered service, but things didn't work out that way. TAGS, described earlier, was the fax-like system that could receive grayscale images, but it depended on the TDRS satellites with their support for digital data. The first TDRS satellite was launched by the sixth shuttle flight, STS-6 (1983). This allowed the use of TAGS on STS-7, but the printer promptly jammed. TAGS had constant problems with jamming; on STS-35, the printer jammed and then the unjamming tool broke. Due to the unreliability of the TAGS, the Interim Teleprinter was kept in service as a backup device. TAGS was mounted on a dual cold plate in avionics bay 3 of the crew compartment middeck (details), on the other side of the airlock from the teleprinter.

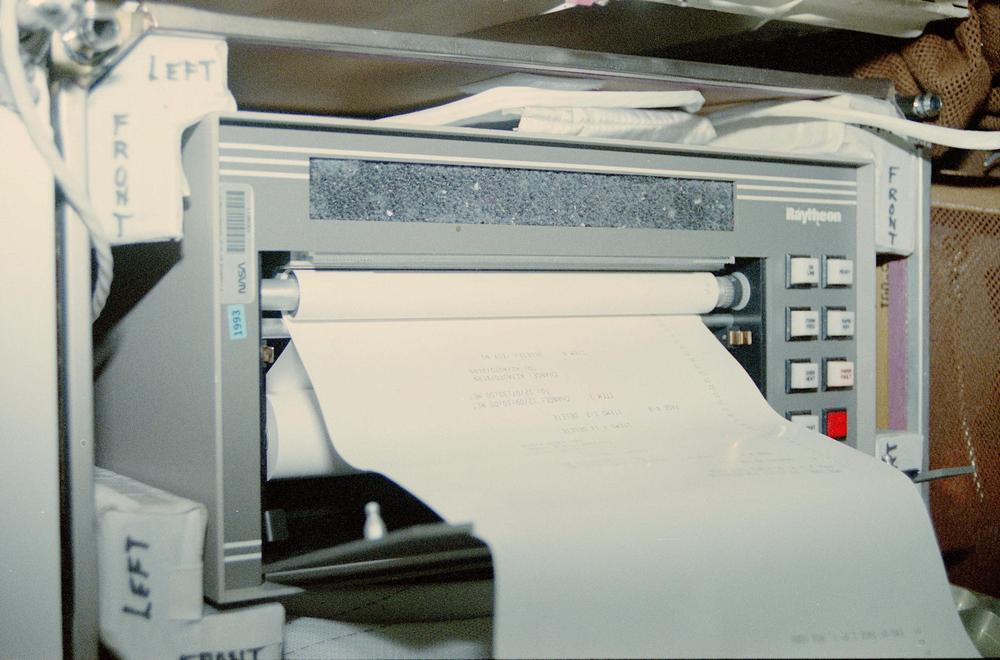

After a decade, another printer, the Thermal Impulse Printer System (TIPS) was put into service, probably on flight STS-56 in 1993. Once TIPS proved its reliability, it replaced both the teleprinter and the Text and Graphics System (TAGS). The TIPS printer was installed in mid-deck locker MF28E; the F indicates the locker was on the forward wall, not the aft wall that held the Interim Teleprinter. As a backup for the TIPS, the Shuttle flew with a second TIPS.

One motivation behind the TIPS thermal printer was NASA's desire to use more commercial-off-the-shelf (COTS) equipment instead of expensive custom equipment. The TIPS printer is the Raytheon TDU-850 printer (below), a commercial product that sold for $4950. A custom communication interface board inside the printer provided the interface between the printer and the Shuttle's S-Band and Ku-Band communications systems. This interface also allowed astronauts to use the TIPS as a printer for an onboard personal computer.

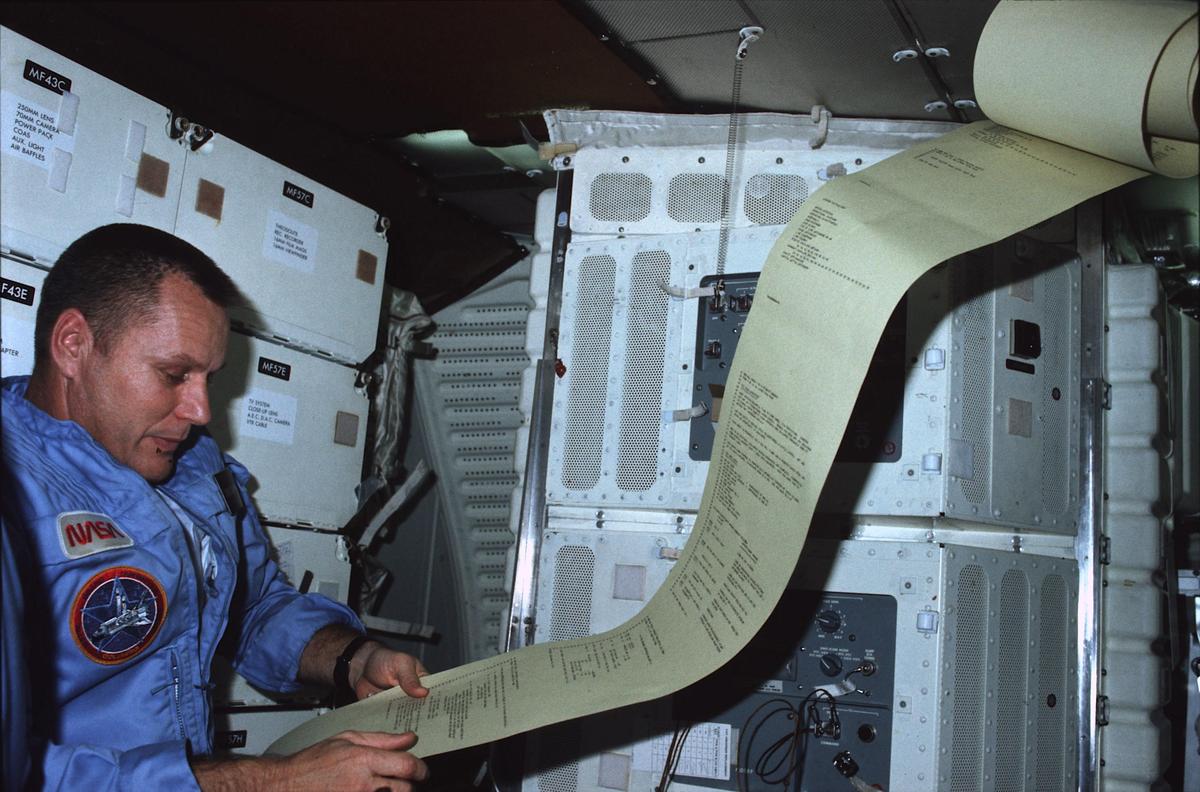

The photo below shows the TIPS printer in use, printing a long stream of output that Eileen Collins is reading. Collins was the first woman to pilot the Space Shuttle; she flew on the Shuttle four times, twice as pilot and twice as commander.

The teleprinter, operational

We succeeded in making the Shuttle teleprinter operational. The printer had many mechanical problems, mainly because the rubber rollers had turned to liquid and gummed up the mechanism. Marc disassembled the printer, carefully cleaned the mechanism, and realigned everything. I won't discuss the restoration process here since there will be a video on CuriousMarc's channel. We were able to send FSK-modulated data to the printer and it was printed successfully, as shown below.

Conclusions

At first, I thought that the Shuttle's Interim Teleprinter was a terrible design. It's absurdly heavy and was in danger of overheating. Although the design started with an existing product, much of it required redesign: the front section, the new drum, the interface, and even the frame. The design inherited features it couldn't use, such as the built-in word processor. And the constant-current feature was pointless for the Shuttle and just wasted power.

When I learned that the design had to be completed in just seven months, my opinion of the teleprinter improved. Moreover, the design had many constraints, such as toxicity and flammability restrictions, that limited the potential approaches.

In the end, the teleprinter was used on over 50 flights, acting as a reliable backup to the somewhat flaky Text and Graphics System (TAGS).16 Despite its name, the Interim Teleprinter turned out to be a long-lasting solution, not interim at all. So I have to conclude that the teleprinter was a good design, working much better and much longer than intended.17

In any case, the Interim Teleprinter is an interesting piece of hardware and I hope you enjoyed this article. Follow me on Mastodon as @[email protected] or RSS. Thanks to Marcel for providing the printer. Restoration performed with CuriousMarc, Eric Schlapefer, and Mike Stewart.

Notes and references

-

References for the teleprinter:

The Interim Teleprinter and its development is described in detail in: M.D. Schuette, “Space Shuttle Interim Teleprinter System,” in Conference record: NTC ’82, Systems for the Eighties, IEEE. (I'll call this the "teleprinter paper" for short.)

The Shuttle Crew Operations Manual has extensive information on the shuttle and some information on the teleprinter.

The teleprinter is briefly discussed here.

Some teleprinter information is in the "Crew Systems Equipment Workbook" via RR Auction.

The layouts of the Shuttle panels are in Orbiter OV-102 Display and Control Panel Configuration.

The lockers are described in Orbiter middeck/paylod standard interfaces control document.

The manuals for the AN-UGC/74 are at RadioNerds.

An enormous collection of Shuttle documents is at gandalfddi. ↩ -

The teleprinter paper mentions that Shuttle had one other option for receiving hardcopy data: the Text Uplink to Mass Memory System (TUMMS). This allowed text to be displayed on a CRT and the crew could take a Polaroid photo. This was obviously an impractical solution. I couldn't find any other references to TUMMS, so TUMMS may be a proposal that wasn't implemented. ↩

-

Specifically, the Shuttle teleprinter was based on the Honeywell Model AN/UGC-74A9(V)3 Communications Terminal. ↩

-

The mechanism of a drum printer is similar to a chain printer such as the IBM 1403 line printer: each print position has a hammer that fires when the correct character is in that position. However, chain printers have better print quality than drum printers, due to the effect of timing errors. In a drum printer, a small timing error on a hammer will cause the character to be printed too high or too low. In a chain printer, however, a timing error will cause the character to be shifted to the left or right. Vertical mispositioning is obvious and looks terrible. Horizontal mispositioning is much less noticeable since character spacing is normally slightly variable. ↩

-

To be precise, the hammer is fired 1.5 characters early due to its travel time. By the time the hammer hits the drum, the drum has rotated enough to put the desired character in place. Each hammer has a screw to adjust its distance to the drum, necessary to get the timing exact. It's amazing that this system works and doesn't produce a smudged mess. ↩

-

After reverse-engineering the boards, I found a paper on the Shuttle teleprinter that specified the FSK frequencies as 1600 Hz for a 0 and 2057 Hz for a 1, different from what we used. Perhaps the frequencies were changed during development. ↩

-

I created schematics of the three Shuttle-specific boards. Click an image for a larger (readable) version.

Schematic of the input board.Schematic of the control board.Schematic of the output board. -

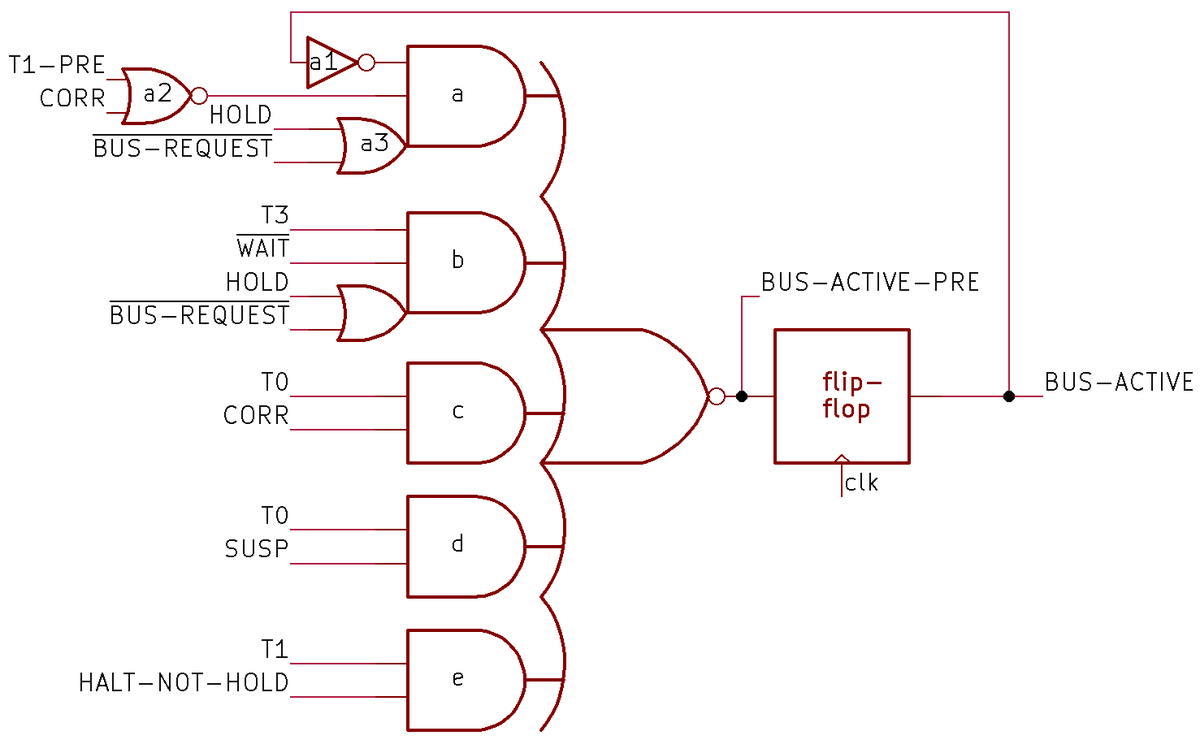

The block diagram below shows the main functional blocks of the CPU card.

CPU block diagram. From Maintenance Manual, TM 11-5815-602-24, p3-6 -

I expected that a line would be printed during one drum revolution but looking at the print pattern, it appears to take multiple revolutions per line. Perhaps the printer is avoiding hammers firing too close together to minimize current spikes. Moreover, the published print speed of 60 characters per second is considerably slower than one revolution. Or perhaps the hammer pattern is randomized so spies can't listen in and determine what is being printed. I'm still investigating. ↩

-

Looking at the circuitry, I think the memory buffer holds the drum row number for each position, and the print control card fires the hammer if the value matches the current row number. In contrast, the "obvious" approach would put the character values in the memory buffer and the print control card would match against the current drum character. The implemented solution puts less work on the print control card, which only needs to update the target comparison value once per line, rather than every character. However, it requires the CPU card to transform the input characters into row values. ↩

-

The teleprinter accepts two types of inputs: NRZ and D10. NRZ (Non-Return to Zero) is the straightforward encoding of the serial signal as 0's or 1's. The manual doesn't define D10, but I think it is Manchester encoding, using a 01 sequence for a 0 and a 10 sequence for a 1 (or inverted). The D10 signal is self-clocking, since each bit contains a transition. The demodulation circuit converts the D10 signal into a straight bit sequence. An NRZ signal can either use an external clock or an internal clock from the baud rate generator. With the internal clock, the input is sampled four times and digitally filtered since the input may not exactly line up with the internal clock. ↩

-

The power supply is explained in the Maintenance Manual. The fold-out power supply schematics in that manual were not scanned for some reason but can be found in the B&C Maintenance Manual. ↩

-

The military teleprinter contained a large interface module at the back, providing the signal and power connections to the terminal. The serial-line signals could be a 20-milliamp current loop, a 60-milliamp current loop, or MIL-STD-188/144 (similar to RS-422). The interface module converts these signals to the TTL signals used internally. The interface module also contains a power supply for the interface circuitry. Since this interfacing was not required for the Shuttle, the interface module was discarded and replaced with the Shuttle's custom FSK interface cards. The AC power supply and filtering was also removed. ↩

-

I was a bit surprised that the teleprinter cables would run for a long distance through the Shuttle. But the Shuttle is full of wires and cables running in all directions, as shown in the photo below. This photo is from the same angle as the earlier diagram showing where the teleprinter is connected. This flight was after the teleprinter was retired, but the teleprinter would have been plugged in behind the exercise equipment.

The aft flight deck of Discovery during STS-116. From National Archives. -

The teleprinter had a few problems during use. On flight STS-6, the teleprinter got stuck in high power mode. On flight STS-30, messages were illegible (link). ↩

-

The teleprinter shows the risk of building an interim solution that turns out to last much longer than expected. This also happened with the Interim Upper Stage (IUS), a launch system to boost Shuttle payloads to a higher orbit. The Interim Upper Stage was designed as a temporary solution until a space tug became available. Eventually, NASA realized that nothing was replacing the IUS, so it was renamed to "Inertial Upper Stage", preserving the acronym.

I'll mention that this also happened with the 8086 processor. It was intended as an interim processor until the iAPX 432 "micro-mainframe" processor was ready. The iAPX 432 turned out to be a disaster, while the "stopgap" 8086 is still with us as the x86 architecture. ↩

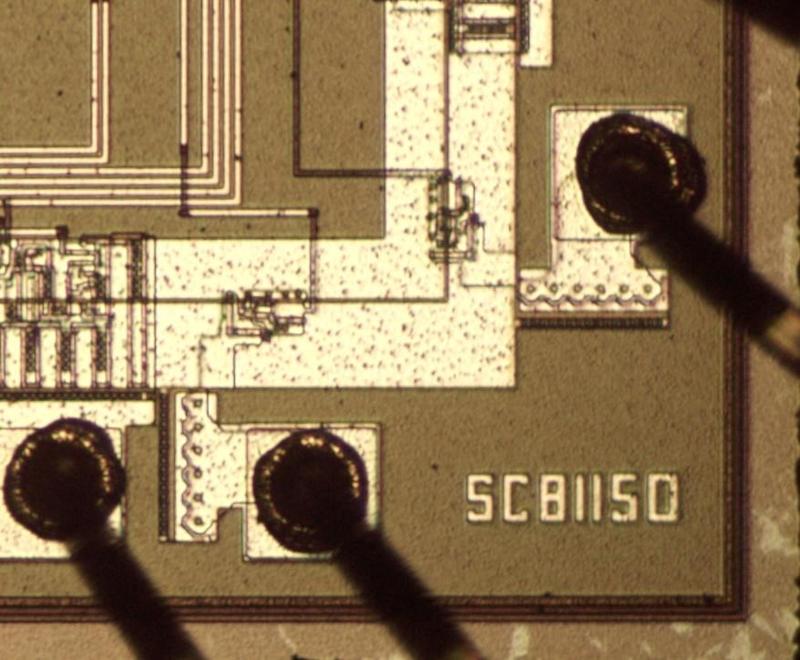

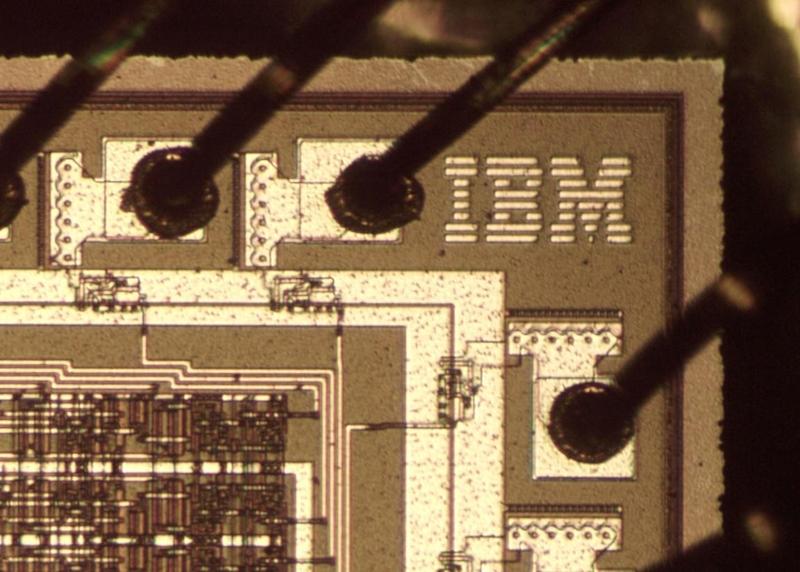

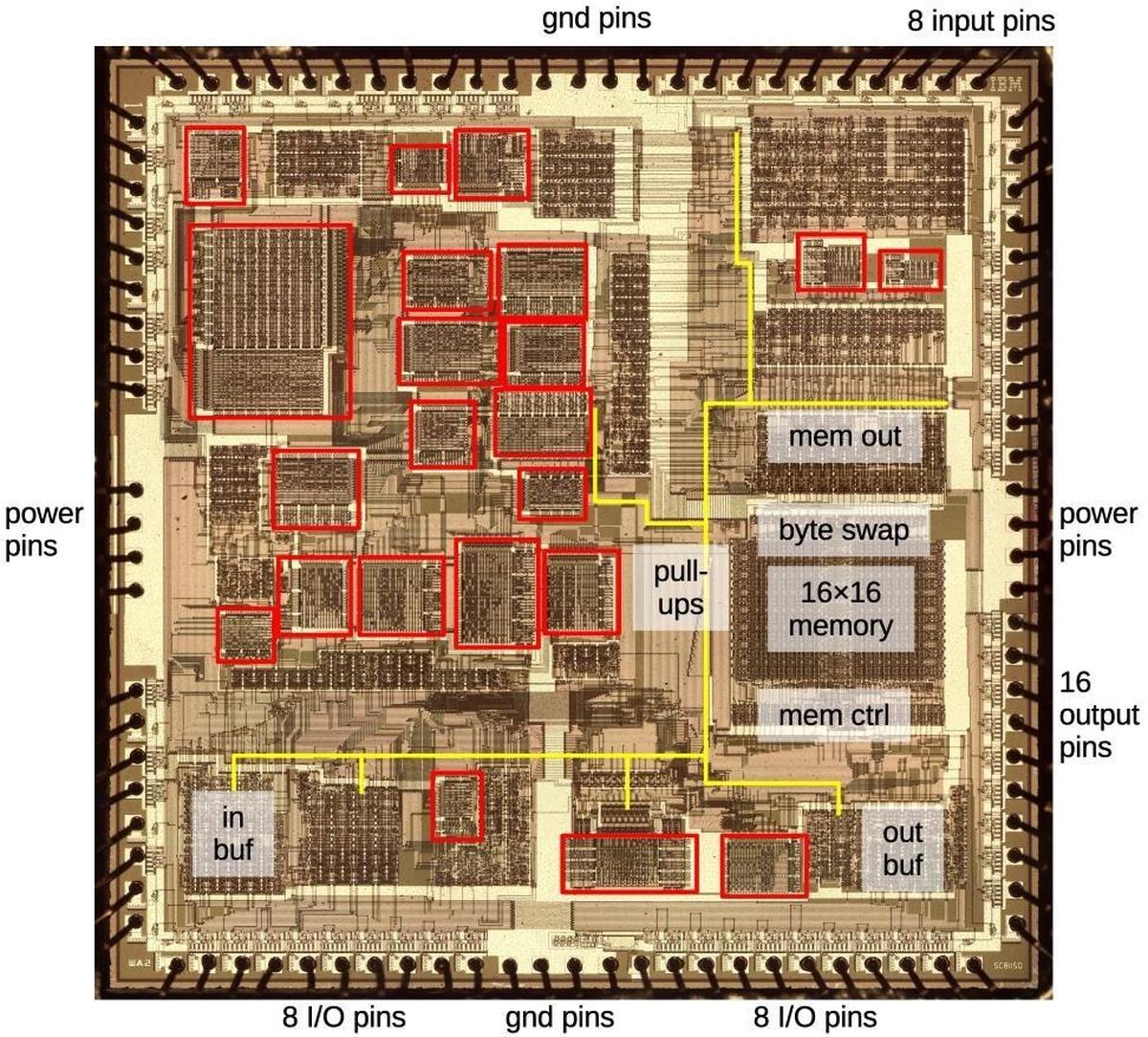

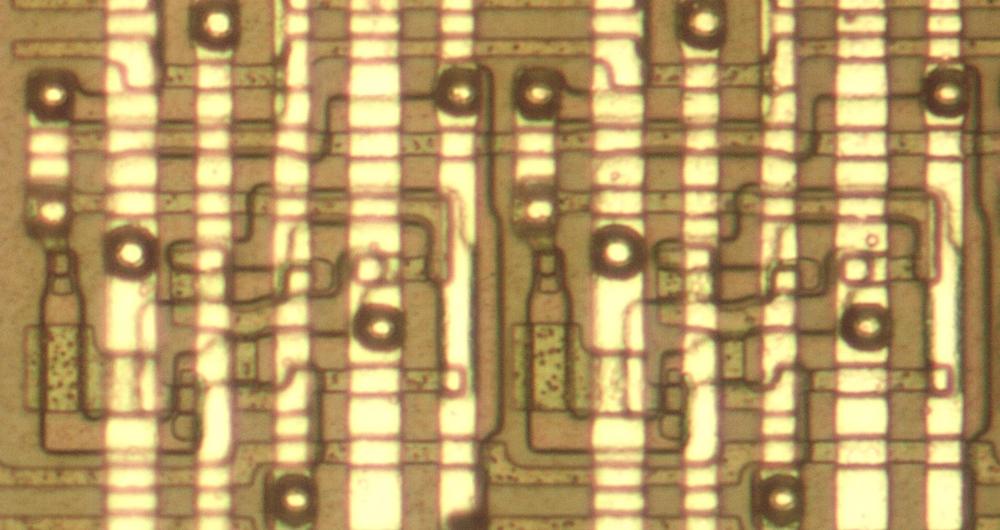

![The Keystone II board. The box is labeled Keystone II FCS [i.e. First Customer Shipment] July 23, 1982. Photo from bitsavers, originally from Bob Roberts. The Keystone II board. The box is labeled Keystone II FCS [i.e. First Customer Shipment] July 23, 1982. Photo from bitsavers, originally from Bob Roberts.](https://static.righto.com/images/ibm-3274/keystone-ii-w600.jpg)